Method for producing liquid fuel by performing fast pyrolysis on solid organic matters

A technology for solid organic matter and liquid fuel, which is applied in the preparation of biofuel and liquid hydrocarbon mixture, direct heating and dry distillation, etc. It can solve the problems of solid product cooling engineering difficulties, affecting process economy, and high ash content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

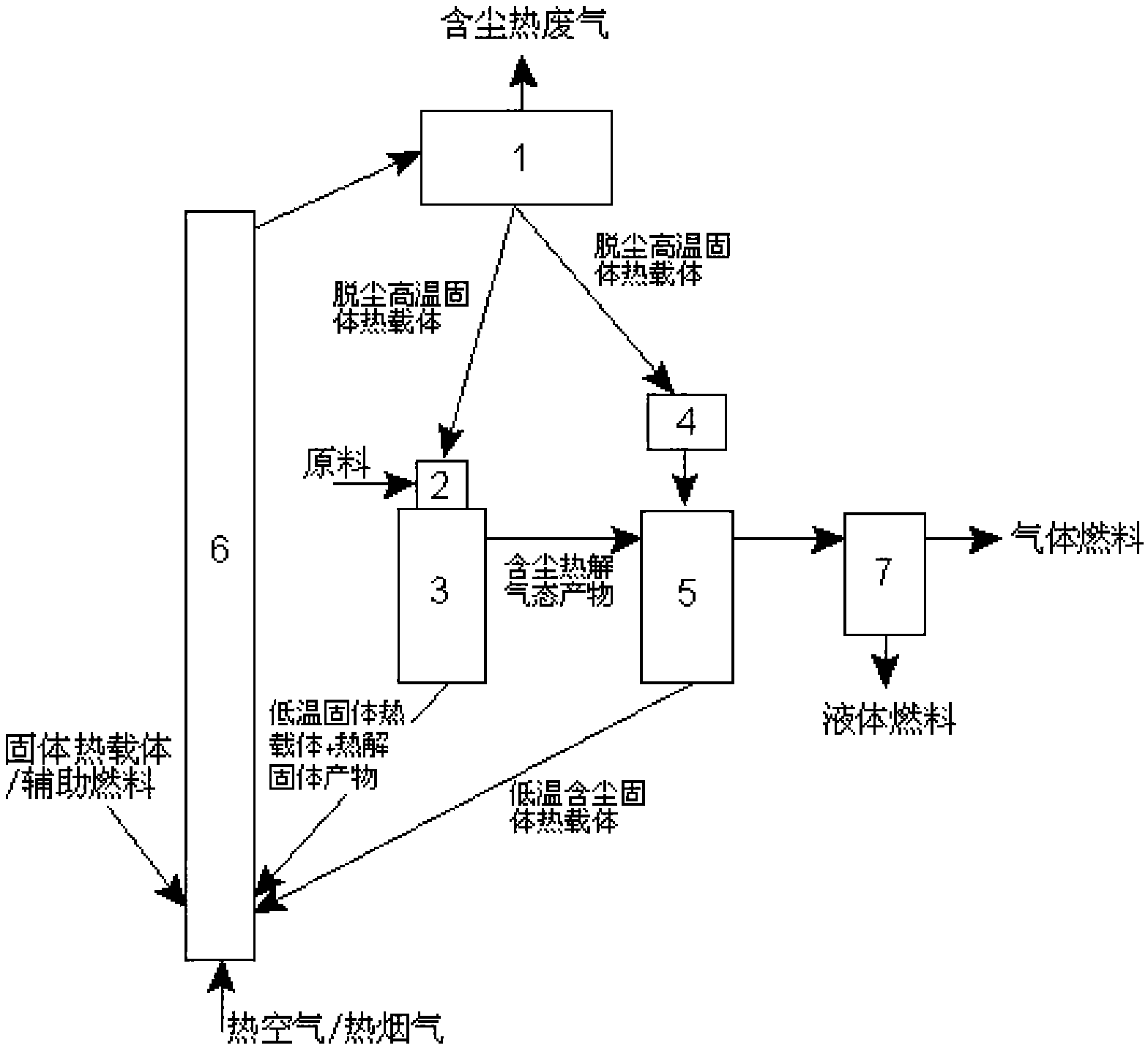

[0065] The rapid co-pyrolysis of white pine sawdust and lignite is carried out in the experimental device with a raw material handling capacity of 1kg / h. The operating principle of the experimental device is the same as figure 1 . The air-dried base moisture, air-dried base volatile matter, air-dried base ash, particle size of the first raw material white pine sawdust and the second raw material lignite are 5.0wt%, 77.7wt%, 0.3wt%, less than 3mm and 27.9wt%, 35.1 wt%, 7.9wt%, less than 2mm. Before the experiment, the raw materials were dried in an oven at 105-110°C for 3 hours. Olivine particles with a particle size of 0.2-1.2mm are used as the circulating solid heat carrier.

[0066] The dried white pine sawdust and lignite are quantitatively fed into the secondary screw feeder from their respective raw material storage tanks via the corresponding primary screw feeder, and the feeding rate is the same as 250g / h. The mixture of white pine sawdust and lignite is quickly conv...

Embodiment 2

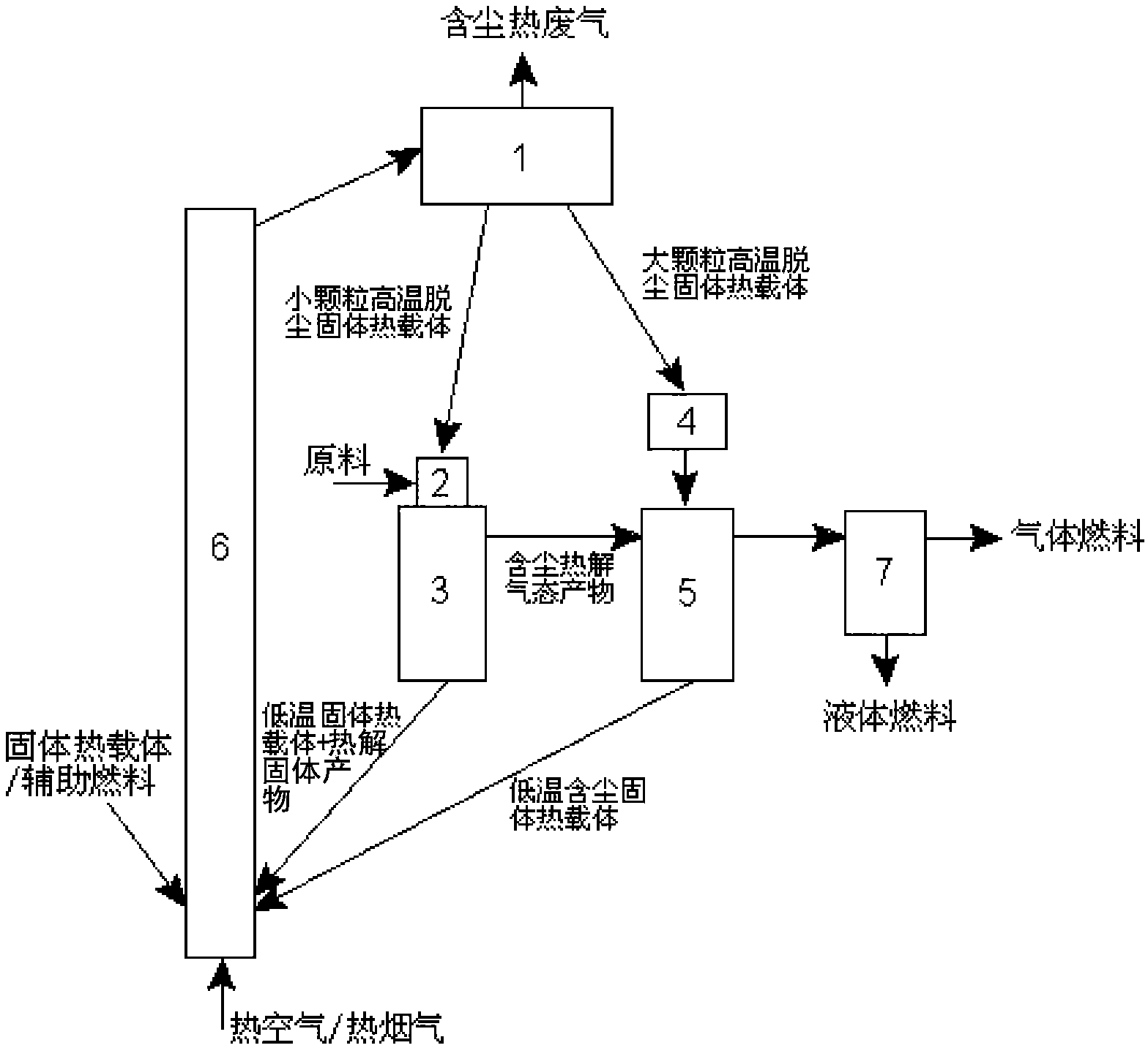

[0075] The rapid co-pyrolysis of white pine sawdust and lignite was carried out in the experimental device with a raw material handling capacity of 1kg / h. The solid heat carrier dust collector 1 in the experimental device was replaced by the solid heat carrier classifying dust collector 1 with particle size classification function, and the others were the same Example 1.

[0076] Solid heat carrier classifying dust collector 1 adopts Figure 5 The structure shown is composed of an inner cylinder 11 and an outer cylinder 12. The bottoms of the inner and outer cylinders are conical, and there is a solid heat carrier outlet at the bottom, which leads to the mixing unit 2 of the moving bed pyrolysis reactor and the moving particle layer filter respectively. Dust collector 5. The top of the inner cylinder 11 is open, and the height is about 1 / 3-2 / 3 of the height of the outer cylinder 12 . The center of the top of the solid heat carrier classifying dust collector is provided with ...

Embodiment 3

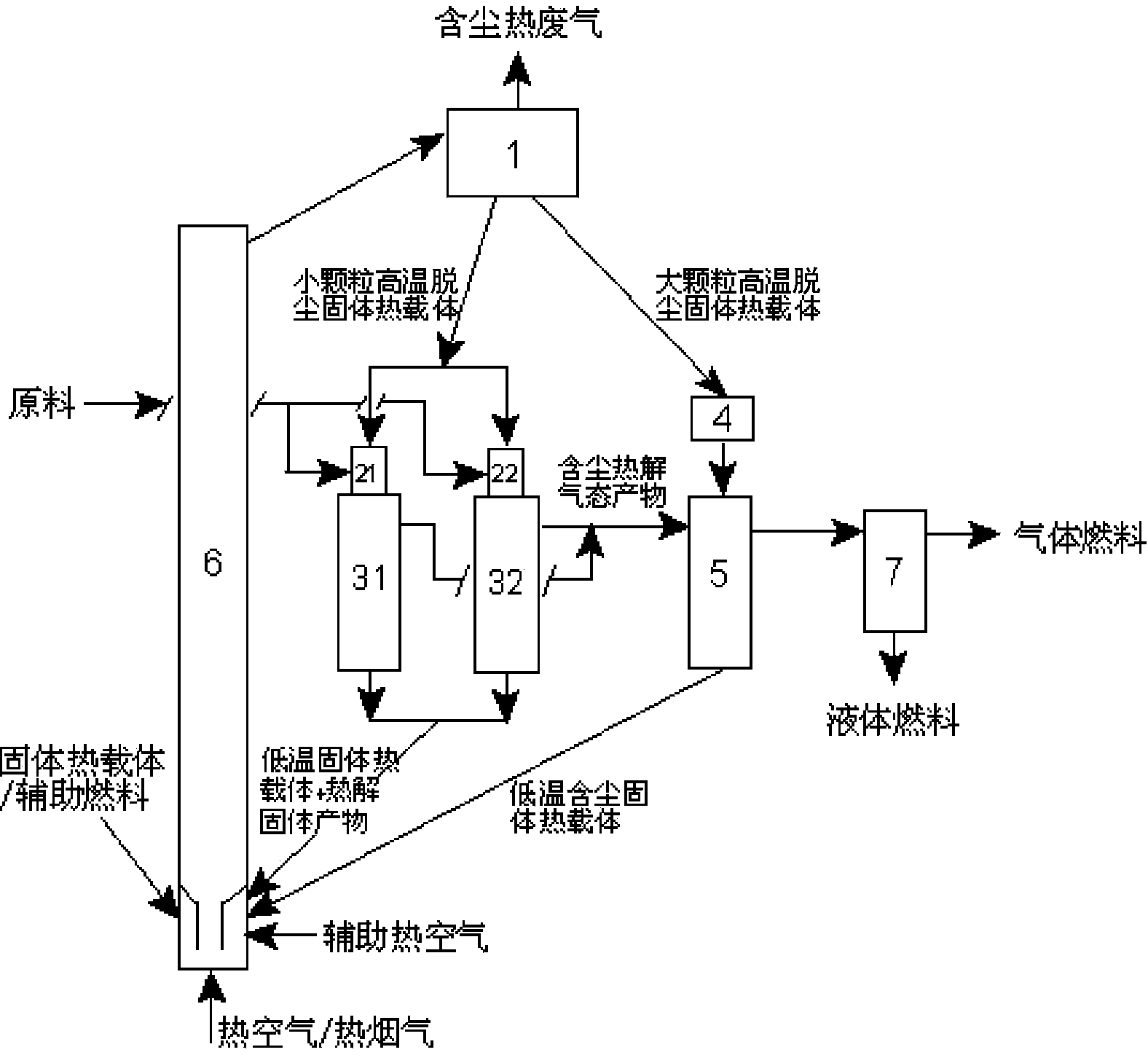

[0081] The rapid pyrolysis of young bituminous coal is carried out in an experimental device with a raw material handling capacity of 1kg / h. The operating procedure of the experimental device is shown in Figure 4 . The air-dry basis moisture, air-dry basis volatile matter, air-dry basis ash content and particle size of raw bituminous coal are 10.3wt%, 28.5wt%, 4.1wt% and less than 2mm, respectively. Before the experiment, the raw materials were dried in an oven at 105-110°C for 3 hours. The solid product produced by the pyrolysis of raw coal is used as the circulating solid heat carrier.

[0082] The feed rate of raw coal after drying was 350 g / h. The flow rate of the circulating solid product entering the pyrolysis reactor from the inner cylinder 11 of the solid heat carrier classifying dust collector is controlled at 1.2kg / h.

[0083] The flow rate of the circulating solid product entering the mobile particle layer filter dust collector 5 from the outer cylinder 12 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com