Super-soft and high-flatness paper-making industry transmission belt

A flatness and paper-making technology, applied in household appliances, other household appliances, closed-loop items, etc., can solve problems such as poor strength, high contact friction coefficient between conveyor belt and metal, easy warping, etc., to ensure strength and stable size , the effect of not easy to warp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

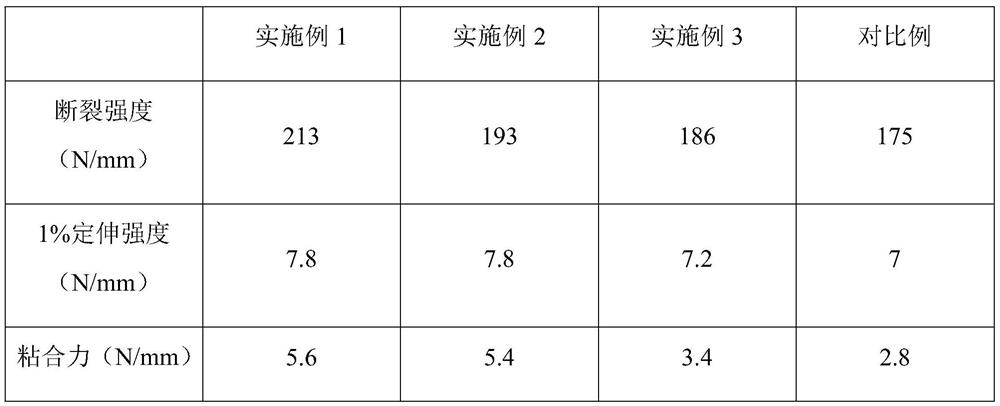

Examples

Embodiment 1

[0036] A paper-making transmission belt with super softness and high flatness mainly comprises, by weight parts: 20 parts of an upper friction layer, 15 parts of an adhesive layer and 40 parts of a composite skeleton layer.

[0037] A preparation method of a papermaking transmission belt with super softness and high flatness, the preparation method of the papermaking transmission belt with super softness and high flatness mainly includes the following steps:

[0038] (1) by weight, take successively 60 parts of carboxylated nitrile rubber raw rubber, 20 parts of white carbon black, 5 parts of rubber oil, 4 parts of antistatic agent, 5 parts of vulcanization aids and 6 parts of rubber protective agent, Put carboxylated nitrile rubber raw rubber in a banbury mixer, banbury for 2 minutes, add reinforcing agent white carbon black to the banbury mixer, continue banbury for 3 minutes, then add rubber oil, antistatic agent, vulcanization aid, Rubber protective agent, continue to banb...

Embodiment 2

[0047] A paper-making transmission belt with super softness and high flatness mainly comprises, by weight parts: 20 parts of an upper friction layer, 15 parts of an adhesive layer and 40 parts of a composite skeleton layer.

[0048] A preparation method of a papermaking transmission belt with super softness and high flatness, the preparation method of the papermaking transmission belt with super softness and high flatness mainly includes the following steps:

[0049] (1) by weight, take successively 60 parts of carboxylated nitrile rubber raw rubber, 20 parts of white carbon black, 5 parts of rubber oil, 4 parts of antistatic agent, 5 parts of vulcanization aids and 6 parts of rubber protective agent, Put carboxylated nitrile rubber raw rubber in a banbury mixer, banbury for 2 minutes, add reinforcing agent white carbon black to the banbury mixer, continue banbury for 3 minutes, then add rubber oil, antistatic agent, vulcanization aid, Rubber protective agent, continue to banb...

Embodiment 3

[0058] A paper-making transmission belt with super softness and high flatness mainly comprises, by weight parts: 20 parts of an upper friction layer, 15 parts of an adhesive layer and 40 parts of a composite skeleton layer.

[0059] A preparation method of a papermaking transmission belt with super softness and high flatness, the preparation method of the papermaking transmission belt with super softness and high flatness mainly includes the following steps:

[0060] (1) by weight, take successively 60 parts of carboxylated nitrile rubber raw rubber, 20 parts of white carbon black, 5 parts of rubber oil, 4 parts of antistatic agent, 5 parts of vulcanization aids and 6 parts of rubber protective agent, Put carboxylated nitrile rubber raw rubber in a banbury mixer, banbury for 2 minutes, add reinforcing agent white carbon black to the banbury mixer, continue banbury for 3 minutes, then add rubber oil, antistatic agent, vulcanization aid, Rubber protective agent, continue to banb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com