A kind of fusion bonded epoxy powder material, coated steel pipe and its preparation method and application

A technology of fusing epoxy powder and steel pipes, applied in powder coatings, epoxy resin coatings, coatings, etc., can solve problems such as thin color marking lines, easy-to-fall-off identification of identification plates, unclear identification, etc., to achieve good resistance Static electricity, rich color appearance, high recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

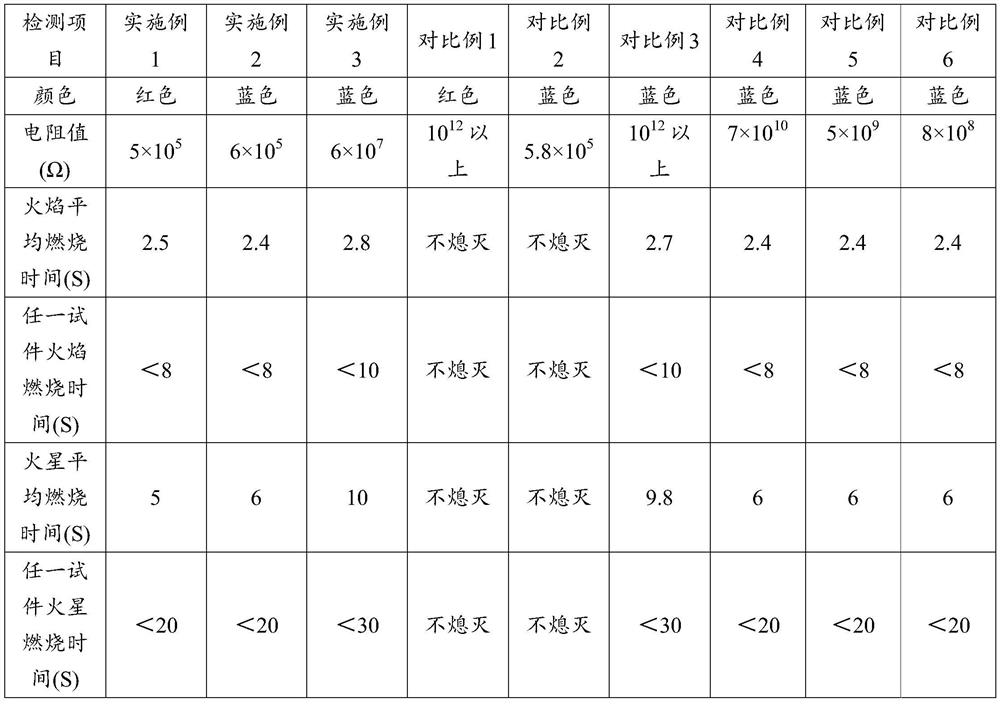

Examples

Embodiment 1

[0042] a: Preparation of antistatic flame retardant masterbatch. The ratio by mass is: 20 parts of nano-carbon fiber, 10 parts of conductive mica, 5 parts of conductive titanium dioxide, 10 parts of brominated flame retardant, 1 part of powder coupling agent, bisphenol A epoxy resin (604) 54 share. After mixing various raw materials by a high-speed mixer, a sheet is prepared by a twin-screw extruder and a tablet press, and then crushed by an ACM mill to prepare an antistatic and flame-retardant masterbatch with a particle size of 50 mesh.

[0043] b: Preparation of fusion-bonded epoxy powder with red antistatic and flame-resistant properties. The ratio by mass is: 50 parts of bisphenol A epoxy resin (604), 10 parts of phenolic curing agent (Daqing Qinglu 969F02X), 20 parts of antistatic and flame retardant masterbatch, accelerator (2-methylimidazole ) 0.1 part, leveling agent additive (Wuhan Yincai L88) 1 part, defoamer (benzoin) 0.6 part, nano filler (nano silica) 16 parts,...

Embodiment 2

[0046] a: Preparation of antistatic flame retardant masterbatch. The ratio by mass is: 20 parts of nano-carbon fiber, 10 parts of conductive mica, 5 parts of conductive titanium dioxide, 10 parts of brominated flame retardant, 1 part of powder coupling agent, bisphenol A epoxy resin (604) 54 share. After mixing various raw materials by a high-speed mixer, a sheet is prepared by a twin-screw extruder and a tablet press, and then crushed by an ACM mill to prepare an antistatic and flame-retardant masterbatch with a particle size of 50 mesh.

[0047] b: Preparation of fusion-bonded epoxy powder with blue antistatic and flame-resistant properties. The ratio by mass is: 50 parts of bisphenol A epoxy resin (604), 10 parts of phenolic curing agent (Daqing Qinglu 969F02X), 20 parts of antistatic and flame retardant masterbatch, accelerator (2-methylimidazole ) 0.1 part, leveling agent additive (Wuhan Yincai L88) 1 part, defoamer (benzoin) 0.6 part, nano filler (nano silicon dioxide)...

Embodiment 3

[0050] a: Preparation of antistatic flame retardant masterbatch. The ratio by mass is: 10 parts of nano-carbon fiber, 10 parts of conductive mica, 20 parts of conductive titanium dioxide, 10 parts of brominated flame retardant, 1 part of powder coupling agent, bisphenol A epoxy resin (604) 49 share. After mixing various raw materials by a high-speed mixer, a sheet is prepared by a twin-screw extruder and a tablet press, and then crushed by an ACM mill to prepare an antistatic and flame-retardant masterbatch with a particle size of 50 mesh.

[0051] b: Preparation of fusion-bonded epoxy powder with blue antistatic and flame-resistant properties. The ratio by mass is: 50 parts of bisphenol A epoxy resin (604), 10 parts of phenolic curing agent (Daqing Qinglu 969F02X), 20 parts of antistatic and flame retardant masterbatch, accelerator (2-methylimidazole ) 0.1 part, leveling agent additive (Wuhan Yincai L88) 1 part, defoamer (benzoin) 0.6 part, nano filler (nano silicon dioxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com