Method for manufacturing thin film composite material

A polymerization method and electrochemical technology, applied in the direction of electrical components, electrolytic capacitors, capacitors, etc., can solve the problems of high conductivity and unsatisfactory stability performance of electrochemical capacitors, and achieve simple process, excellent comprehensive performance and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

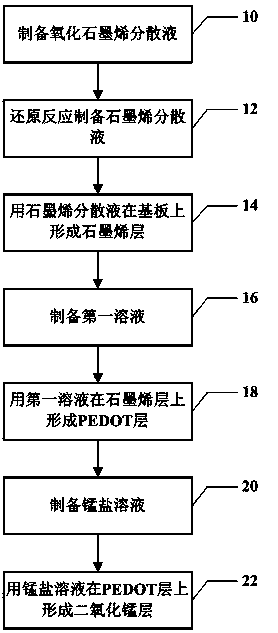

Image

Examples

example 1

[0051] (1) Put the ITO glass into acetone, ethanol, and deionized water for ultrasonication for 20 minutes and dry it for later use; dissolve 5 mg of graphene oxide in 50 ml of deionized water, and ultrasonicate for 2 hours to make it a graphene oxide dispersion. Add 70 μl of ammonia water to the graphene dispersion, add 3 μl of hydrazine hydrate solution after stirring, and react in a water bath at 96°C for 1 hour after fully stirring. After the reaction, a uniform black graphene dispersion is obtained; the graphene dispersion is uniformly Drop-coated on ITO glass, dried under normal temperature and vacuum conditions; obtained graphene layer;

[0052] (2) Dissolve 2.8408g of sodium sulfate particles in 200ml of deionized water, stir evenly with glass, then add 100μl of EDOT monomer dropwise into the solution, stir for 4 hours with magnetic force to dissolve it; work with graphene layer Electrode, the platinum wire electrode is the counter electrode, Ag / AgCl is the reference e...

example 2

[0056] (1) Put the ITO glass into acetone, ethanol, and deionized water for 20 minutes, and dry it for later use; dissolve 10 mg of graphene oxide in 50 ml of deionized water, and ultrasonicate for 2 hours to make it into a graphene oxide dispersion. Add 70 μl of ammonia water to the graphene dispersion, add 6 μl of hydrazine hydrate solution after stirring, and react in a water bath at 96°C for 1 hour after stirring. After the reaction, a uniform black graphene dispersion liquid is obtained; the graphene dispersion liquid is evenly mixed with a rubber dropper. Drop-coated on ITO glass, dried under normal temperature and vacuum conditions; obtained graphene layer;

[0057] (2) Dissolve 2.8408g of sodium sulfate particles in 200ml of deionized water, stir evenly with glass, then add 100μl of EDOT monomer dropwise into the solution, stir for 4 hours with magnetic force to dissolve it; work with graphene layer Electrode, the platinum wire electrode is the counter electrode, Ag / Ag...

example 3

[0061] (1) Put the ITO glass into acetone, ethanol, and deionized water for 20 minutes, and dry it for later use; dissolve 10 mg of graphene oxide in 50 ml of deionized water, and ultrasonicate for 2 hours to make it into a graphene oxide dispersion. Add 70 μl of ammonia water to the graphene dispersion, add 6 μl of hydrazine hydrate solution after stirring, and react in a water bath at 96°C for 1 hour after stirring. After the reaction, a uniform black graphene dispersion liquid is obtained; the graphene dispersion liquid is evenly mixed with a rubber dropper. Drop-coated on ITO glass, dried under normal temperature and vacuum conditions; obtained graphene layer;

[0062] (2) Dissolve 2.8408g of sodium sulfate particles in 200ml of deionized water, stir evenly with glass, then add 100μl of EDOT monomer dropwise into the solution, stir for 4 hours with magnetic force to dissolve it; work with graphene layer Electrode, the platinum wire electrode is the counter electrode, Ag / Ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com