Cement clinker and preparation process thereof

A technology for cement clinker and preparation process, which is applied in cement production and other directions, can solve the problems of polluting environmental resources, easily generating dust, and polluting the environment, and achieves the effects of protecting the environment, avoiding pollution, and reducing prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

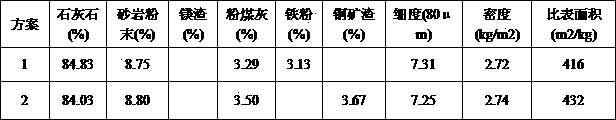

Embodiment 1

[0038] A cement clinker is prepared from raw materials in the following weight ratios: limestone 56.47; sandstone powder 6.37; magnesium slag 7.45; fly ash 2.36; copper slag 1.54.

[0039] The manufacture technique of above-mentioned a kind of cement clinker:

[0040] The first step is to collect limestone, sandstone powder, magnesium slag, fly ash and copper slag, and then mix them according to the following weight ratios: limestone 56.47; sandstone powder 6.37; magnesium slag 7.45; fly ash 2.36; copper slag 1.54;

[0041] In the second step, the limestone, sandstone powder, magnesium slag, fly ash and copper slag mixed in the first step are dried and ground to obtain raw meal powder;

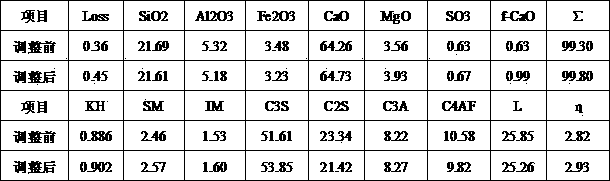

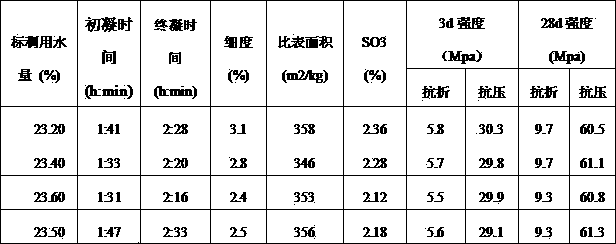

[0042] In the third step, the raw meal powder in the second step is calcined to obtain clinker. Before calcination, the lime saturation coefficient KH value of the cement clinker from 0.886 is increased by 0.01, and the silicon oxygen ratio SM value is increased from 2.46 by 0.05. The valve o...

Embodiment 2

[0044] A cement clinker is prepared from the following raw materials by weight: limestone 60.37; sandstone powder 9.05; magnesium slag 9.65; fly ash 3.76; copper slag 4.75.

[0045] The manufacture technique of above-mentioned a kind of cement clinker:

[0046] The first step is to collect limestone, sandstone powder, magnesium slag, fly ash and copper slag, and then mix them according to the following weight ratios: limestone 60.37; sandstone powder 9.05; magnesium slag 9.65; fly ash 3.76; copper slag 4.75;

[0047] In the second step, the limestone, sandstone powder, magnesium slag, fly ash and copper slag mixed in the first step are dried and ground to obtain raw meal powder;

[0048] In the third step, the raw meal powder in the second step is calcined to obtain clinker. Before calcination, the lime saturation coefficient KH value of the cement clinker is increased from 0.886 to 0.013, and the silicon oxygen ratio SM value is increased from 2.46 by 0.16. The valve opening...

Embodiment 3

[0050] A cement clinker is prepared from the following raw materials by weight: limestone 68.82; sandstone powder 11.42; magnesium slag 12.18; fly ash 4.71; copper slag 2.87.

[0051] The manufacture technique of above-mentioned a kind of cement clinker:

[0052] The first step is to collect limestone, sandstone powder, magnesium slag, fly ash and copper slag, and then mix them according to the following weight ratios: limestone 68.82; sandstone powder 11.42; magnesium slag 12.18; fly ash 4.71; copper slag 2.87;

[0053] In the second step, the limestone, sandstone powder, magnesium slag, fly ash and copper slag mixed in the first step are dried and ground to obtain raw meal powder;

[0054] In the third step, the raw meal powder in the second step is calcined to obtain clinker. Before calcination, the lime saturation coefficient KH value of the cement clinker is increased from 0.886 to 0.016, and the silicon oxygen ratio SM value is increased from 2.46 by 0.11. The valve ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com