A kind of surface treatment method of stainless steel

A surface treatment, stainless steel technology, applied in surface reaction electrolytic coating, ion implantation plating, anodizing and other directions, can solve the problem of single color of stainless steel surface treatment, and achieve the effect of rich appearance color and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

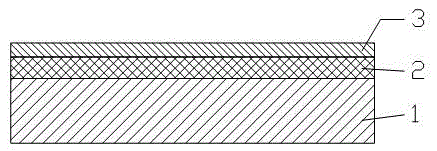

Image

Examples

Embodiment 1

[0041] Pre-plating treatment of stainless steel substrates: conventional stainless steel metal surface pretreatment methods;

[0042] Electroplated aluminum film: the electroplating solution contains AlCl 3 The concentration is 150g / L, the HCl concentration is controlled at 0.5mol / L, the applied DC voltage is 3.0V, and the current density is 15A / dm 2 ;

[0043] Aluminum anodizing to form Al 2 o 3 membrane. The steps of the aluminum anodizing treatment include:

[0044] Step 1, use alkaline degreasing solution to degrease and degrease the surface of aluminum film, and carry out chemical polishing with acid polishing reagent to remove the oxide layer Al on the surface of aluminum film 2 o 3 , the alkaline degreasing solution is 0.1mol / L NaOH solution, the soaking temperature is 40°C, and the soaking time is 5min; the acidic polishing reagent contains H 3 PO 4 Concentration is 8.0mol / L, H 2 SO 4 The concentration is 3.5mol / L, and polishing is performed at room temperatu...

Embodiment 2

[0050] Pre-plating treatment of stainless steel substrates: conventional stainless steel metal surface pretreatment methods;

[0051] Electroplated aluminum film: the electroplating solution contains AlCl 3 The concentration is 170g / L, the HCl concentration is controlled at 1.5mol / L, the applied DC voltage is 4.0V, and the current density is 7.0A / dm 2 ;

[0052] Aluminum anodizing to form Al 2 o 3 membrane. The steps of the aluminum anodizing treatment include:

[0053] Step 1, use alkaline degreasing solution to degrease and degrease the surface of aluminum film, and carry out chemical polishing with acid polishing reagent to remove the oxide layer Al on the surface of aluminum film 2 o 3 , the alkaline degreasing solution is 0.3mol / L NaOH solution, the soaking temperature is 60°C, and the soaking time is 2min; the acidic polishing reagent contains H 3 PO 4 Concentration is 10.0mol / L, H 2 SO 4 The concentration is 4.0mol / L, and polishing is performed at room tempera...

Embodiment 3

[0059] Pre-plating treatment of stainless steel substrates: conventional stainless steel metal surface pretreatment methods;

[0060] Electroplated aluminum film: the electroplating solution contains AlCl 3 The concentration is 190g / L, the HCl concentration is controlled at 2.5mol / L, the applied DC voltage is 6.0V, and the current density is 1.0A / dm 2 ;

[0061] Aluminum anodizing to form Al 2 o 3 membrane. The steps of the aluminum anodizing treatment include:

[0062] Step 1, use alkaline degreasing solution to degrease and degrease the surface of aluminum film, and carry out chemical polishing with acid polishing reagent to remove the oxide layer Al on the surface of aluminum film 2 o 3 , the alkaline degreasing solution is 0.5mol / L NaOH solution, the soaking temperature is 80°C, and the soaking time is 0.25min; the acidic polishing reagent contains H 3 PO 4 Concentration is 13.0mol / L, H 2 SO 4 The concentration is 5.0mol / L, and the polishing is carried out at roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com