Cellulose higher fatty acid ester and preparation method thereof

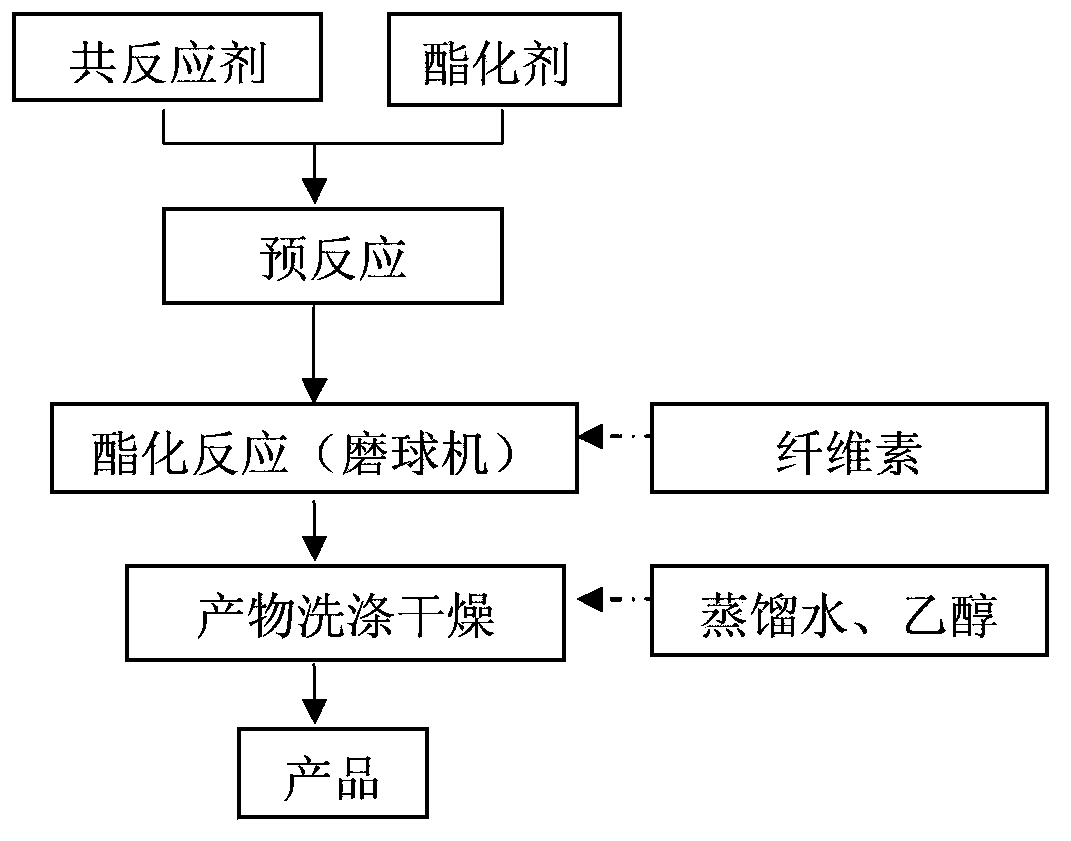

A fatty acid ester and cellulose technology, which is applied in the field of cellulose high fatty acid ester and its preparation, can solve the problems of incomplete solid phase reaction, complicated screening and washing, and long reaction time, so as to increase the reaction contact surface and shorten the reaction time. Reaction time, the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, the weight ratio of each component of the cellulose higher fatty acid ester, cellulose, esterification agent, and co-reactant is 100g:200g:500g. The cellulose is sugarcane cellulose; the esterification agent is octanoic acid (C8); and the co-reactant is acetic anhydride.

[0022] a. Pre-reaction: According to the weight ratio of cellulose, esterifying agent, and co-reactant as 100g:200g:500g, respectively weigh sugarcane cellulose, caprylic acid (C8) esterifying agent, and acetic anhydride co-reactant. After mixing with the co-reactant, pre-react at 65° C. for 15 minutes, and then mix the cellulose with the pre-reacted reactant evenly to obtain a mixed material.

[0023] b. Esterification reaction: Add the mixed material obtained in step a into a ball mill, and carry out esterification reaction for 60 minutes at a stirring speed of 250rmp and a temperature of 65°C to obtain a reaction product, which is washed and dried The cellulose higher fatty aci...

Embodiment 2

[0026] In this embodiment, the weight ratio of the components of the cellulose higher fatty acid ester, cellulose, esterifying agent, and co-reactant, is 100g:100g:400g. The cellulose is tapioca cellulose; the esterification agent is lauric acid (C12); and the co-reactant is p-toluenesulfonyl chloride.

[0027] a, pre-reaction: according to the weight ratio of cellulose, esterifying agent, co-reactant is 100g:100g:400g, take cassava cellulose, lauric acid (C12) esterifying agent, p-toluenesulfonyl chloride co-reactant respectively, and The esterification agent and the co-reactant are mixed and pre-reacted at 50° C. for 18 minutes, and then the cellulose and the pre-reacted reactant are uniformly mixed to obtain a mixed material.

[0028] b. Esterification reaction: Add the mixed material obtained in step a into a ball mill, and carry out esterification reaction for 40 minutes under the conditions of a stirring speed of 300rmp and a temperature of 55°C to obtain a reaction produc...

Embodiment 3

[0031] In this embodiment, the weight ratio of each component of the cellulose higher fatty acid ester, cellulose, esterification agent, and co-reactant is 100g:150g:300g. The cellulose is a mixture of sugarcane cellulose and tapioca cellulose; the esterification agent is a mixture of lauric acid (C12) and octanoic acid (C8); and the co-reactant is trichloroacetic anhydride.

[0032] a. Pre-reaction: According to the weight ratio of cellulose, esterification agent and co-reactant as 100g:150g:300g, weigh sugarcane cellulose and tapioca cellulose (the ratio of both is 50g:50g), lauric acid (C12) and octanoic acid (C8) esterification agent (the ratio of the two is 75g:75g), trichloroacetic acid anhydride co-reactant, the esterification agent and co-reactant are mixed and pre-reacted at 70°C for 107min, and then the cellulose Mix evenly with the pre-reacted reactant to obtain a mixed material.

[0033] b. Esterification reaction: Add the mixed material obtained in step a into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com