Filter material module capable of effectively removing phosphorus and sulfur in wastewater

A filter material and wastewater technology, which is applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of toxic and corrosive sulfur-containing wastewater, high chemical cost, and high operating cost. Achieve the effect of resource utilization, convenient addition and replacement, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

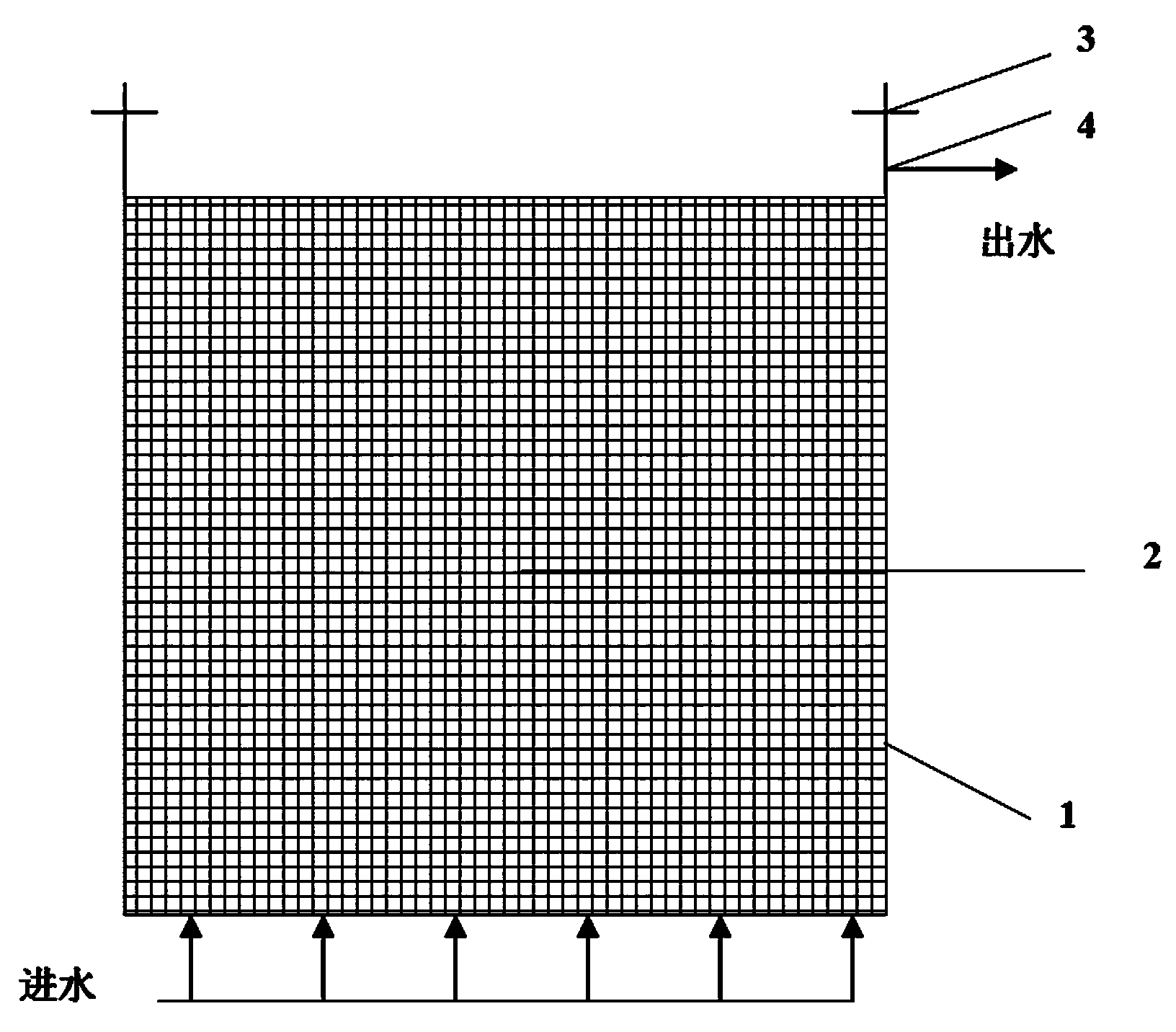

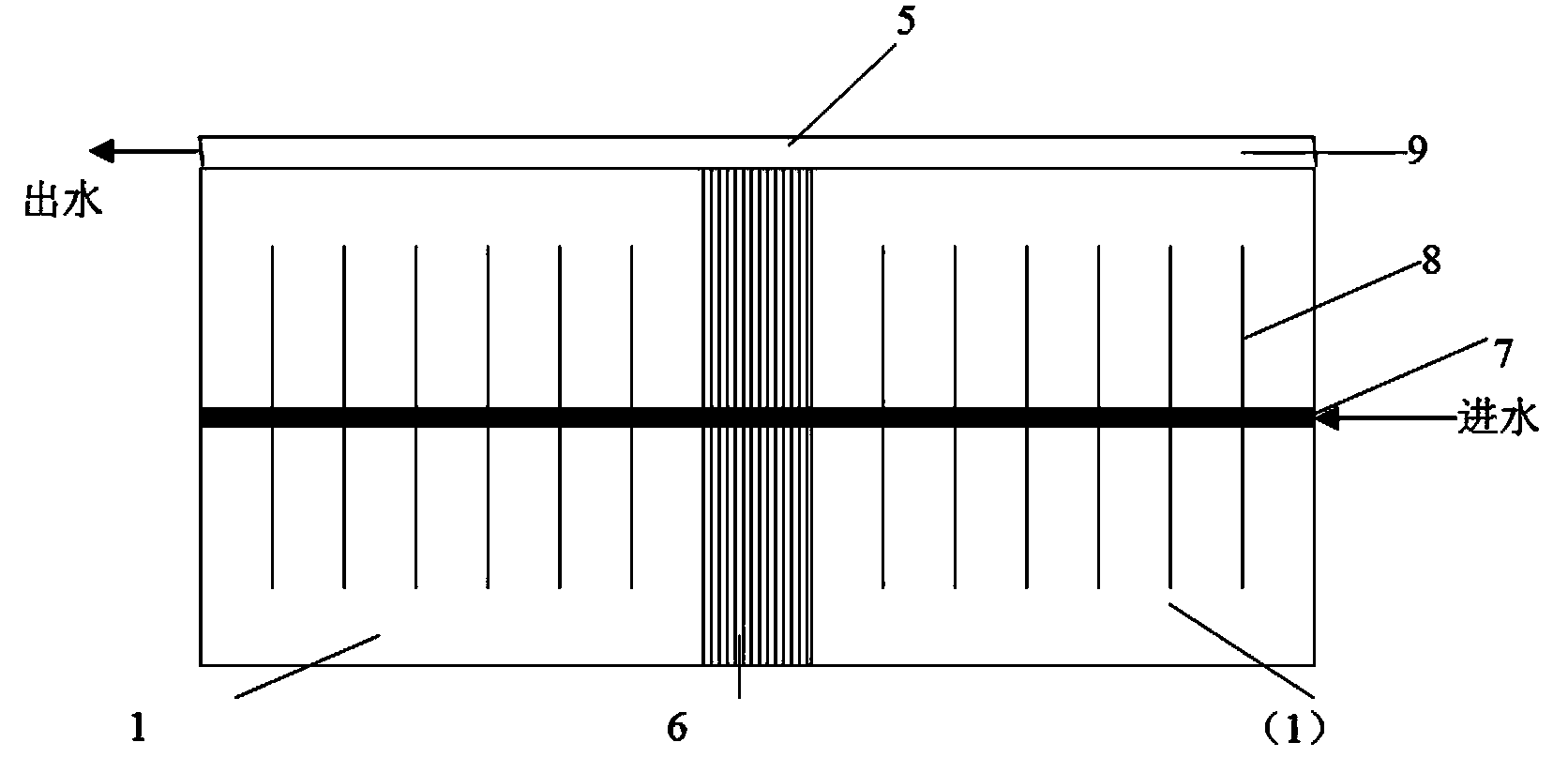

[0021] Take a factory that continuously discharges phosphating wastewater with a displacement of 1 t / h as an example, and the filter size is 1.05*1.05*1.2 m 3 , select 1*1*1 m 3 The processing module, the filling rate of the filter material is 50%, and the hydraulic retention time is 0.5h.

[0022] Such as figure 2 As shown, two processing modules 1 are set in the filter tank 5, one for use and the other for standby, and they are used alternately. Between the two processing modules, there is a middle channel 6 of cement structure with a width of 2 meters, which is used for setting up a triangle hanger when workers pass through and replace filter materials. The bottom of the filter tank 5 is provided with a main water inlet pipe 7 and a distribution pipe 8 (opening at the upper end), an overflow weir 9 is provided at a distance of 1.1 m from the bottom of the top of the filter tank, and an outlet pipeline is provided outside the tank body.

[0023] The waste water enters fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com