Composite aluminophosphate binder with good durability and bonding method thereof

A composite aluminum phosphate and aluminum phosphate technology, which is applied in building maintenance, construction, building construction, etc., can solve the problems of poor freeze-thaw cycle resistance and dry-wet cycle resistance, thermal stability, and long-term Poor chemical stability, large shrinkage of organic polymer materials and other problems, to achieve good long-term chemical stability, rapid development of mechanical properties, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

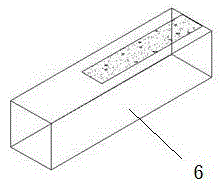

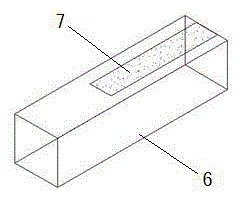

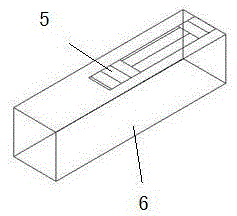

[0035] Figure 1 to Figure 5 The reference numerals in the figure are: composite aluminophosphate binder and filter layer 1 of concrete structure; composite aluminophosphate binder and concrete structure interface 2; composite aluminophosphate binder layer 3; composite phosphorus Aluminate binder and concrete structure bonding interface 4; fiber reinforced composite plastic cloth 5; concrete structure 6; composite aluminophosphate binder 7.

[0036] A composite aluminophosphate binder with good durability properties comprising:

[0037] 15% to 75% of A component, A component is made of 62.5, 72.5 and 82.5 aluminophosphate cementitious materials;

[0038] 10% to 20% of component B, component B is magnesium oxide (MgO), zinc oxide (ZnO), aluminum oxide (Al 2 o 3 ), iron oxide (Fe 2 o 3 ) in any one or any combination thereof;

[0039] 20% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com