Method and system for recycling non-clean water source by utilizing osmotic energy

A penetrating energy and clean technology, applied in the field of separation, can solve the problem of high processing cost, and achieve the effects of reducing usage, improving economic benefits and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

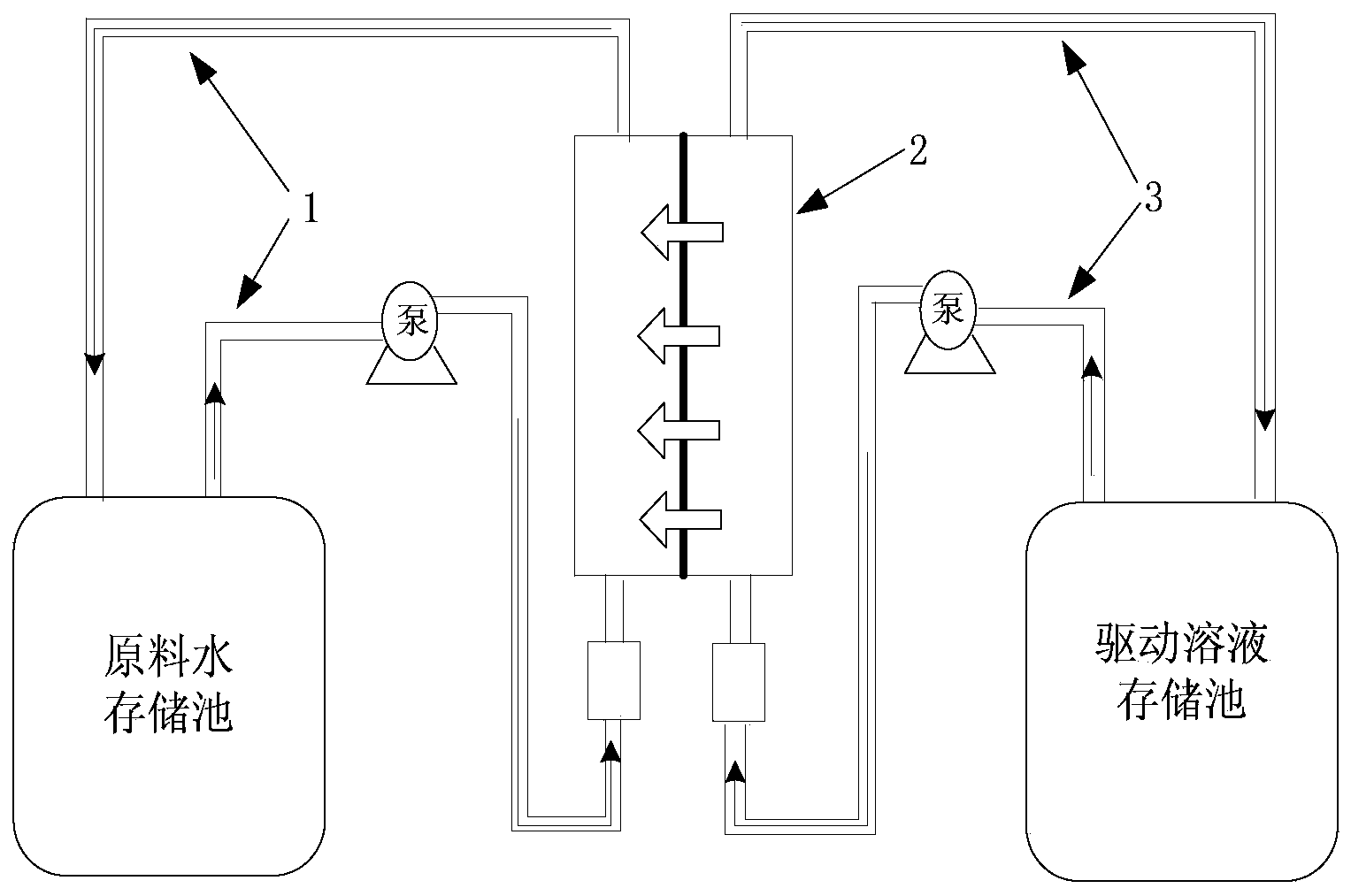

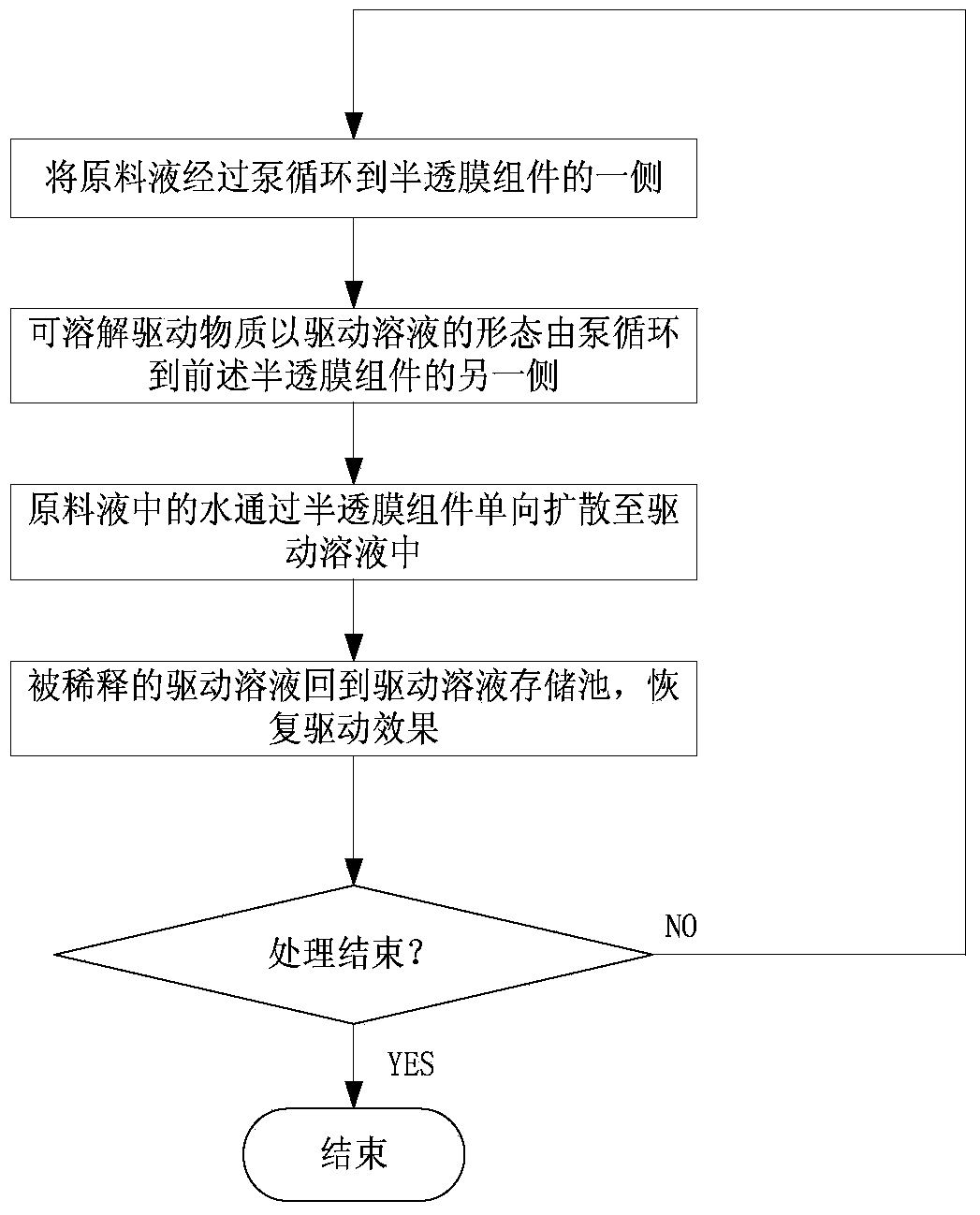

Method used

Image

Examples

example 1

[0055] Example 1: Coupling of sodium chloride dissolution in chlor-alkali plant and municipal sewage

[0056] Chlor-alkali plants have a large amount of sodium chloride salt to be refined every year. The first step of refining is to use a large amount of water to dissolve the solid salt, and then count it into the next step of removing calcium, magnesium and sulfate ions. Dissolving solid salt requires nearly three times as much clean water. This example takes the dissolution of sodium chloride as an example to illustrate the characteristics and advantages of the present invention.

[0057] The effluent from the second-layer pool of the municipal sewage treatment plant is used as the raw material solution. The COD content of sewage is 150 mg / L, which does not meet the requirements of sodium chloride refining for dissolved water. Using osmotic dilution technology, municipal sewage is used as the raw material liquid, solid sodium chloride is used as the driving substance, and t...

example 2

[0060] Alkali plants have a large amount of sodium chloride salt to be refined every year. The first step of refining is to dissolve the solid salt with a large amount of water, which requires nearly three times as much clean water to dissolve the solid salt. Most of the sodium chloride salt in the alkali plant is obtained through the concentration of underground brine, and drying salt requires a lot of land resources, and it is a low-efficiency process. This example is to illustrate the characteristics and advantages of the present invention by taking the actual application of an alkali plant as an example.

[0061] Underground brine is used as the raw material solution, and its water quality index is shown in Table 1 below. The data in the table shows that the salt content of brine reaches 10.8%. Using conventional reverse osmosis or nanofiltration membrane technology, the operating pressure is very high, which is technically unfeasible. Therefore, in alkali plants, salt dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com