Standardized processing technology of Chinese herbal piece stewed aconite

A processing technology and a technology for traditional Chinese medicine decoction pieces, which are applied in the field of standardized processing technology of traditional Chinese medicine decoction pieces and simmered aconite to achieve the effects of reducing the loss of active ingredients, strengthening the effects of yang-boosting, warming and relieving pain, and excellent quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

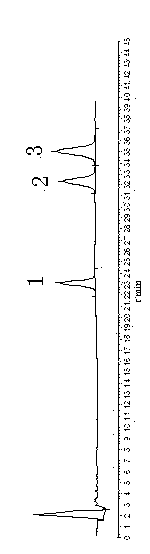

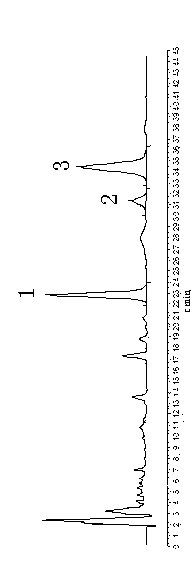

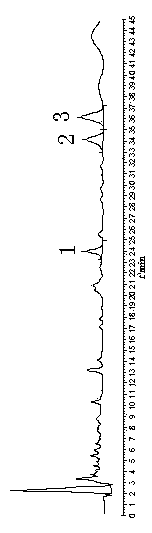

Image

Examples

Embodiment 1

[0040] The standardized processing technology of embodiment 1 traditional Chinese medicine decoction pieces stewed aconite:

[0041] Step 1: Take salt aconite, select the grades, put it in a container, add water to completely submerge the salt aconite, soak for 48 to 94 hours, change the water twice a day, until the conductivity of the soaking water drops to 4000μs / cm (25°C) When the time comes, take it out, drain the water, and set aside.

[0042]Step 2: Take the drained aconite, put the swollen part upwards, spread it evenly in 20cm thick clean burnt chaff ash, cover it with several layers of clean ginger slices, according to step 1 per 100kg Add 12kg of ginger to the prepared product, cover 2 straw papers on the ginger slices, spread a layer of 5cm thick net fine bran ash on the paper, and spread a small amount of dry bran shells on the ash; ignite at the four corners of the flat dry chaff shells , control the temperature of the upper end of the aconite at 140-160°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com