A surface treatment method that can control the carrier concentration of carbon-based semiconductor devices

A carrier concentration and surface treatment technology, applied in the field of nanoelectronics, can solve the problems of large structural damage of carbon materials and decreased carrier mobility of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

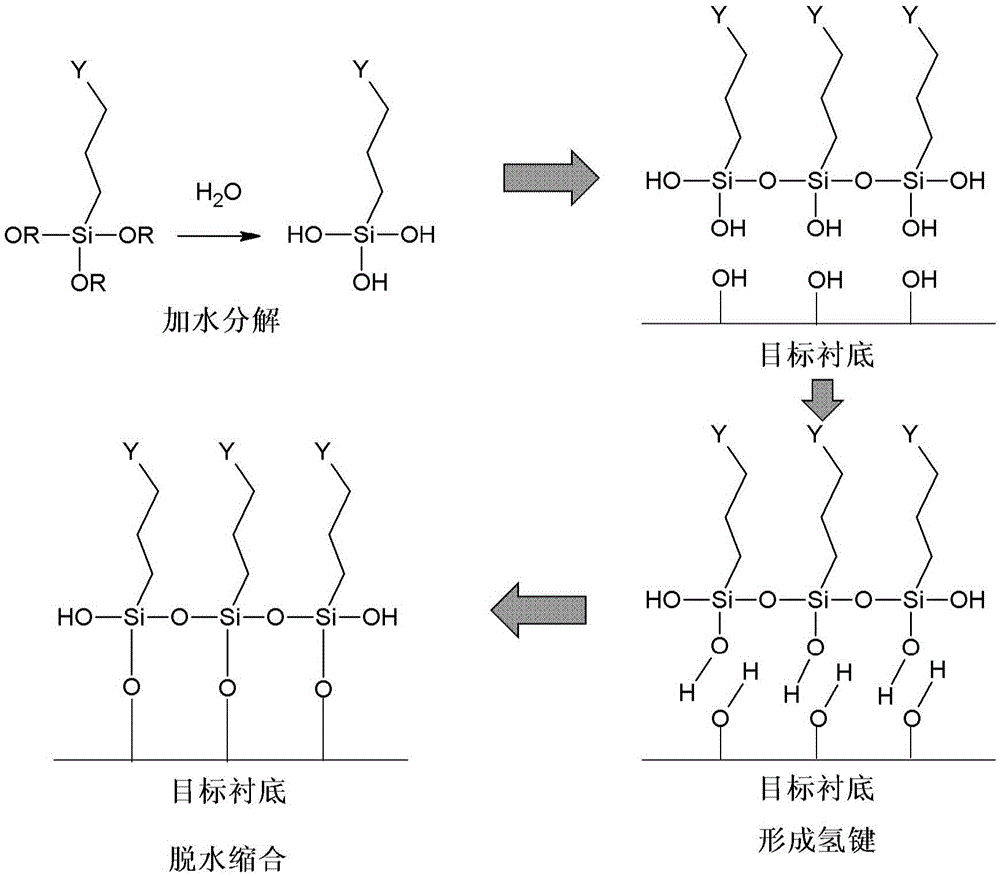

Method used

Image

Examples

Embodiment 1

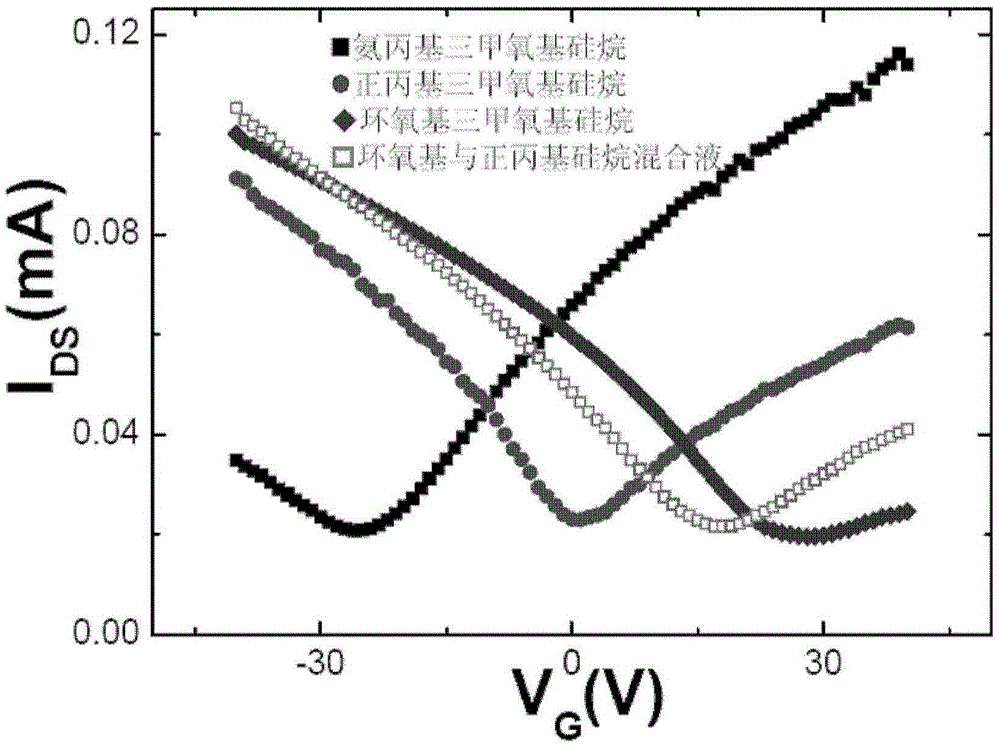

[0034] Embodiment 1: use CVD to grow graphene material, on the silicon dioxide / silicon substrate after n-propyltrimethoxysilane is processed film formation, realize graphene field effect transistor.

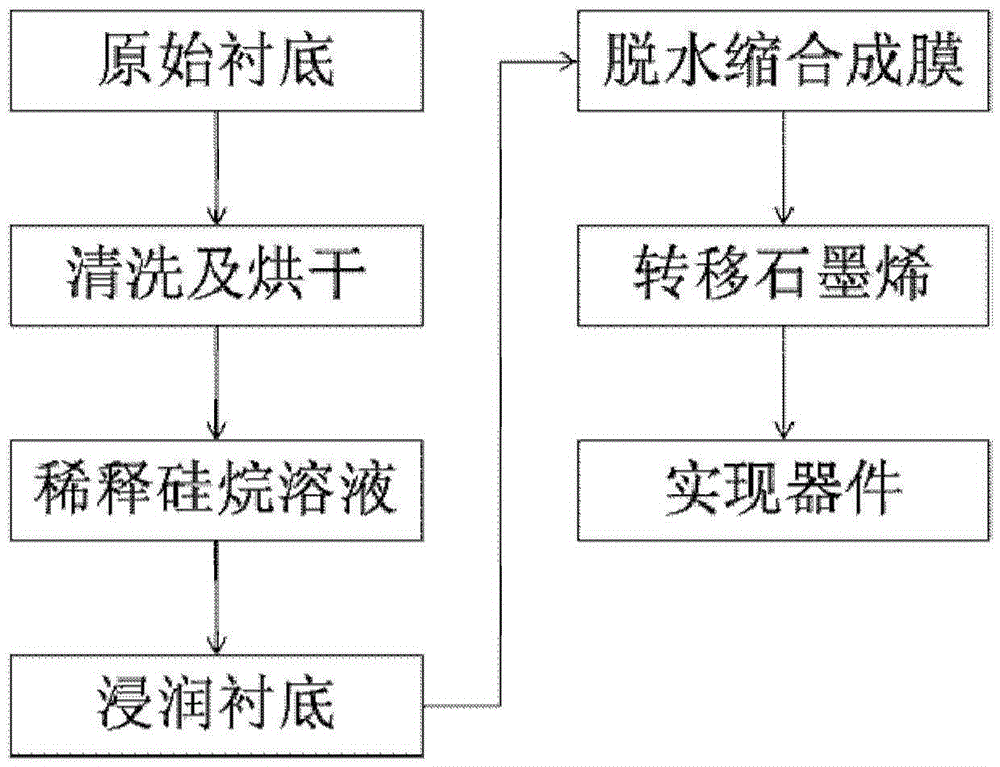

[0035] figure 2 Use silane coupling agent to carry out the flowchart of surface treatment to substrate for the embodiment of the present invention, comprise the following steps:

[0036] Step 1: After diluting the silane coupling agent with a solvent, immerse the substrate in the diluted solution. Before immersing, the substrate material needs to be cleaned and baked and dried;

[0037] In this embodiment, the silane coupling agent-n-propyltrimethoxysilane dilution is prepared, and n-propyltrimethoxysilane (purchased from China Pharmaceutical Group Chemical Reagent Beijing Co., Ltd.) and absolute ethanol solution are mixed in volume ratio 1:20-1:400 for dilution, shake well after dilution, immerse the substrate in the silane dilution solution for 1-20 minutes; then put the clea...

Embodiment 2

[0042] Embodiment 2: use CVD to grow graphene material, on the silicon dioxide / silicon substrate after processing film formation through aminopropyltrimethoxysilane, realize graphene field effect transistor.

[0043] The specific steps are similar to Example 1, but in step 1, the dilute solution is prepared with aminopropyltrimethoxysilane and absolute ethanol at a ratio of 1:20-1:400, and the substrate is immersed in the silane diluent for 1-20 minutes . After step 3, measure the thickness of the aminopropyltrimethoxysilane organic film layer to be 1nm-20nm.

Embodiment 3

[0044] Embodiment 3: use CVD growth graphene material, on the silicon dioxide / silicon substrate after (3-oxiranyl methoxy propyl) trimethoxysilane process film formation, realize graphene field effect transistor .

[0045] The specific steps are similar to Example 1, but in step 1, use (3-oxiranylmethoxypropyl) trimethoxysilane and isopropanol to dilute with a volume ratio of 1:20-1:400, and the substrate Wetting deposition time is 1-20 minutes. After step 3, measure the thickness of the (3-oxiranylmethoxypropyl)trimethoxysilane organic film layer to be 1nm-20nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com