Preparation method of polyvinyl carbazolyl gel polymer electrolyte capacitor

A polyvinyl carbazole-based gel and capacitor technology, which is applied in the field of capacitors, can solve the problems of poor contact, large internal resistance, and complicated film-making process, and achieve the effects of reducing internal resistance, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

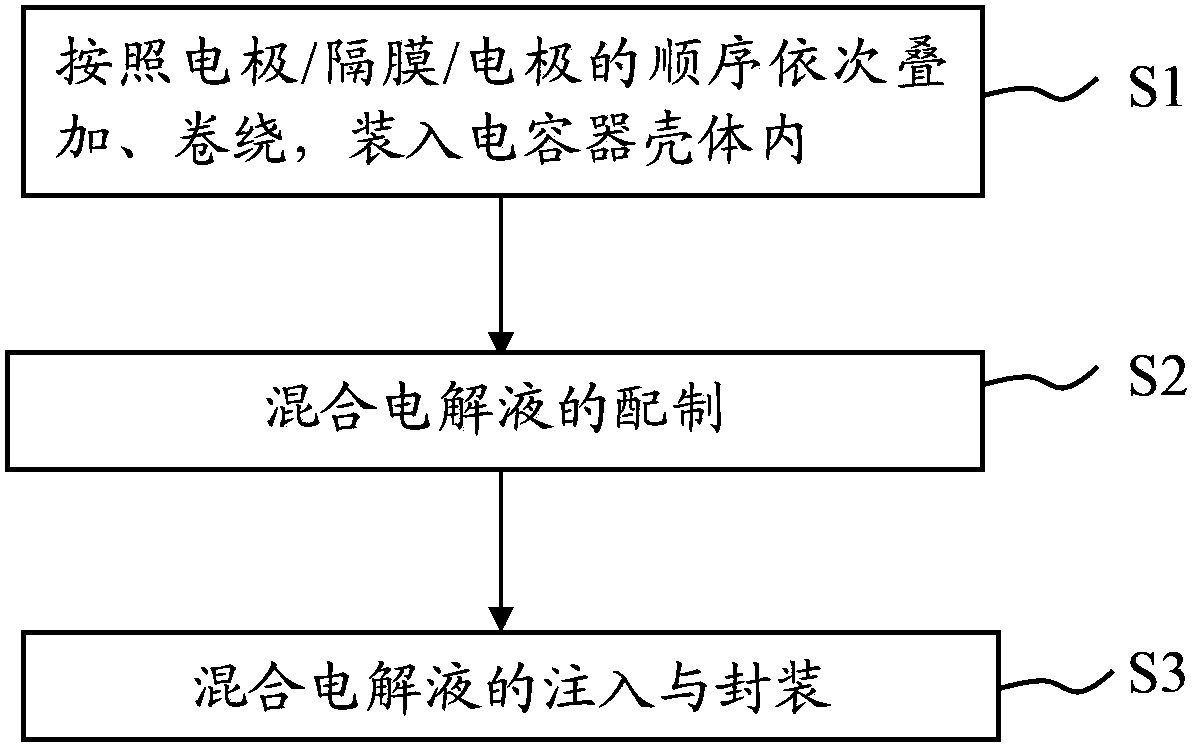

[0013] The embodiment of the present invention provides a method for preparing a polyvinylcarbazole-based gel polymer electrolyte capacitor with excellent compatibility between the gel polymer electrolyte and electrode materials and a simple process. The process flow of this method is as figure 1 As shown, it includes the following steps:

[0014] S01: Stack and wind in sequence according to the order of electrodes / diaphragms / electrodes, and put them into the capacitor case;

[0015] S02: Preparation of mixed electrolyte: mix 0.5-2 mol / L pyrrolidine ionic liquid electrolyte, vinyl carbazole and initiator in a mass ratio of (5-10):1:(0.002-0.02) to obtain mixture;

[0016] S03: Injection and packaging of the mixed electrolyte: inject the mixed solution prepared in step S02 into the capacitor case, seal it, and place it at 60°C-80°C for polymerization reaction for 12-48 hours to obtain polyvinylcarbazole (PVK) based gel polymer electrolyte capacitors.

[0017] Specifically, ...

Embodiment 1

[0025] A preparation method for a PVK-based gel polymer electrolyte capacitor, comprising the steps of:

[0026] S11: Preparation of graphene electrodes:

[0027] Take graphene (specific surface area is 1000m 2 / g) 4.5g, acetylene black 0.26g, PVDF 0.41g, and NMP (40g) was added, fully stirred to make it into a uniform slurry, and then it was scraped on the aluminum foil cleaned by ethanol, at 0.01MPa Dry to constant weight at 100°C under vacuum, and roll press under 15MPa pressure to make graphene electrode. The thickness of the prepared graphene electrode is about 140 μm.

[0028] S12: Preparation of Gel Polymer Electrolyte Capacitor:

[0029] In a glove box filled with argon, the prepared graphene electrodes were stacked and wound in the order of electrode / celgardM825 separator / electrode, and packed into the capacitor case. The pre-prepared 1mol / L PYR 14 BF 4 / AN, vinyl carbazole and initiator BPO are mixed evenly in a mass ratio of 9:1:0.01, then the mixed solution i...

Embodiment 2

[0031] A preparation method for a PVK-based gel polymer electrolyte capacitor, comprising the steps of:

[0032] S21: Prepare graphene electrode:

[0033] Take graphene (specific surface area is 800m 2 / g) 4.5g, acetylene black 0.23g, PVDF 0.27g, and NMP (16g) was added, fully stirred to make it into a uniform slurry, and then it was scraped on the aluminum foil cleaned by ethanol, at 0.01MPa Dry to constant weight at 100°C under vacuum, and roll-press under 15MPa pressure to form a graphene electrode. The thickness of the obtained graphene electrode is about 100 μm.

[0034] S22: Preparation of Gel Polymer Electrolyte Capacitor:

[0035]In a glove box filled with argon, the prepared graphene electrodes were stacked and wound in the order of electrode / celgard2325 separator / electrode, and packed into the capacitor case. The pre-prepared 0.5mol / L PYR 14 BF 4 / PC, vinyl carbazole, and initiator tert-butyl hydroperoxide are mixed evenly in a mass ratio of 5:1:0.002, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com