Tapering area micropore structure based single mode glass optical fiber liquid refractive index sensor

A technology of liquid refractive index and glass optical fiber, which is applied in the measurement of phase influence characteristics, etc., can solve the problems that limit the practical application of tapered optical fiber sensor to the measurement sensitivity of liquid refractive index, and the optical fiber is easy to break, so as to improve the measurement sensitivity, enhance the mechanical strength, The effect of high measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

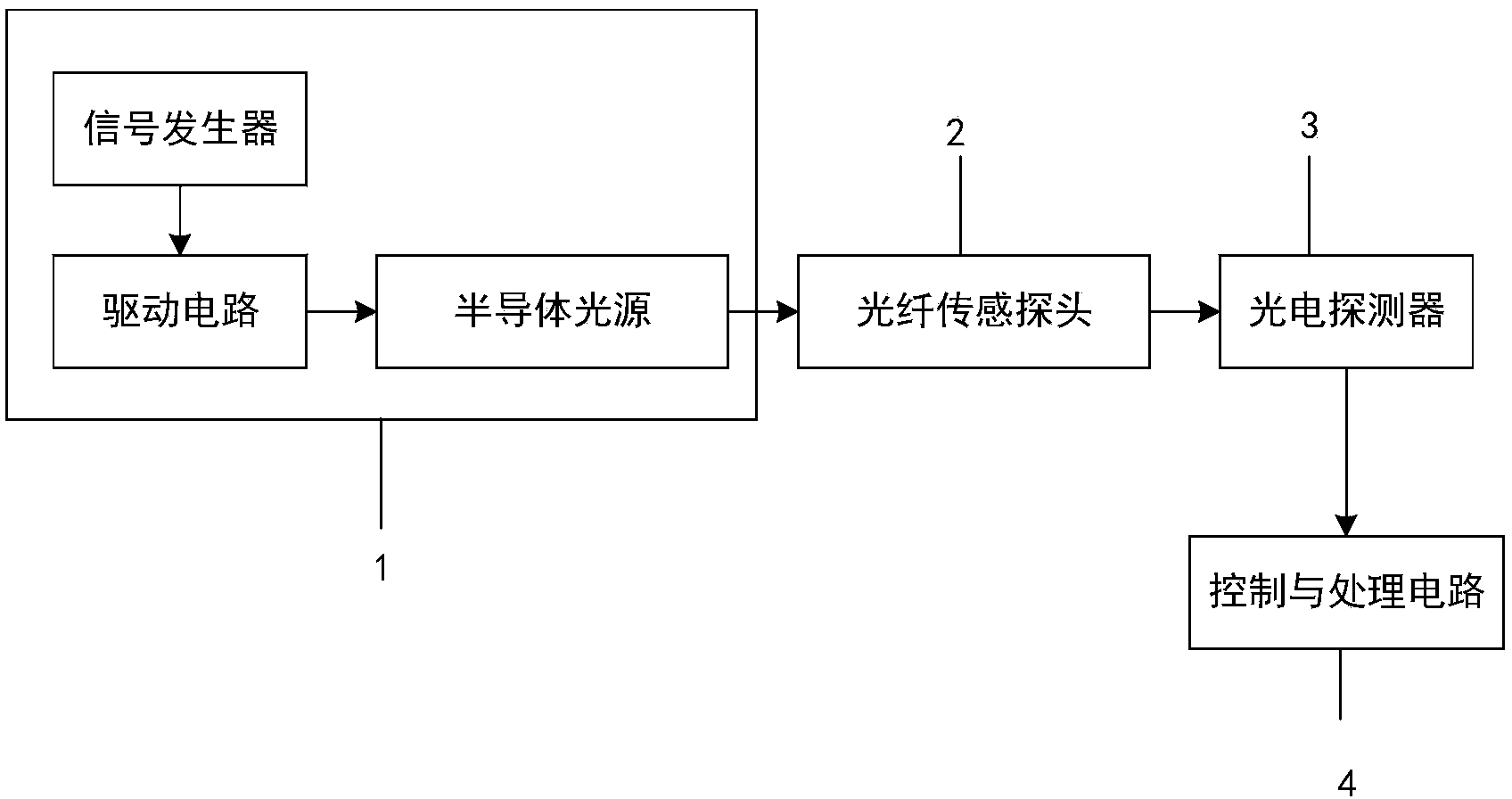

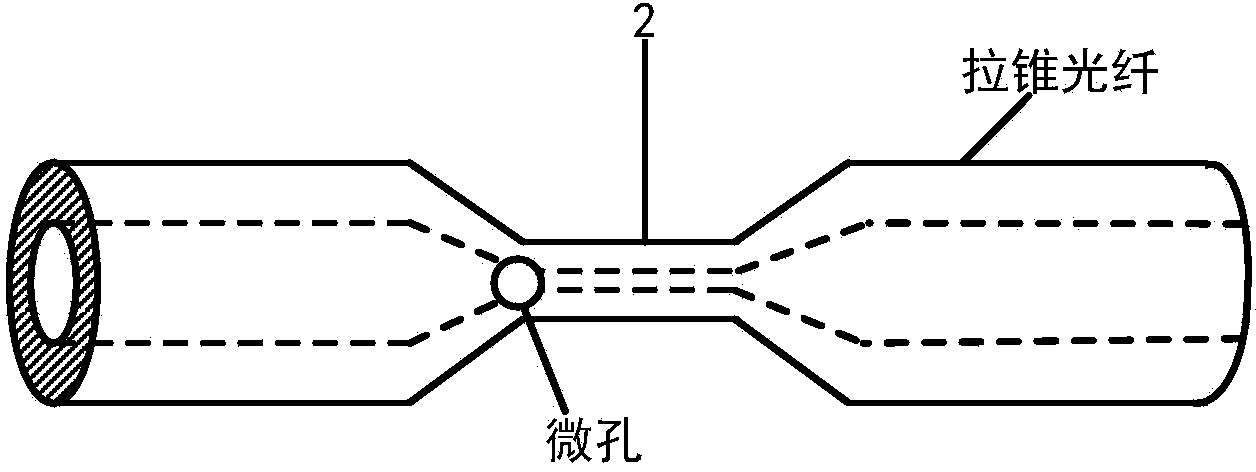

[0030] refer to figure 1 , the structure of the present invention's tapered microhole single-mode glass fiber optic liquid refractive index sensor includes a light source module 1, a tapered single-mode glass fiber sensor probe 2 with microholes, a photodetector 3, and a control and processing circuit 4. The input end of the tapered single-mode optical fiber sensing probe 2 with a microhole structure is connected to the light source module 1 with a pigtail through a single-mode glass optical fiber, and the output end of the tapered single-mode optical fiber sensing probe 2 with a microhole is connected through a single-mode optical fiber. The molded glass fiber is connected to the input end of the photodetector 3 with a pigtail, and the output end of the photodetector 3 is connected to the input end of the control and processing circuit 4 .

[0031] The light source module 1 is composed of a C-band semiconductor light source, a signal generator and a driving circuit, and the ...

Embodiment 2

[0034] Embodiment 2 The mode of operation of the device of the present invention

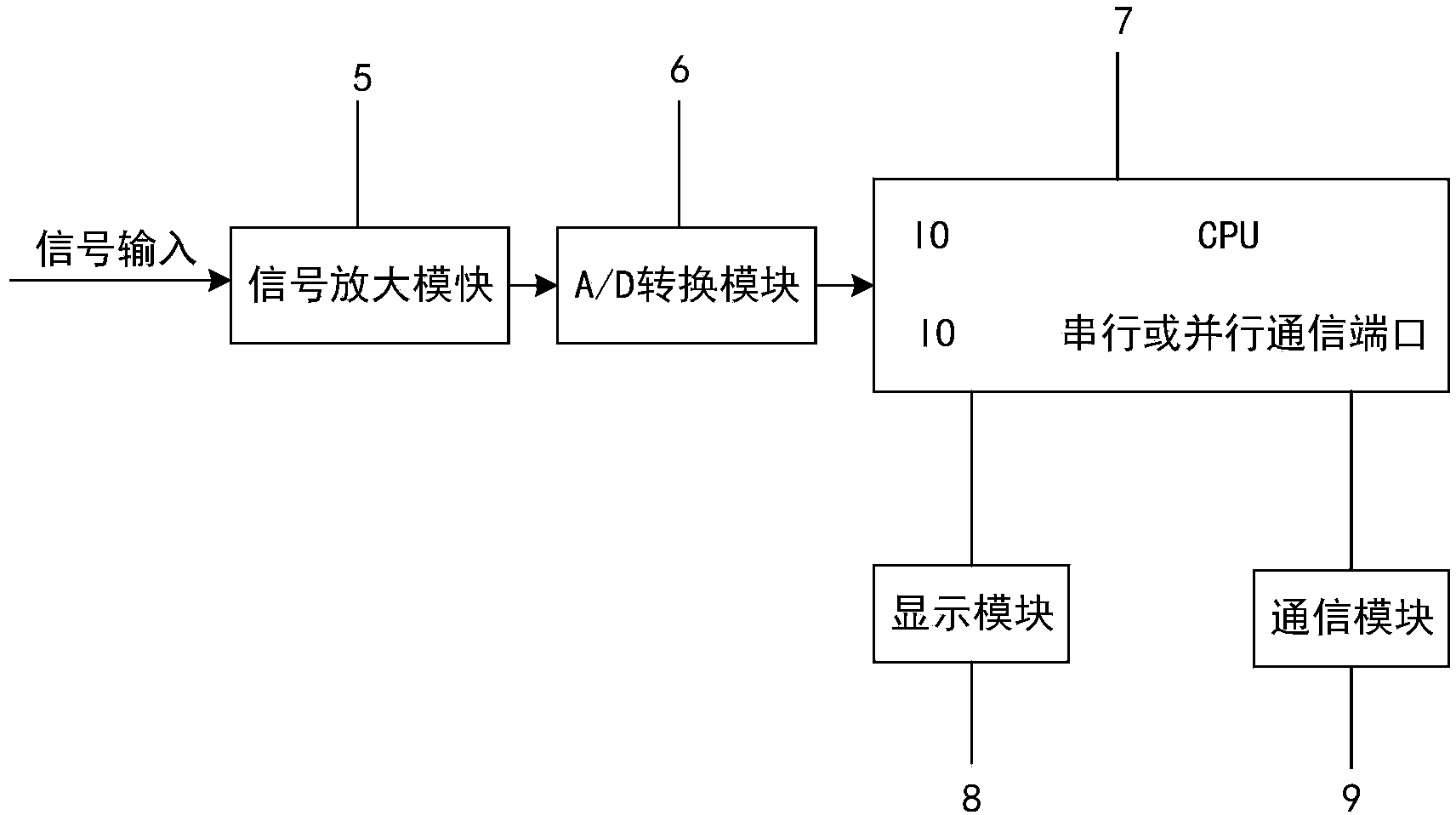

[0035] The radiated light of the light source after internal modulation enters the optical fiber sensing probe 2 and the photodetector 3 through the pigtail, and the optical power received by the photodetector 3 is related to the refractive index of the medium around the optical fiber probe. When the tapered region of the optical fiber sensing probe 2 is immersed in the liquid to be measured, if the refractive index of the liquid to be measured is large, the power loss in the fiber optic probe will increase; if the refractive index of the liquid to be measured becomes small, the power loss in the fiber optic probe The loss will be reduced. That is to say, the optical power detected by the photodetector 3 changes with the change of the refractive index of the liquid to be measured. The electrical signal obtained after photoelectric conversion by the photodetector 3 is amplified by the signal amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com