Purification method of trifluoromethanesulfonic anhydride

A technology of trifluoromethanesulfonic anhydride and a purification method, which is applied in the field of purification of trifluoromethanesulfonic anhydride, can solve the problems of low product purity and complicated process, and achieves the effects of high purification efficiency, simple operation and improved economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

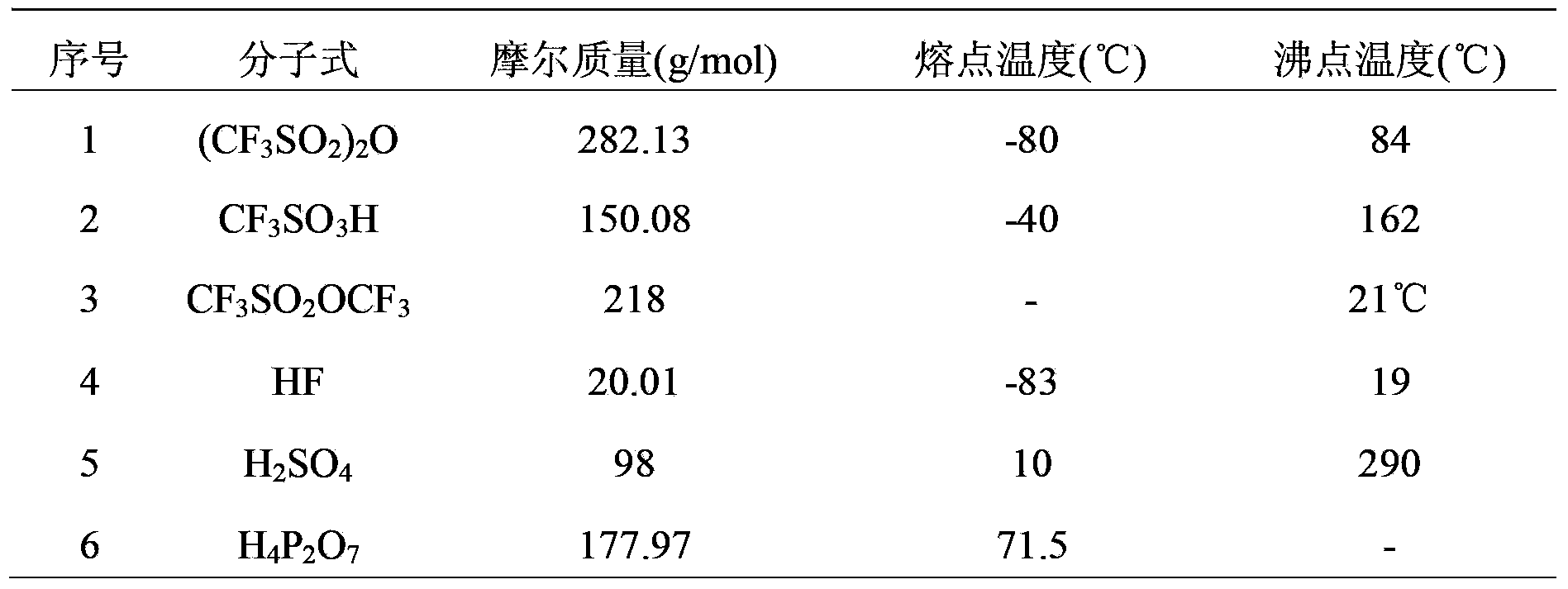

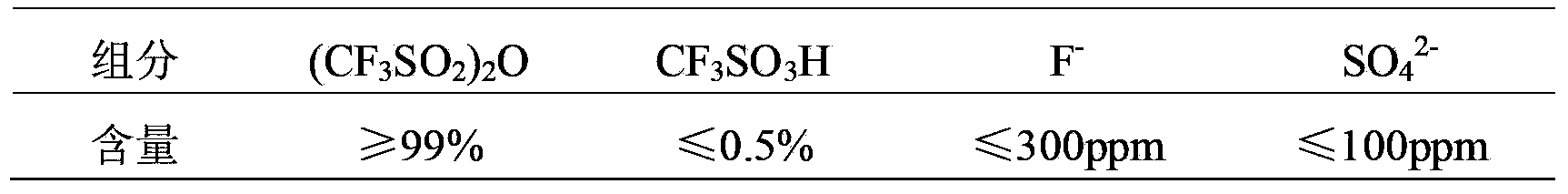

[0029] Raw materials: The crude product of trifluoromethanesulfonic anhydride is obtained by the reaction of trifluoromethanesulfonic acid and phosphorus pentoxide, and its main components are shown in Table 3.

[0030] Table 3 trifluoromethanesulfonic anhydride crude product composition list

[0031]

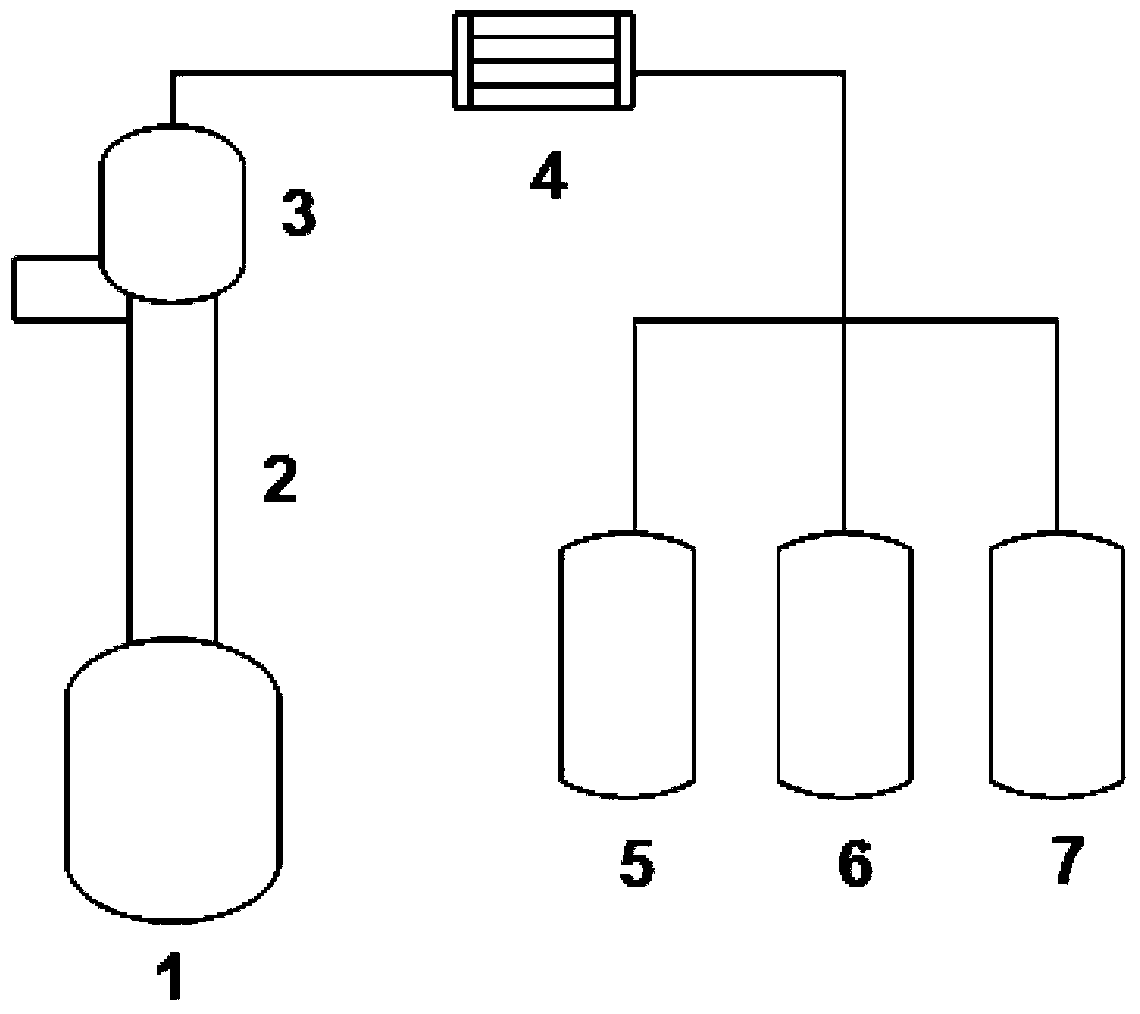

[0032] Rectification device: rectification kettle 1 is a 1000ml round-bottom flask, glass rectification tower 2 has an inner diameter of 25mm, and is equipped with 3mm×3mmθ mesh ring packing, and the number of trays is 10.

[0033] Rectification process: 1200g trifluoromethanesulfonic anhydride crude product (its composition is shown in Table 3) is joined in the round-bottomed flask, vacuumizes the rectification system, makes pressure be-0.025MPa, starts heating, and opens the cooling of reflux device 3 The water starts to reflux completely, and the total reflux time is 1h, so that the impurity component with a boiling point lower than that of trifluoromethanesulfonic anhydr...

Embodiment 2

[0040] Raw material: with embodiment 1

[0041]Rectification device: rectification kettle with 1000ml round bottom flask, glass rectification tower 2 with inner diameter of 25mm, 3mm×3mmθ ring packing inside, 30 trays.

[0042] Rectification process: 1200g trifluoromethanesulfonic anhydride crude product (its composition is shown in Table 3) is joined in the round bottom flask, vacuumizes the rectification system, makes pressure be-0.065MPa, starts heating, and opens the cooling of reflux device 3 The water starts to fully reflux, and the total reflux time is 5 hours, so that the impurity component with a boiling point lower than that of trifluoromethanesulfonic anhydride is enriched at the top of the rectifying tower 2 . Then, when the rectifying still 1 temperature is 50 DEG C, the rectifying tower 2 tower top temperature is 40 DEG C, collect the front fraction with the reflux ratio of 10, and recycle in the front fraction receiving tank 5 through the condensate in the conde...

Embodiment 3

[0048] Raw material: with embodiment 1

[0049] Rectification device: rectification kettle with 1000ml round bottom flask, glass rectification tower 2 with inner diameter of 25mm, inner packing of 3mm×3mmθ mesh ring, 20 trays.

[0050] Rectification process: 1200g trifluoromethanesulfonic anhydride crude product (its composition is shown in Table 3) is joined in the round-bottomed flask, vacuumizes the rectification system, makes pressure be-0.05MPa, starts heating, and opens the cooling of reflux device 3 The water starts to reflux completely, and the total reflux time is 3 hours, so that the impurity component with a boiling point lower than that of trifluoromethanesulfonic anhydride is enriched at the top of the rectifying tower 2 . Then, when the temperature of the rectifying tank 1 is 55°C and the temperature of the top of the rectifying tower 2 is 50°C, the front fraction is collected with a reflux ratio of 12, and the condensate in the condenser 4 is recycled to the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com