Method for advanced oxidation treatment of wastewater through complex ferrous activated persulfate or hydrogenperoxosulfate by multicomponent blending

A technology of monoperoxybisulfate and activated persulfate, which is applied in the direction of oxidizing water/sewage treatment, etc., can solve the problems of great difference in capacity, reduced reaction rate, weak capacity, etc., so as to save the use cost and improve the utilization efficiency. , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

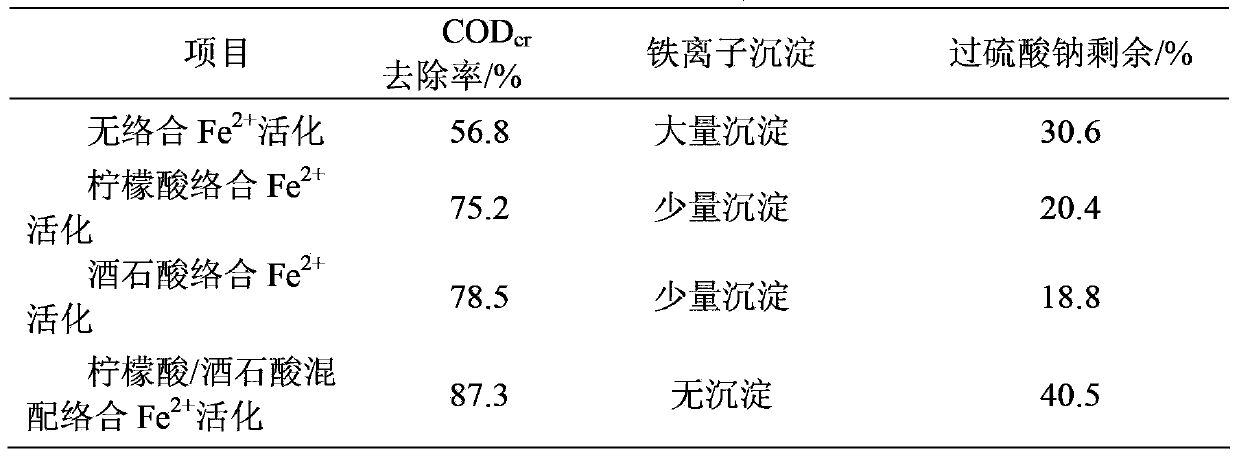

[0025] Under normal temperature conditions, 250mL of printing and dyeing wastewater with a CODcr of 150mg / L and a pH of 3 were taken and marked as 1, 2, 3, and 4 in 4 conical flasks.

[0026](1) Do not add any complexing agent in 1# drug mixing tank, add citric acid as complexing agent in 2# drug mixing tank, add tartaric acid as complexing agent in 3# drug mixing tank, add A mixture of citric acid and tartaric acid is added as a multi-component complexing agent, and the mass ratio of citric acid and tartaric acid is controlled to be 1 / 1.

[0027] (2) 40 minutes before the start of the reaction, add an equal amount of ferrous sulfate to four 125mL drug tanks, fully dissolve, and stir evenly.

[0028] (3) Prepare 125mL sodium persulfate solution in four oxidant dosing tanks respectively.

[0029] (4) Fe in the 1#-4# medicine mixing tank 2+ Add it into the 1-4 conical flask, stir and mix evenly, and at the same time add 125mL sodium persulfate solution from the four oxidant do...

Embodiment 2

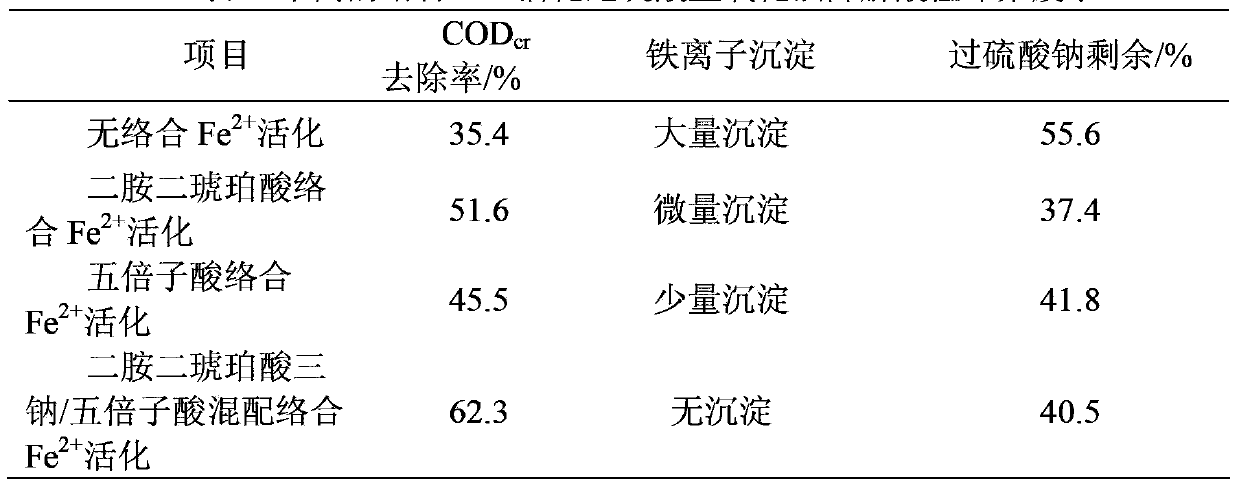

[0035] Under normal temperature conditions, 250mL of printing and dyeing wastewater with a CODcr of 150mg / L and a pH of 10 were taken and marked as 1, 2, 3, and 4 in 4 conical flasks.

[0036] (1) Do not add any complexing agent in the 1# drug mixing tank, add trisodium ethylenediamine disuccinate as a complexing agent in the 2# drug mixing tank, and add gallic acid as a complexing agent in the 3# drug mixing tank , Add a mixture of trisodium ethylenediamine disuccinate and gallic acid into the 4# medicine mixing tank as a multi-component complexing agent. Control the substance ratio of trisodium ethylenediamine disuccinate and gallic acid to be 1 / 2.

[0037] (2) 40 minutes before the start of the reaction, add an equal amount of ferrous sulfate to four 125mL drug tanks, fully dissolve, and stir evenly.

[0038] (3) Prepare 125mL sodium persulfate solution in four oxidant dosing tanks respectively.

[0039] (4) Fe in the 1#-4# medicine mixing tank 2+ Add it into the 1-4 con...

Embodiment 3

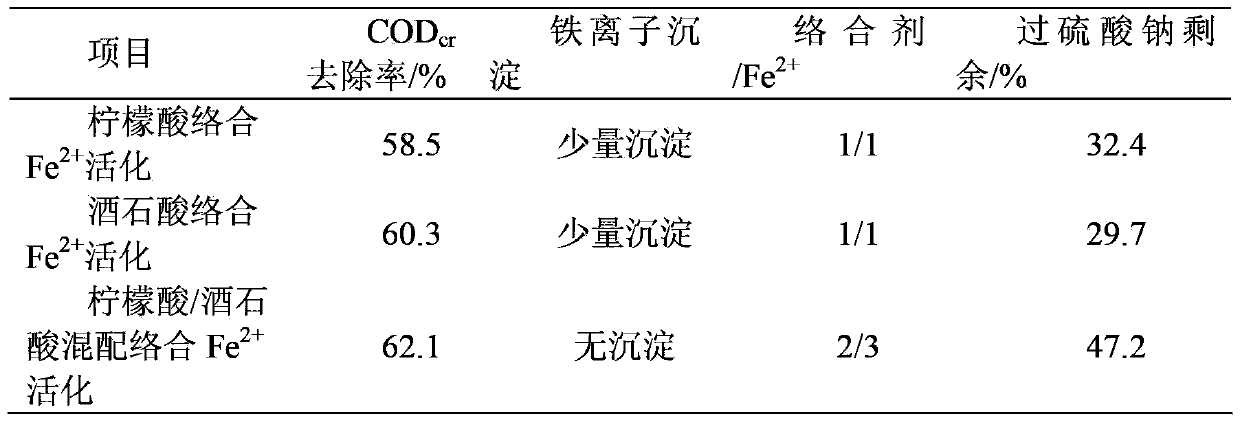

[0045] Under normal temperature conditions, 250mL of printing and dyeing wastewater with a CODcr of 150mg / L and a pH of 7.5 were taken and marked as 1, 2, and 3 in three Erlenmeyer flasks.

[0046] (1) Add citric acid as a complexing agent in the 1# medicine mixing tank, add tartaric acid as a complexing agent in the 2# medicine mixing tank, and add a mixture of citric acid and tartaric acid in the 3# medicine mixing tank as a multi-component complexing agent. The ratio of substances controlling citric acid and tartaric acid is 1 / 2.

[0047] (2) 40 minutes before the start of the reaction, add an equal amount of ferrous sulfate to three 125mL drug tanks, fully dissolve, and stir evenly.

[0048] (3) Prepare 125mL sodium persulfate solution in three oxidant dosing tanks respectively.

[0049] (4) Fe in the 1#-3# medicine mixing tank 2+ Add it into the 1-3 conical flask, stir and mix evenly, and at the same time add 125mL sodium persulfate solution from the three oxidant dosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com