Non-transparent polyvinyl chloride corrugated sheet and preparation method thereof

A technology of polyvinyl chloride and corrugated board, which is applied in the field of packaging materials, can solve the problems of general flame retardancy, etc., and achieve the effect of good low-temperature folding resistance and superior physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

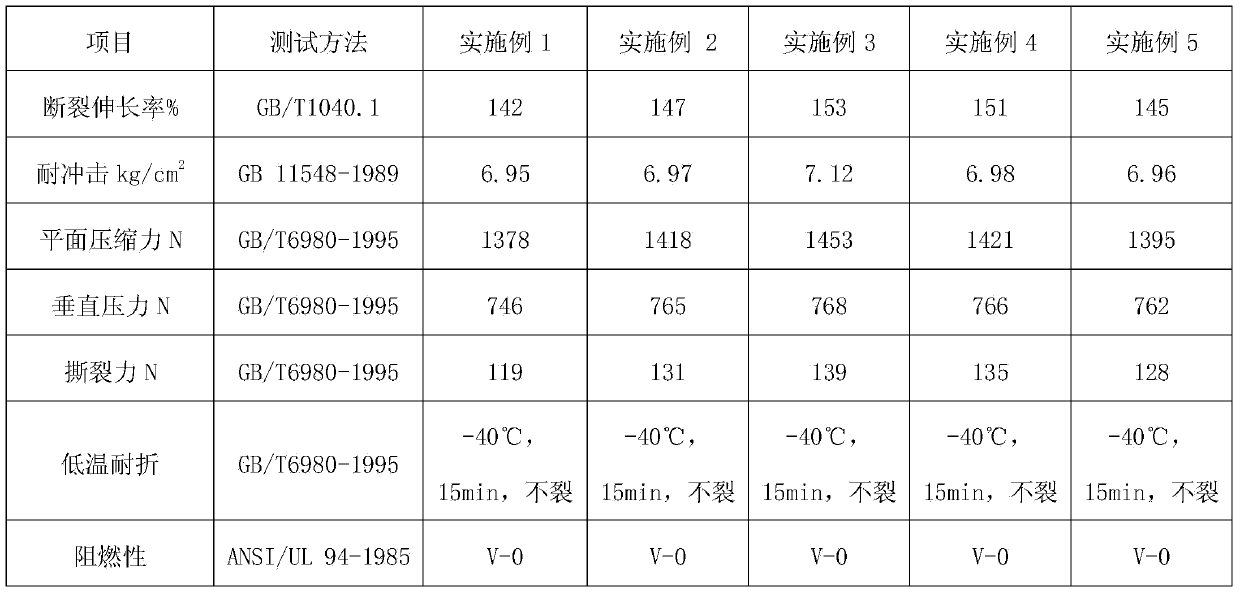

Examples

Embodiment 1

[0014] An opaque polyvinyl chloride corrugated board, comprising by weight components: 80 parts of polyvinyl chloride, 1 part of barium stearate, 0.5 part of zinc stearate, 0.5 part of stearic acid, 0.5 part of triphenyl phosphate, polyvinyl chloride 0.2 part of ammonium phosphate, 0.5 part of paraffin, 0.5 part of diphenyl phosphite, 0.5 part of butyl stearate, 0.2 part of ultraviolet absorber, 0.5 part of coloring agent, 0.2 part of organic phosphite, and 1 part of epoxy soybean oil.

[0015] The opaque polyvinyl chloride corrugated board described above is prepared by the following steps:

[0016] (1) Weigh each component according to parts by weight;

[0017] (2) Stir and mix each component in a mixer, where the stirring temperature is 50°C, the stirring speed is 70 rpm, and the time is 15 minutes;

[0018] (3) After the mixing is completed, put the mixed material in a masticator for mastication, wherein the mastication temperature is 120°C, and the time is 45 minutes;

...

Embodiment 2

[0021] An opaque polyvinyl chloride corrugated board, comprising by weight components: 92 parts of polyvinyl chloride, 2 parts of barium stearate, 0.6 part of zinc stearate, 0.6 part of stearic acid, 0.6 part of triphenyl phosphate, polyvinyl chloride 0.3 parts of ammonium phosphate, 0.7 parts of paraffin, 0.6 parts of diphenyl phosphite, 0.8 parts of butyl stearate, 0.3 parts of ultraviolet absorber, 1 part of coloring agent, 0.3 parts of organic phosphite, 1.2 parts of epoxidized soybean oil.

[0022] The opaque polyvinyl chloride corrugated board described above is prepared by the following steps:

[0023] (1) Weigh each component according to parts by weight;

[0024] (2) Stir and mix each component in a mixer, where the stirring temperature is 53°C, the stirring speed is 75 rpm, and the time is 18 minutes;

[0025] (3) After the mixing is completed, put the mixed material in a masticator for masticating, wherein the masticating temperature is 122°C, and the time is 50 mi...

Embodiment 3

[0028] An opaque polyvinyl chloride corrugated board, comprising by weight components: 95 parts of polyvinyl chloride, 3 parts of barium stearate, 0.8 part of zinc stearate, 0.7 part of stearic acid, 0.7 part of triphenyl phosphate, polyvinyl chloride 0.4 parts of ammonium phosphate, 0.8 parts of paraffin, 0.7 parts of diphenyl phosphite, 1.2 parts of butyl stearate, 0.5 parts of ultraviolet absorber, 1.3 parts of coloring agent, 0.4 parts of organic phosphite, 1.6 parts of epoxy soybean oil.

[0029] The opaque polyvinyl chloride corrugated board described above is prepared by the following steps:

[0030] (1) Weigh each component according to parts by weight;

[0031] (2) Stir and mix each component in a mixer, where the stirring temperature is 55°C, the stirring speed is 80 rpm, and the time is 20 minutes;

[0032] (3) After the mixing is completed, put the mixed material in a masticator for mastication, wherein the mastication temperature is 125°C, and the time is 60 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear load | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com