Natural jackfruit powder and preparation method thereof

A technology for jackfruit and jackfruit, which is applied to the field of jackfruit natural fruit powder and the preparation of the jackfruit natural fruit powder, can solve the problems such as the preparation of fruit powder and related products, low processing level and added value, etc., and achieves improved solubility, reduced graininess, Scented effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

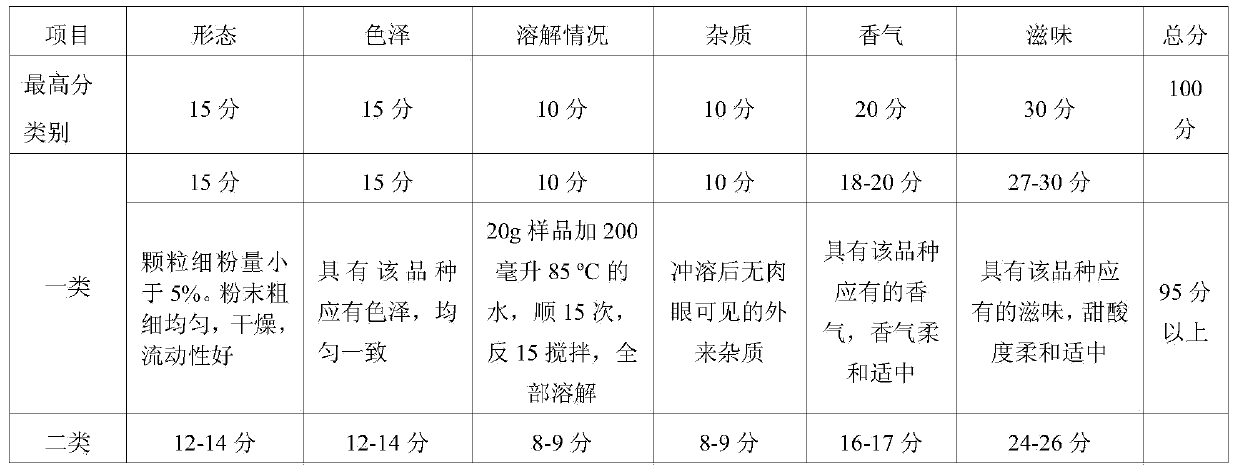

Examples

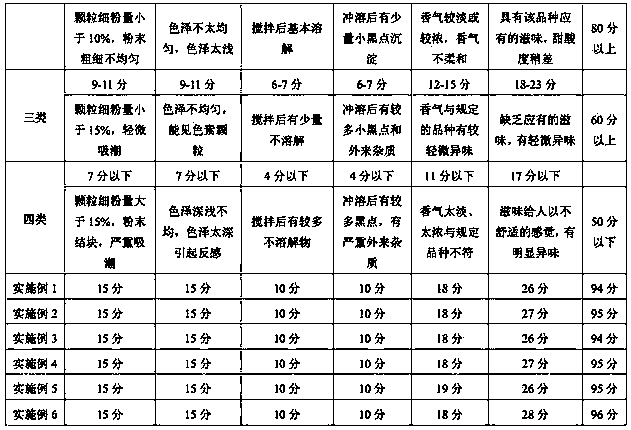

Embodiment 1

[0038] Take about 7Kg of the original jackfruit fruit, peel and remove the core to obtain the pulp that can be used for processing, then add pure water that accounts for 50% of the jackfruit pulp weight percentage and a temperature of 4°C to the pulp, beat it with a fruit and vegetable beater, and make pulp. After 0.08% (accounting for the total solid weight percentage of the jackfruit pulp) plant compound hydrolase at 50°C for 2.5 hours at a constant temperature, filter through an 80-mesh filter cloth, add 70% (accounting for the total solids of the jackfruit pulp) weight percent) of maltodextrin and homogenized quickly, enter the spray drying equipment to prepare fruit powder, control the hot air flow rate of 23.00m 3 *h -1 , feed flow rate 0.30L*h -1 , hot air temperature: 190°C, and then carry out ultrafine grinding on the fruit powder with a vibrating mill. The grinding process is as follows: the filling rate of the grinding medium: 40%, the ball-to-material ratio: 4.0, ...

Embodiment 2

[0040] Take about 7Kg of the original jackfruit fruit, peel and remove the core to obtain the pulp that can be used for processing, then add pure water that accounts for 60% of the jackfruit pulp weight percentage and a temperature of 4°C to the pulp, and beat it with a fruit and vegetable beater to make pulp. After 0.08% (accounting for the total solid weight percentage of the jackfruit pulp) plant compound hydrolase at 47°C for 2.3 hours at a constant temperature, filter through an 80-mesh filter cloth, add 75% (accounting for the total solids of the jackfruit pulp) weight percent) of maltodextrin and homogenized quickly, enter the spray drying equipment to prepare fruit powder, control the hot air flow rate of 27.00m 3 *h ‐1 , feed flow rate 0.27L*h ‐1 , hot air temperature: 188°C, and then carry out ultrafine grinding on the fruit powder with a vibrating mill. The grinding process is as follows: the filling rate of the grinding medium: 47%, the ball-to-material ratio: 4.0...

Embodiment 3

[0042] Take about 7Kg of the original jackfruit fruit, peel and remove the core to obtain the pulp that can be used for processing, then add pure water that accounts for 80% of the jackfruit pulp weight percentage and a temperature of 4°C to the pulp, beat it with a fruit and vegetable beater, and make pulp. After 0.10% (accounting for the total solid weight percentage of the jackfruit pulp) plant compound hydrolase at 47°C for 2.0 hours at a constant temperature, filter through an 80-mesh filter cloth, add 80% (accounting for the total solids of the jackfruit pulp) weight percent) of maltodextrin and homogenized quickly, enter the spray drying equipment to prepare fruit powder, control the hot air flow rate of 24.00m 3 *h -1, feed flow rate 0.25L*h -1 , hot air temperature: 180°C, and then carry out ultrafine grinding on the fruit powder with a vibrating mill. The grinding process is as follows: the filling rate of the grinding medium: 50%, the ball-material ratio: 3.2, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com