Genetically engineered bacterium for producing acetoin as well as construction method and application thereof

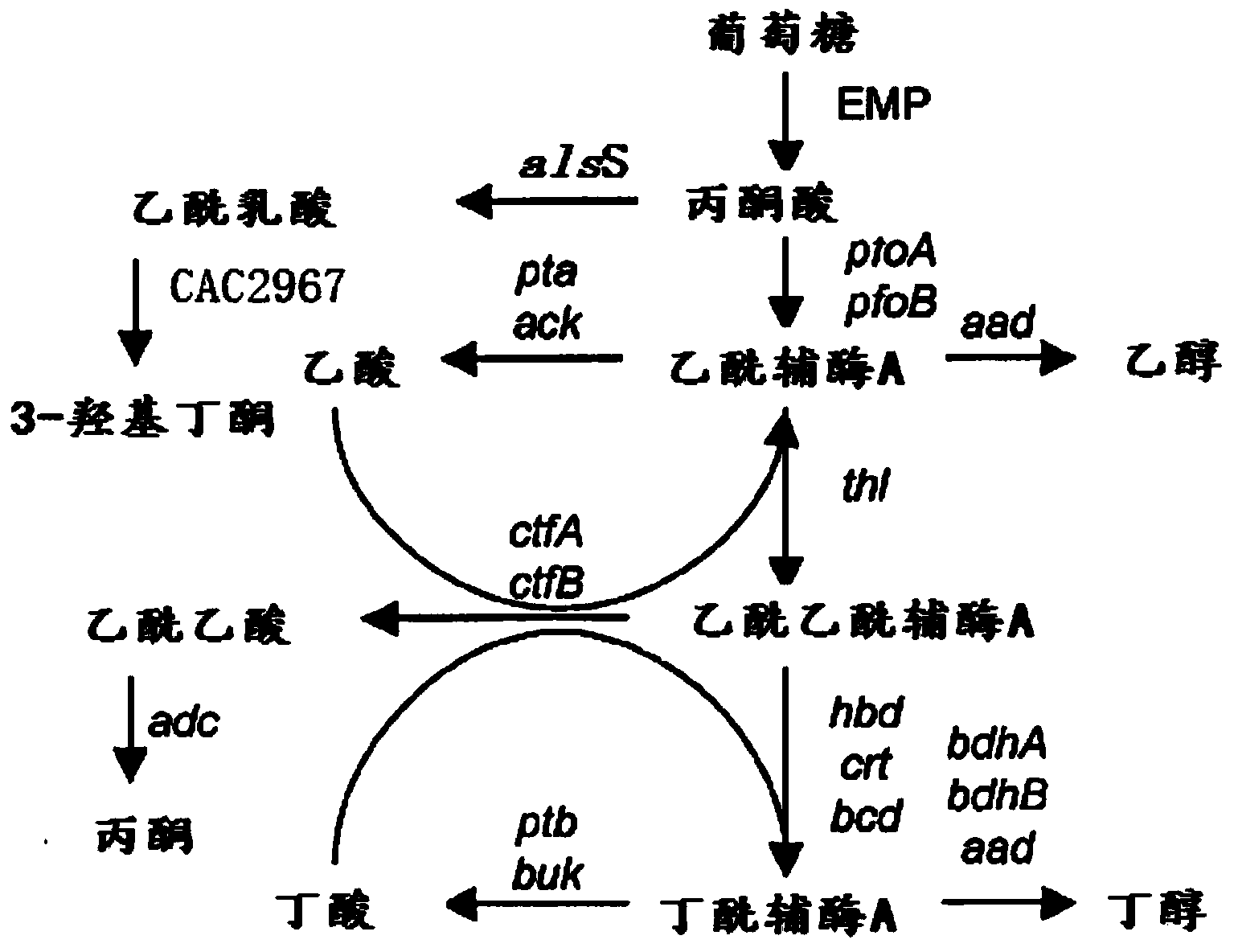

A technology of genetically engineered bacteria and hydroxybutanone, which is applied in the directions of genetic engineering, microorganism-based methods, applications, etc., can solve the problems of not increasing the yield of 3-hydroxybutanone, and achieve the effects of increasing yield and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Construction of Clostridium acetobutylicum containing the expression plasmid of the acetolactate decarboxylase gene CAC2967.

[0037] The bacterial genome kit was used to extract the genomic DNA of Clostridium acetobutylicum ATCC824 in the middle and late stages of logarithmic growth, and the acetolactate decarboxylase gene CAC2967 was amplified by PCR with the following primers:

[0038] ALDC-s CATATG ATTGAAGAAGTGATCCCTAATCAT (the underlined part is the NdeI recognition site);

[0039] ALDC—as GAAATAAGTAAAGTTGAGAAATAA CATATG (The underlined part is the NdeI recognition site).

[0040] The high-efficiency fidelity enzyme Primerstart of TAKARA Company was used for PCR amplification, and the amplification program was: 95°C for 3min; 98°C for 10s, 55°C for 15s, 72°C for 1min, 30 cycles; 72°C for 10min. After the PCR product was sequenced, its sequence was determined as shown in SEQ ID No:1.

[0041] After the obtained PCR product was purified and recovered...

Embodiment 2

[0044] Example 2: Construction of Clostridium acetobutylicum containing the expression plasmid of the acetolactate decarboxylase gene BSU36000.

[0045] Bacillus subtilis CGMCC No.3720 (recorded in Chinese patent 201010171377.5) was extracted using a bacterial genome kit. The acetolactate decarboxylase gene BSU36000 was amplified by PCR with the following primers:

[0046] BSU36000-s CATATG ATGAAACGAGAAAGCAACATTC (the underlined part is the NdeI recognition site);

[0047] BSU36000-as TGAAGGAAGCCCTGAATAA CATATG (The underlined part is the NdeI recognition site). The sequence of the amplified product is determined as shown in SEQ ID No:2 after sequencing. The amplified product was introduced into Clostridium acetobutylicum according to the method in Example 1 to obtain a recombinant Clostridium acetobutylicum containing the pIMP1-BSU36000 plasmid, which was named C. acetobutylicum B3 (pIMP1-BSU36000).

Embodiment 3

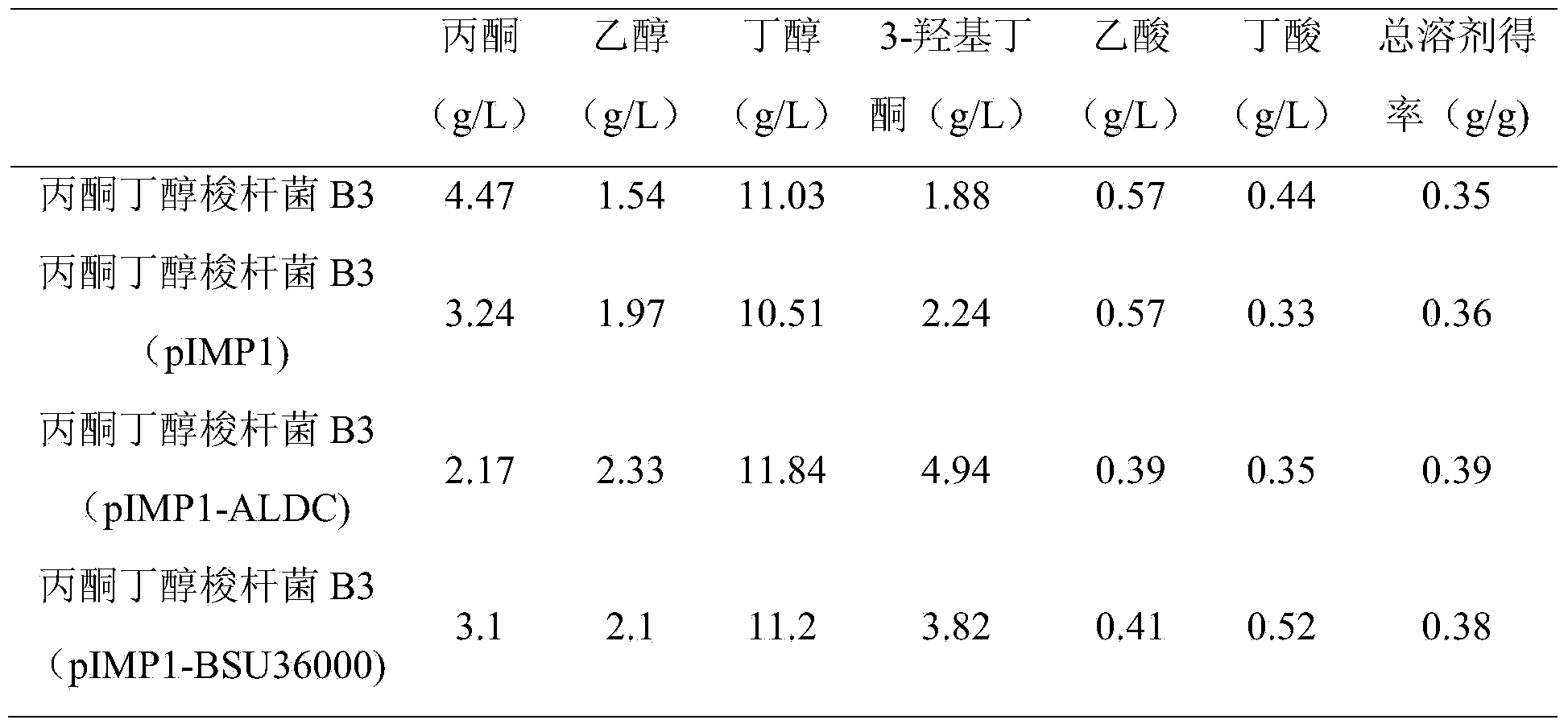

[0048] Example 3: Fermentative production of ABE and 3-hydroxybutanone by genetically engineered bacteria.

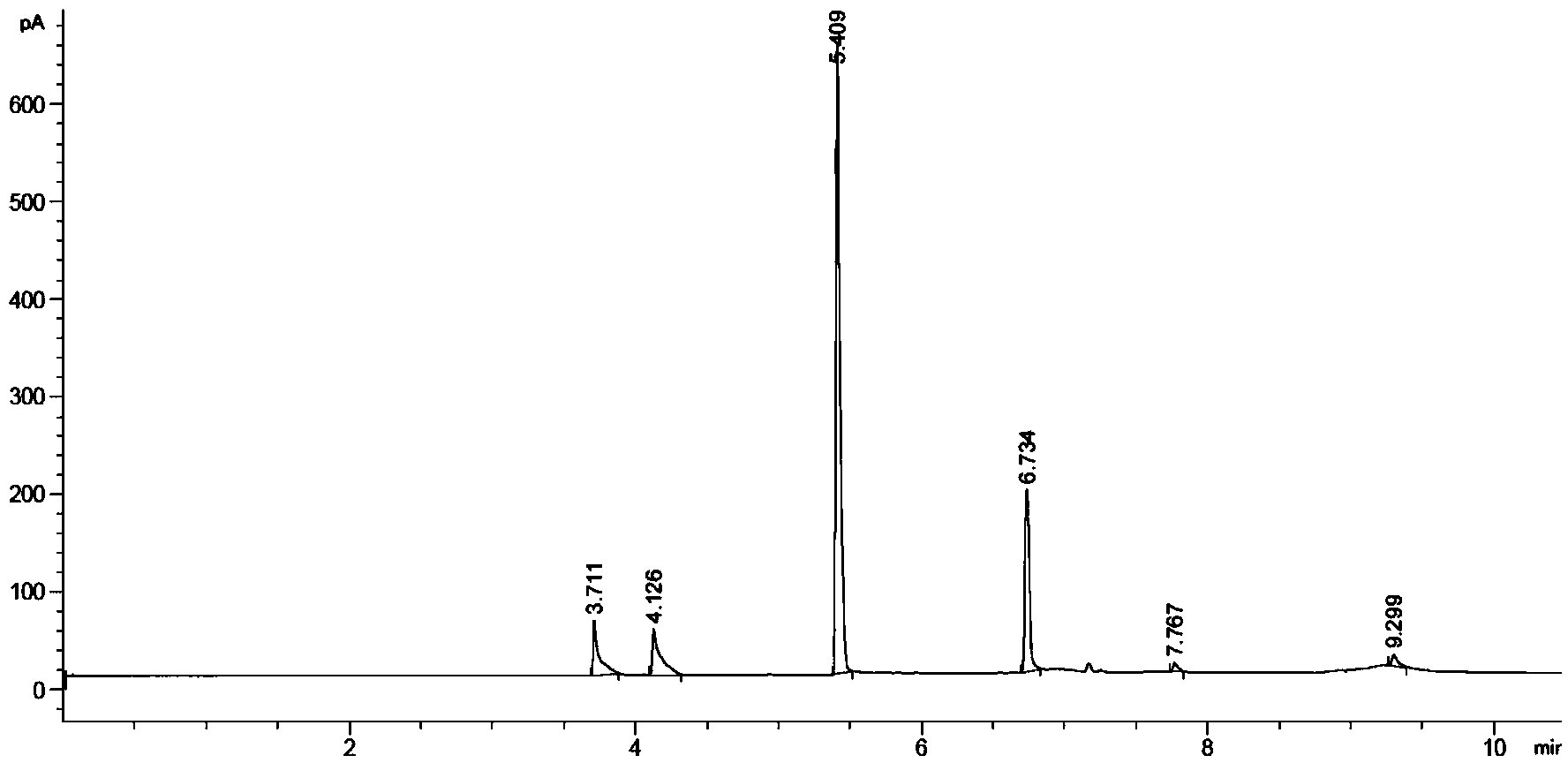

[0049] Fusobacterium acetobutylicum (C. acetobutylicum) B3 (pIMP1-ALDC) and B3 (pIMP1-BSU36000) were cultured statically at 37°C for 12 hours in P2 seed medium (without adding agar, and other components were the same as P2 plate medium). They were inoculated into the fermentation medium at an inoculum size of 10% (v / v). The formula of the fermentation medium is as follows: K 2 HPO 4 0.5g / L;KH 2 PO 4 0.5g / L;CH 3 COONH 4 2.2g / L; MgSO4 ·7H 2 O0.2g / L;MnSO 4 ·H 2 O0.01g / L; NaCl0.01g / L; FeSO 4 ·7H 2 O0.01g / L; p-aminobenzoic acid 1mg / L; thiamine 1mg / L; biotin 0.01mg / L. Anaerobic fermentation at 37°C for 60h. The components of the fermentation broth were detected by gas chromatography, and the detection conditions of gas chromatography were as follows: flame ion detector (FID), Agilent HP-INNOWAX19091N-236 capillary column (60m×0.25mm×0.25um), N2 as carrier gas, flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com