Vertically-coupled surface-etched grating DFB laser

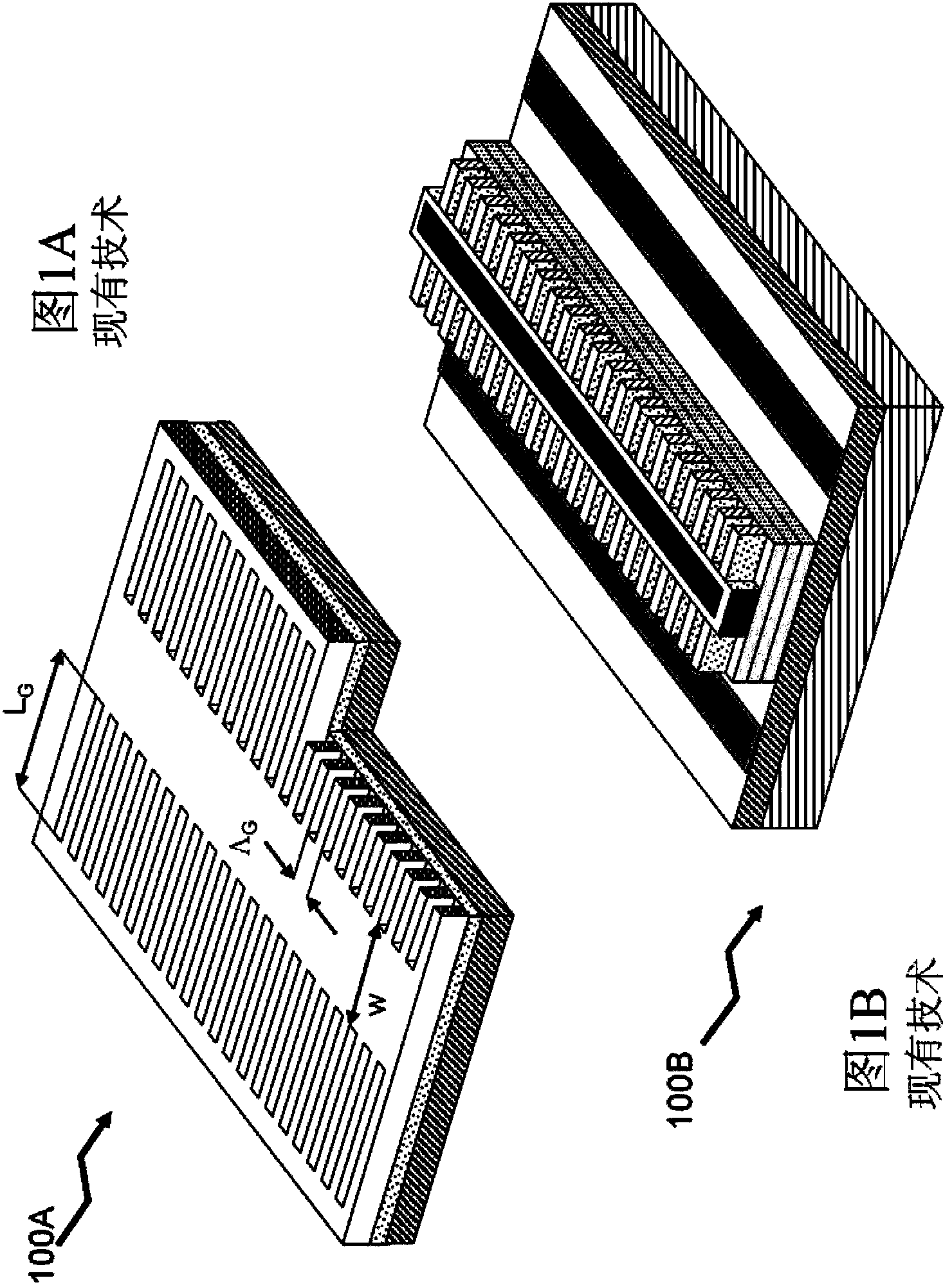

A surface grating and surface etching technology, applied in the design field of distributed feedback lasers, can solve problems such as affecting coupling efficiency and optical mode overlap scattering loss, and achieve the effect of simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

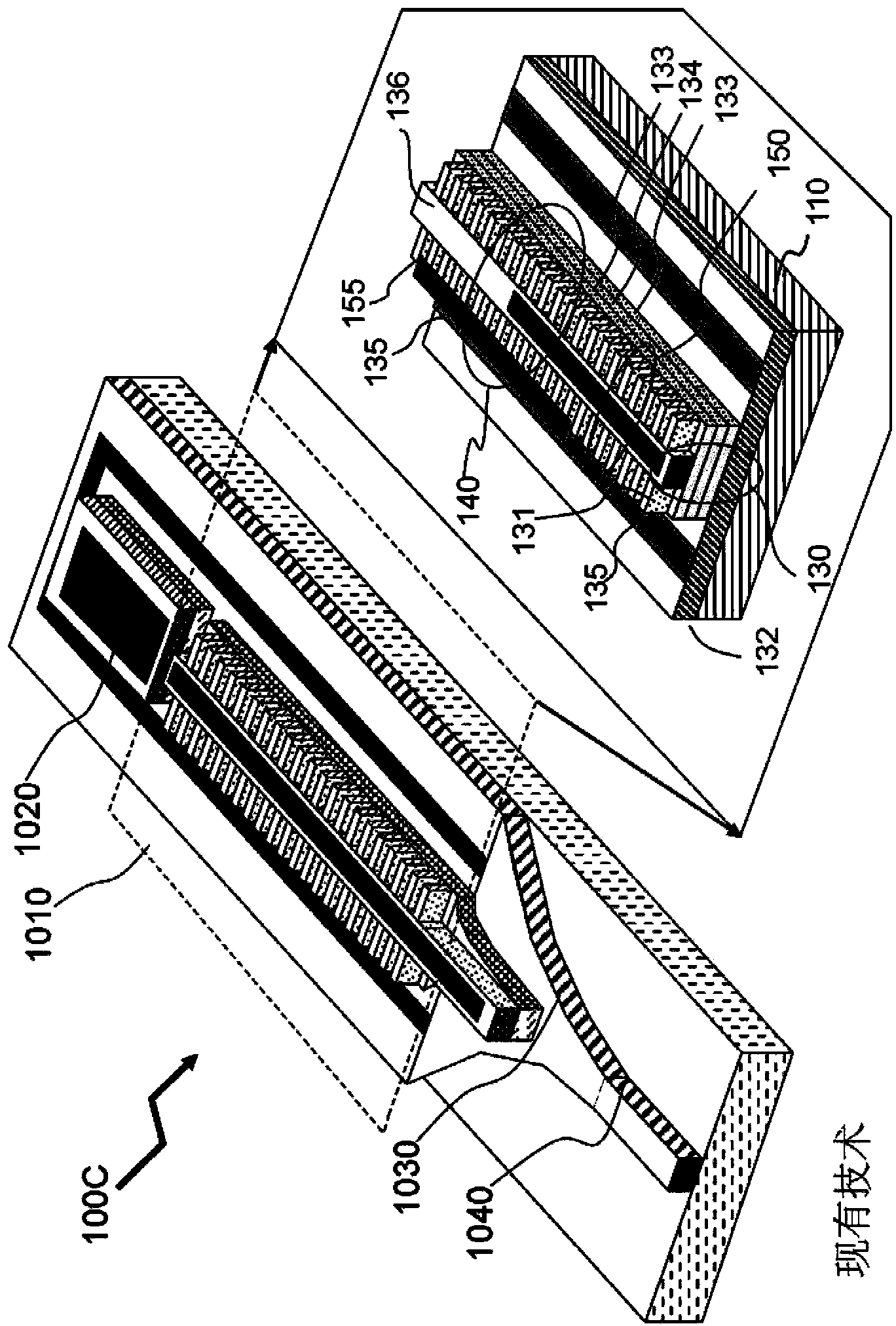

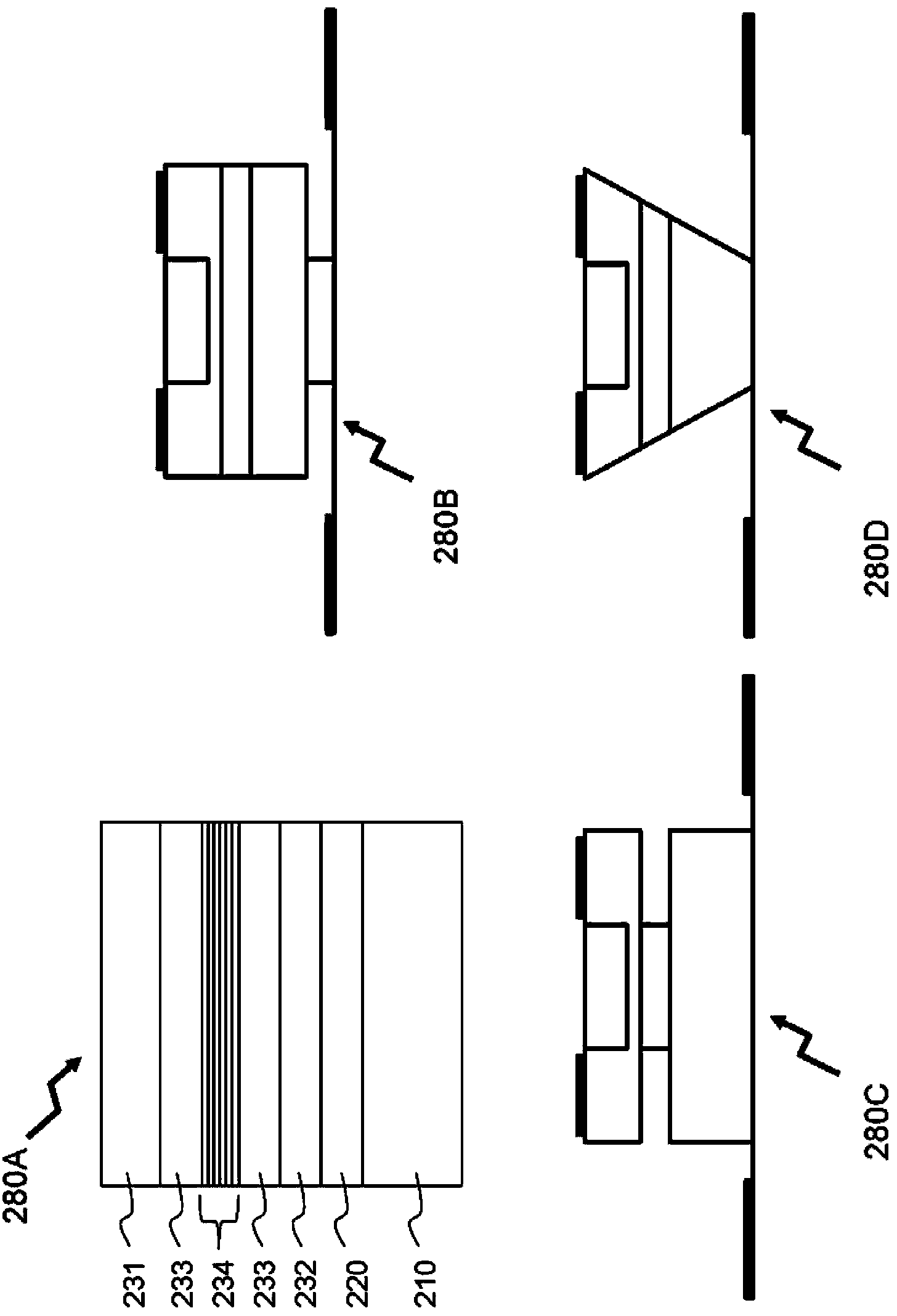

[0043] The present invention aims to provide a device involving a SEG-DFB laser that increases the overlap between the guided optical mode propagating in the waveguide of the laser and the VC-SEG to facilitate the arrangement of an efficient DFB laser cavity, which in turn can be achieved by using side-coupled SEG Increase the laser performance and reduce the limitations of the existing technology, such as lower coupling efficiency, higher intracavity loss, and greater influence of SEG processing defects on coupling efficiency and intracavity loss.

[0044] The elements shown below are understood by reference to the numbering in the figures. The following discussion is exemplary in nature only and is not intended to limit the scope of the invention. The scope of the present invention is defined only by the claims and should not be construed as limited to the implementation details described below. It will be understood by those skilled in the art that said elements may be rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com