Manufacture method of 50CrVA alloy structural steel type hot rolled round steel bar

A technology of alloy structural steel and a manufacturing method, which is applied in the manufacturing field of 50CrVA alloy structural hot-rolled round steel bars, can solve the problems of large consumption of electricity-consuming graphite electrodes, unfavorable energy conservation and environmental protection, and high production cost, and achieves low production cost, Low power consumption and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

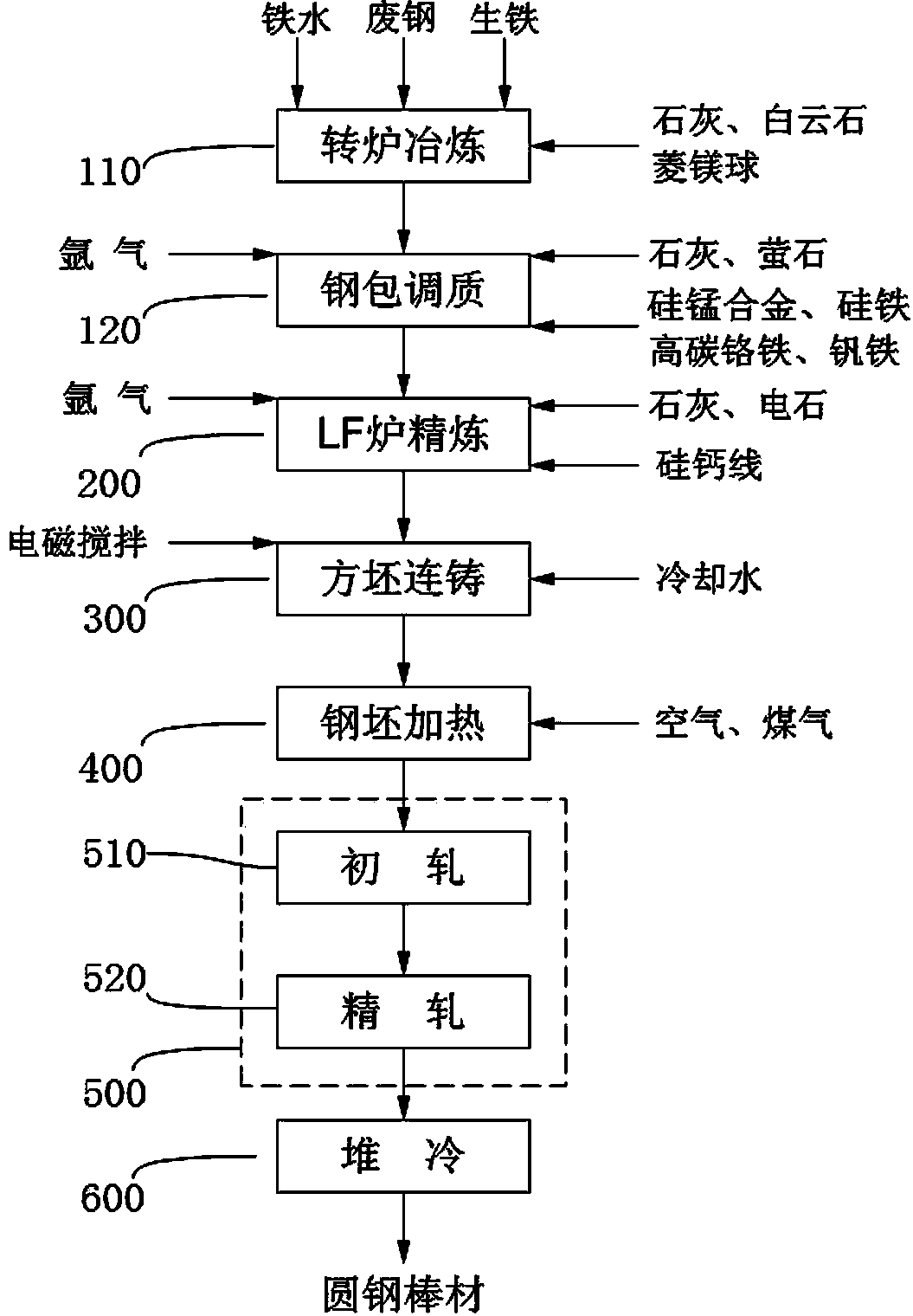

Method used

Image

Examples

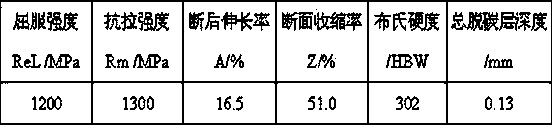

Embodiment 1

[0048] A. Molten steel smelting: the chemical composition C5.0wt%, Si0.65wt%, Mn 0.50wt%, P 0.150wt%, S0.012wt%, the rest is Fe and unavoidable impurities of molten iron, chemical composition C00.40wt%, Si0.40wt%, Mn0.70wt%, P0.040wt%, S0.040wt%, the rest is Fe and unavoidable impurity steel scrap and chemical components C4.0wt%, Si0. 65 wt%, Mn 0.60 wt%, P 0.090wt%, S0.040wt%, the rest is Fe and unavoidable impurities of pig iron into the converter, the conventional top-bottom compound blowing, adding lime, white cloud Stone and magnesite ball slagging, the carbon content at the end point is controlled to 0.12wt%, and the tapping temperature is 1659°C; lime and fluorite are added to the bottom of the ladle before tapping, and the amount of lime added is: 5.0kg / t 钢 , the amount of fluorite added: 0.4kg / t 钢 ;The process of slag washing and full bottom argon blowing is adopted when tapping the steel, and the flow rate of argon gas is controlled at 30NL / min. When the amount of m...

Embodiment 2

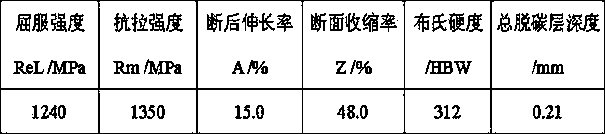

[0058] A. Molten steel smelting: It is molten iron with chemical components C 4.5wt%, Si 0.50 wt%, Mn 0.425 wt%, P 0.115wt%, S0.008wt%, and the rest is Fe and inevitable impurities. C0.325wt%, Si0.30wt%, Mn0.55wt%, P 0.033wt%, S 0.030wt%, the rest is Fe and unavoidable impurity steel scrap and chemical components C3.75wt%, Si0.525 wt%, Mn 0.45 wt%, P 0.080wt%, S 0.030wt%, the rest is Fe and unavoidable impurities of pig iron into the converter, the conventional top-bottom composite blowing, adding lime, dolomite in conventional amounts , Magnesite ball slagging, the carbon content at the end point is controlled to 0.10wt%, and the tapping temperature is 1652°C; before tapping, lime and fluorite are added to the bottom of the ladle, and the amount of lime added is: 5.0kg / t 钢 , the amount of fluorite added: 0.4kg / t 钢 ; When tapping, adopt slag washing and full bottom argon blowing process, argon flow control 40NL / min, when the amount of molten steel in the ladle is greater than...

Embodiment 3

[0068] A. Molten steel smelting: the chemical composition C 4.0wt%, Si 0.35wt%, Mn 0.25wt%, P 0.080wt%, S 0.005wt%, the rest is Fe and unavoidable impurities of molten iron, chemical composition C0.25wt%, Si0.20wt%, Mn0.40wt%, P0.025wt%, S0.020wt%, the rest is Fe and inevitable impurity steel scrap and chemical composition C3.5wt%, Si0.40 wt% %, Mn 0.30 wt%, P 0.070wt%, S 0.020wt%, the rest is Fe and unavoidable impurities of pig iron into the converter, the conventional top-bottom compound blowing, adding lime, dolomite, Magnesite ball slagging, the carbon content at the end point is controlled to 0.13wt%, and the tapping temperature is 1648°C; lime and fluorite are added to the bottom of the ladle before tapping, and the amount of lime added is: 5.0kg / t 钢 , the amount of fluorite added: 0.4kg / t 钢 ; When tapping, adopt slag washing and full bottom argon blowing process, argon flow control is 50NL / min, when the amount of molten steel in the ladle is greater than 1 / 4, add the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com