Erbium-doped fiber laser based on 3*3 micro optical fiber coupler and manufacturing method thereof

An erbium-doped fiber and coupler technology, which is applied in the field of optoelectronics, can solve the problems of complex micromachining process and difficult matching of fiber systems, and achieve the effects of enhancing evanescent field, simple optical path, and excellent temperature and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

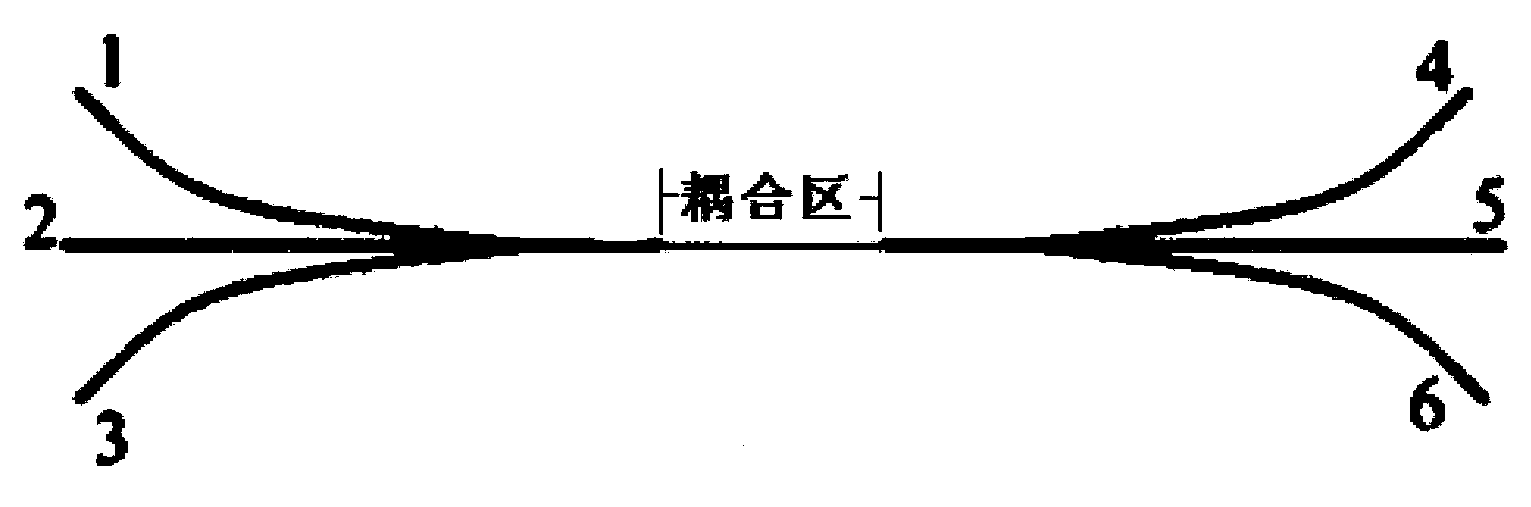

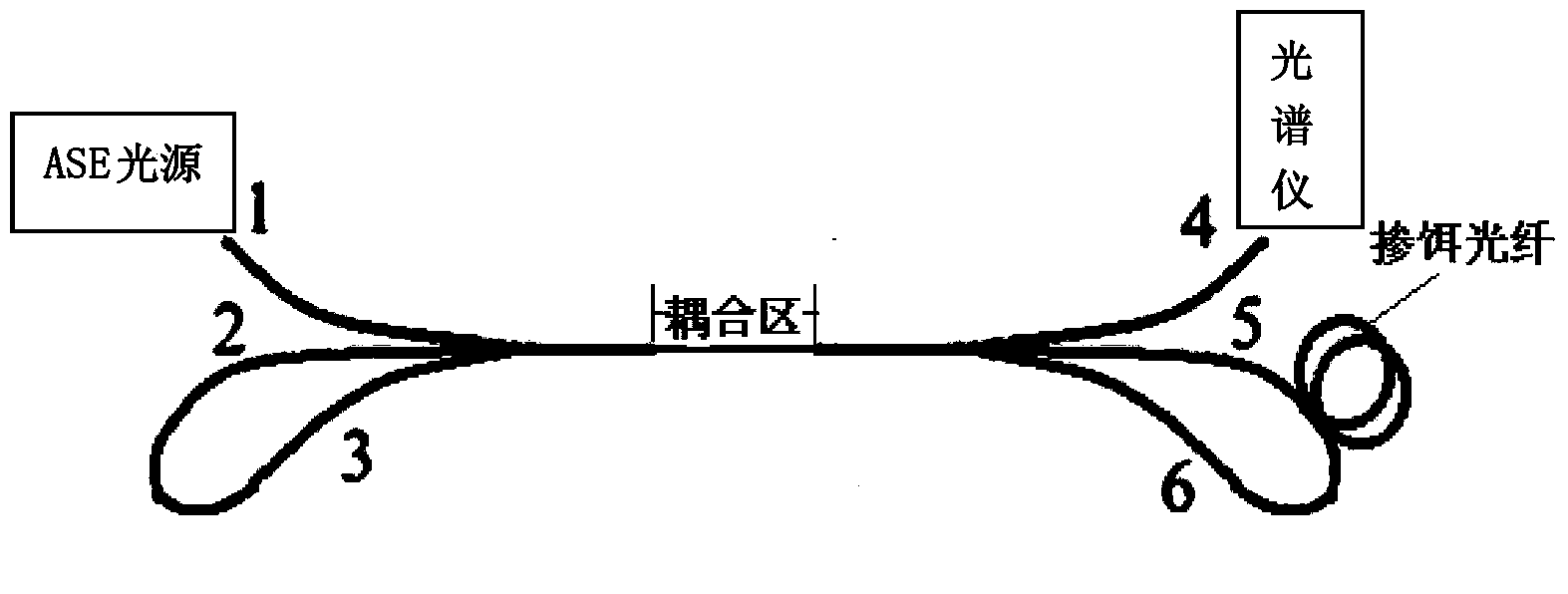

[0019] The erbium-doped fiber laser based on the 3×3 micro-fiber coupler of the present invention includes a Sagnac ring formed by fusion splicing fibers at both ends, and a section of 90cm-long erbium-doped fiber. Such as figure 2 As shown, the pump light is input into the device through port 1, and when the pump light passes through the coupling region, due to the coupling effect between the three optical fibers, the pump light will be output through ports 4, 5, and 6 respectively. When splicing ports 5 and 6, a section of erbium-doped optical fiber with a length of 90 cm is inserted. The gain of this erbium-doped optical fiber can generate laser light while requiring less pumping light. The pumping light from ports 5 and 6 pumps the erbium-doped fiber to make it in the state of population inversion, and amplifies the spontaneous emission of the erbium-doped fiber to generate light in the 1525nm to 1565nm band (ASE light). The generated ASE light is coupled into ports 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com