Resource recovery method of sodium persulfate-sulfuric acid serial copper-containing microetch waste liquor for PCB (Printed Circuit Board)

A technology of sodium persulfate, sulfuric acid system, applied in copper sulfate, chemical instruments and methods, multi-stage treatment of water/sewage, etc., can solve the problems of low treatment cost, low resource utilization, high treatment cost, and achieve low production cost. , Wastewater treatment is simple, the effect of less corrosive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

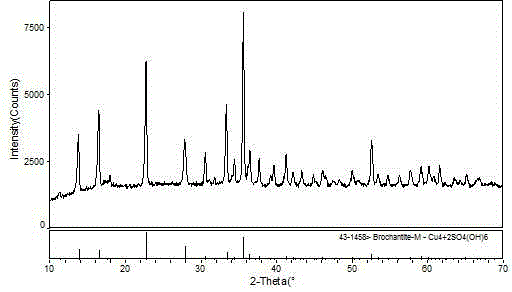

Image

Examples

Embodiment 1

[0026] (1) To the collected PCB sodium persulfate-sulfuric acid system copper-containing micro-etching waste liquid (containing copper 20.36g / L, sodium persulfate 26.69g / L, acidity (in H + Add chlorine-free copper oxide mud to about 1.05g / L), adjust the pH value to 0.5, remove insoluble matter, and obtain clear liquid;

[0027] (2) Prepare a 2 mol / L solution with industrial grade sodium carbonate;

[0028] (3) Add a small amount of distilled water to the reaction kettle, turn on the stirring device, and raise the temperature to 40°C at the same time, then add the clear liquid obtained in step (1) and the sodium carbonate solution obtained in step (2) to the In the reaction kettle, the pH value is controlled at 5.0, and the stirring speed is 200r / min;

[0029] (4) Keep the pH value, reaction temperature and stirring speed constant after the addition of the material and liquid, and continue the reaction for 10 minutes to obtain the reaction product; ...

Embodiment 2

[0033] (1) To the collected PCB sodium persulfate-sulfuric acid system copper-containing micro-etching waste liquid (containing copper 20.36g / L, sodium persulfate 26.69g / L, acidity (in H + Add sodium carbonate to about 1.05g / L), adjust the pH value to 1.0, remove insoluble matter, and obtain clear liquid;

[0034] (2) Prepare a 1.0mol / L solution with reagent grade sodium bicarbonate;

[0035] (3) Add a small amount of the clear liquid obtained in step (1) to the reactor, turn on the stirring device, and raise the temperature to 90°C at the same time, then mix the clear liquid obtained in step (1) and the clear liquid obtained in step (2) The sodium bicarbonate solution is added to the reaction kettle at the same time, the pH is controlled at 3.5, and the stirring speed is 150r / min;

[0036] (4) Keep the pH value, reaction temperature and stirring speed unchanged after the addition of the material and liquid, and continue the reaction for 30 minutes ...

Embodiment 3

[0040] (1) To the collected PCB sodium persulfate-sulfuric acid system copper-containing micro-etching waste liquid (containing copper 20.36g / L, sodium persulfate 26.69g / L, acidity (in H + Add chlorine-free copper oxide mud to about 1.05g / L), adjust the pH value to 0.5, remove insoluble matter, and obtain clear liquid;

[0041] (2) Prepare a 0.5 mol / L solution with industrial grade sodium carbonate;

[0042] (3) Add a small amount of distilled water to the reaction kettle, turn on the stirring device, and raise the temperature to 35°C at the same time, then add the clear liquid obtained in step (1) and the sodium carbonate solution obtained in step (2) to the In the reaction kettle, the pH value is controlled at 6.0, and the stirring speed is 200r / min;

[0043] (4) Keep the pH value, reaction temperature and stirring speed constant after the addition of the material and liquid, and continue the reaction for 50 minutes to obtain the reaction product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com