Method for improving property of dry pressing isotropic permanent magnetic ferrite

A permanent magnet ferrite and isotropic technology, which is applied in the preparation of permanent magnet ferrite magnetic materials and the field of squaring permanent magnet ferrite magnetic tiles, can solve the problems of increasing the cost of raw materials, less crustal reserves, difficulty in refining, etc., so as to improve the reaction Activity, improve magnetic properties, doping uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

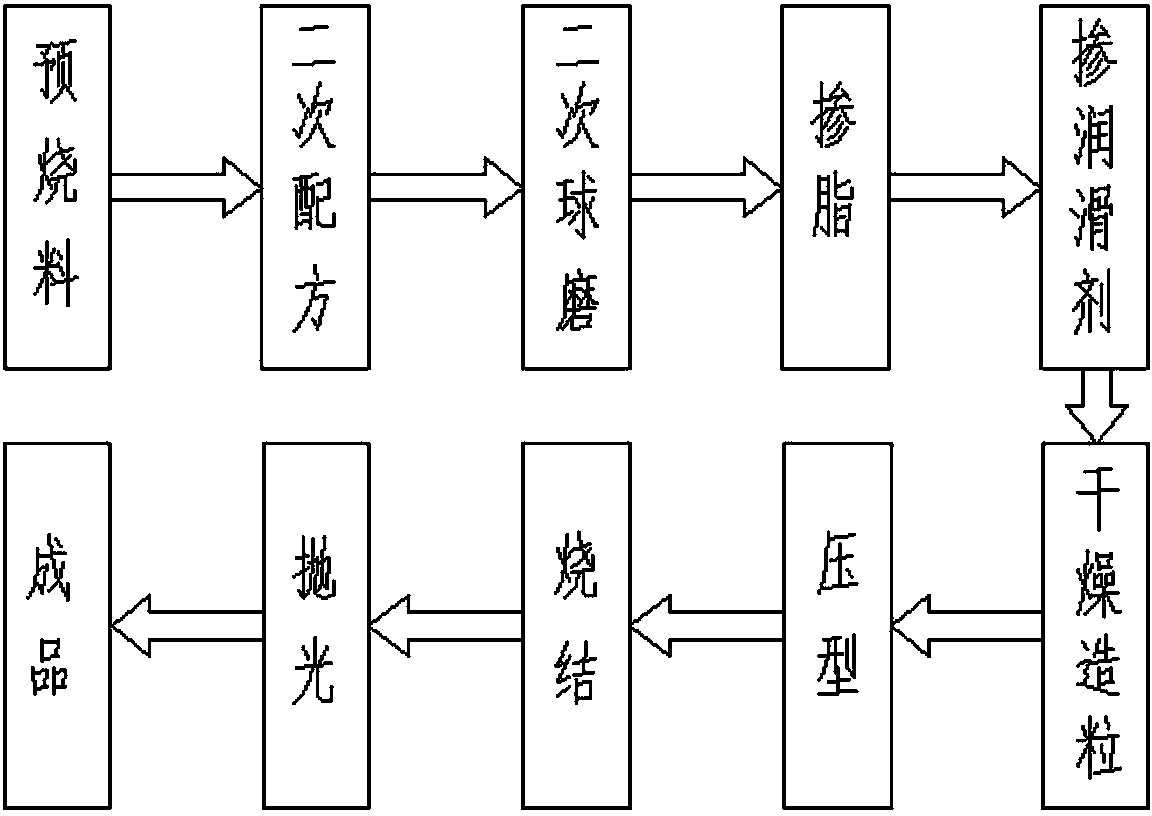

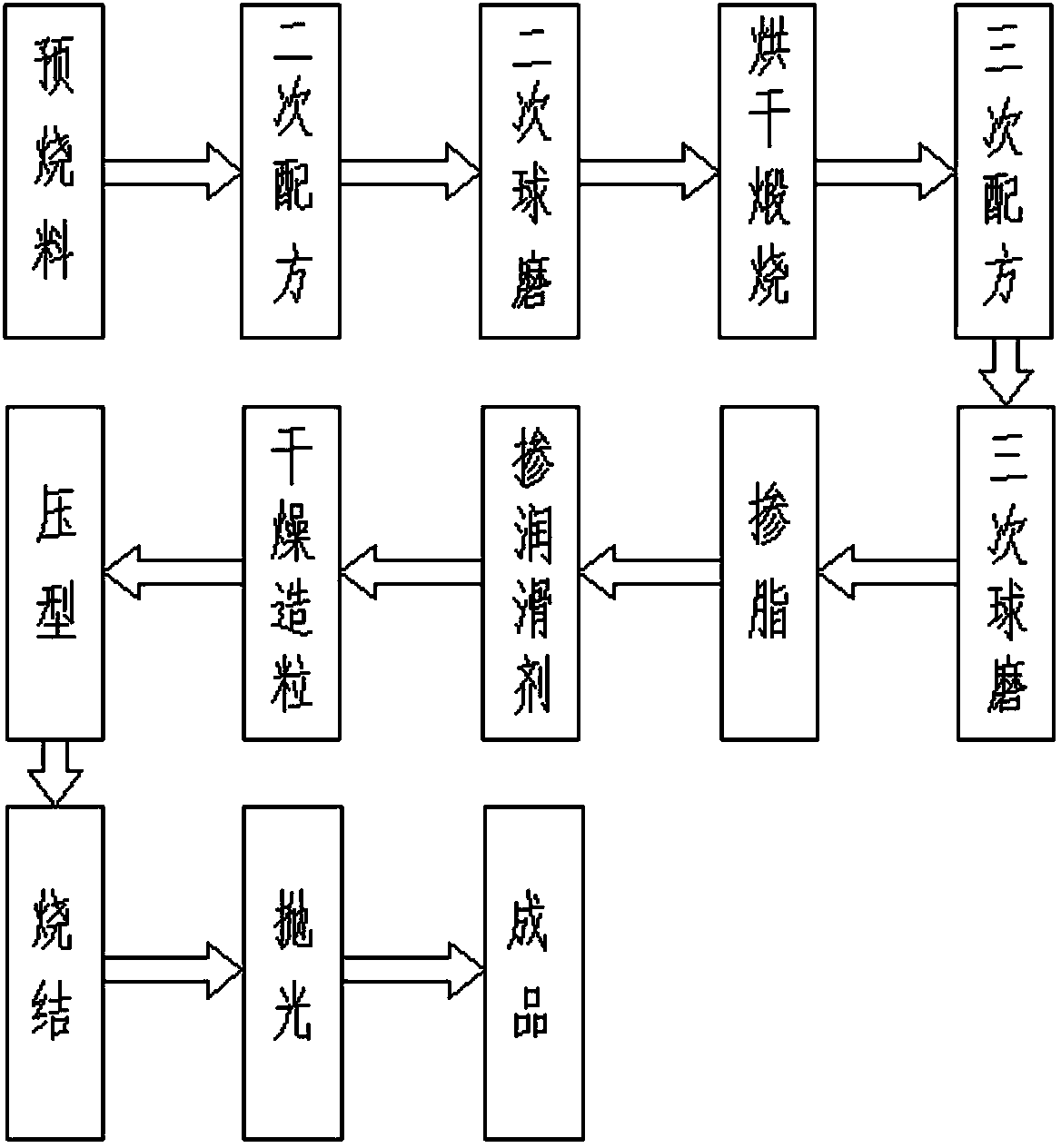

Method used

Image

Examples

Embodiment 1

[0035] Weigh 150 g of strontium ferrite calcined material, add 1.20 g of calcium carbonate, 0.30 g of boric acid, 0.15 g of kaolin and 180 ml of water, ball mill for 6 h, filter, and dry at 105 °C; then calcined at 850 °C for 6 h, Then add 0.75 g of calcium carbonate, 0.30 g of boric acid, 0.6 g of sodium dodecylsulfonate and 180 ml of water, and ball mill at 400 r / min for 12 h to obtain ultrafine permanent magnet ferrite slurry with organic coating on the surface material. The average particle size measured by sampling is 0.58um, and the BET is 19.8 g / m 2 . Add 0.30 g of PVA that has been dissolved in advance, continue ball milling for 3 hours, then filter, dry at 80°C, add calcium stearate, granulate, and press to obtain a ferrite magnet green body; Keep the temperature at 1220°C for 2 hours, cool with the furnace, and then polish to obtain the ferrite magnet for motors. This magnet is assembled into a motor, and the Ec value of the test after magnetization is 1.80 V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com