Three-element composite photocatalyst and preparation method thereof

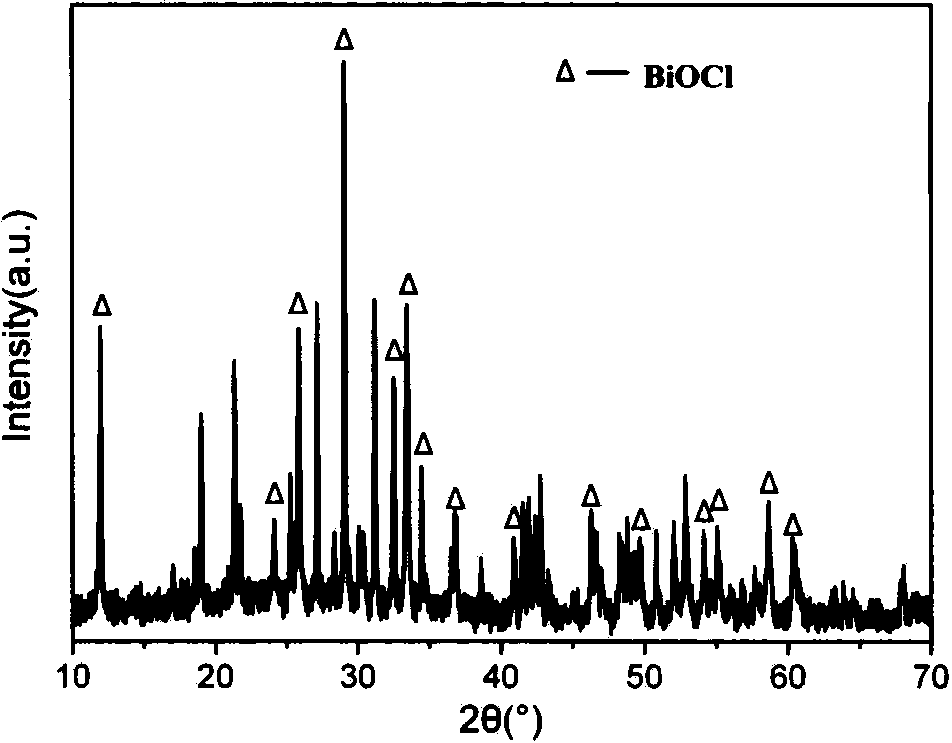

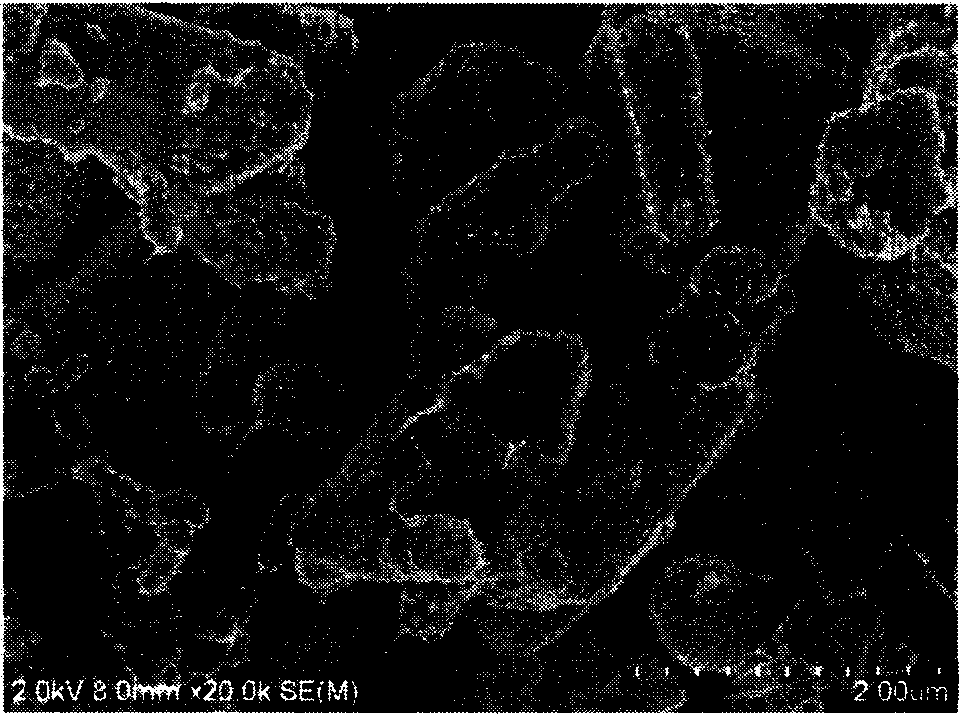

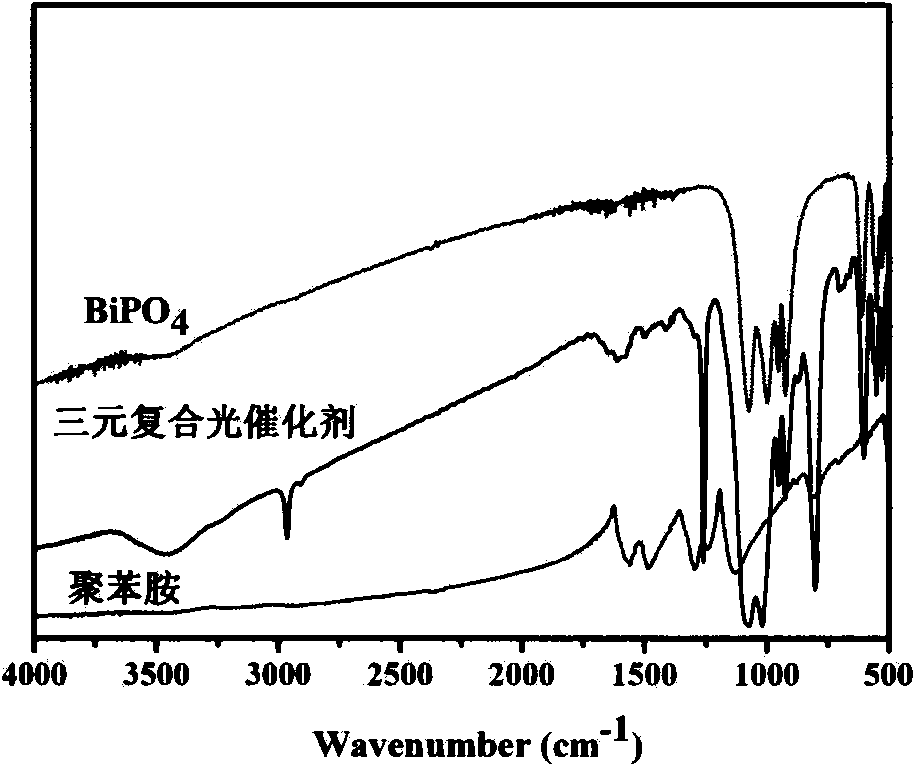

A photocatalyst and ternary compound technology, applied in the field of photocatalysis, can solve the problem of less ternary compound photocatalysts, etc., and achieve the effect of improving photocatalytic activity, high photocatalytic activity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A kind of preparation method of ternary composite photocatalyst of the present invention comprises the following steps:

[0017] (1) Preparation of BiPO 4 : Dissolve a certain amount of bismuth salt in a nitric acid solution with a concentration of 0.1-5 mol / L to form a transparent solution. Under stirring, slowly add 5-20 mL of a 0.1-0.5 mol / L citric acid solution, and continue stirring for 0.5-1 hour. Then add a metered ratio of phosphate solution, in which the concentration of phosphate is controlled at 0.01~0.1mol / L, stir for 0.5~1h, and then transfer to a 50mL stainless steel high-pressure reactor with a polytetrafluoroethylene lining, at 100~240℃ After reacting for 10-30 hours, the obtained product was centrifuged and dried in vacuum at 50-100°C to obtain BiPO 4 catalyst of light;

[0018] (2) Preparation of ternary composite photocatalyst: take the BiPO prepared in step (1) 4 Add 0.1~0.5g of photocatalyst into 50mL hydrochloric acid solution of a certain conce...

Embodiment example 1

[0020] Embodiment example 1: the preparation method of ternary composite photocatalyst of the present invention, comprises the following steps:

[0021] (1) Preparation of BiPO 4 : Dissolve 2mmol bismuth nitrate in 2mol / L nitric acid solution to form a transparent solution, slowly add 20mL of 0.1mol / L citric acid solution under stirring, continue stirring for 0.5h, then add metered ratio of sodium phosphate solution , wherein the concentration of sodium phosphate is controlled at 0.1mol / L, stirred for 0.5h, then transferred to a 50mL stainless steel autoclave lined with polytetrafluoroethylene, reacted at 180°C for 24h, centrifuged the obtained product, and dried at 60°C Vacuum dried to obtain BiPO 4 catalyst of light;

[0022] (2) Preparation of ternary composite photocatalyst: take the BiPO prepared in step (1) 4 Add 0.5 g of photocatalyst to 50 mL of 0.5 mol / L hydrochloric acid solution for ultrasonic dispersion, add 0.025 g of aniline monomer at room temperature, and af...

Embodiment 2

[0024] Implementation example 2: a kind of preparation method of ternary composite photocatalyst of the present invention, comprises the following steps:

[0025] (1) Preparation of BiPO 4 : Dissolve 2mmol bismuth nitrate in 1mol / L nitric acid solution to form a transparent solution, slowly add 10mL of 0.2mol / L citric acid solution under stirring, continue stirring for 0.5h, then add metered ratio of sodium hydrogen phosphate Solution, in which the concentration of sodium hydrogen phosphate is controlled at 0.2mol / L, stirred for 0.5h, then transferred to a 50mL stainless steel autoclave lined with polytetrafluoroethylene, reacted at 190°C for 20h, centrifuged the obtained product, and Vacuum drying at 60°C to obtain BiPO 4 catalyst of light;

[0026] (2) Preparation of ternary composite photocatalyst: take the BiPO prepared in step (1) 4 Add 0.5 g of photocatalyst into 50 mL of 0.4 mol / L hydrochloric acid solution for ultrasonic dispersion, add 0.05 g of aniline monomer at ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com