Preservation method of ultrafiltration membrane

A preservation method, ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of increasing storage and transportation costs, easy breeding of mold, algae and bacteria, leakage of moisturizing fluid, etc., and meet the requirements of reduction and storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation concentration is the sodium citrate solution standby of 4.76wt%;

[0038] Soak the ultrafiltration membrane in the above-mentioned sodium citrate solution for 2 hours, the ambient temperature is 25°C, and the ambient relative humidity is 60%;

[0039] After the soaking treatment, take out the ultrafiltration membrane and dry it in the air. The ambient temperature for drying is 25°C and the relative humidity of the environment is 60%;

[0040] After drying, store the ultrafiltration membrane at an ambient temperature of 25°C and an ambient relative humidity of 50%.

[0041] After long-term storage, the surface of the ultrafiltration membrane has no abnormal changes, and the membrane filaments have no mold, algae, odor, etc. decay.

[0042] According to the method described above, the water flux test was carried out on the ultrafiltration membrane treated by this method. The test results show that the average water flux of a single membrane filament is 501LMH ...

Embodiment 2

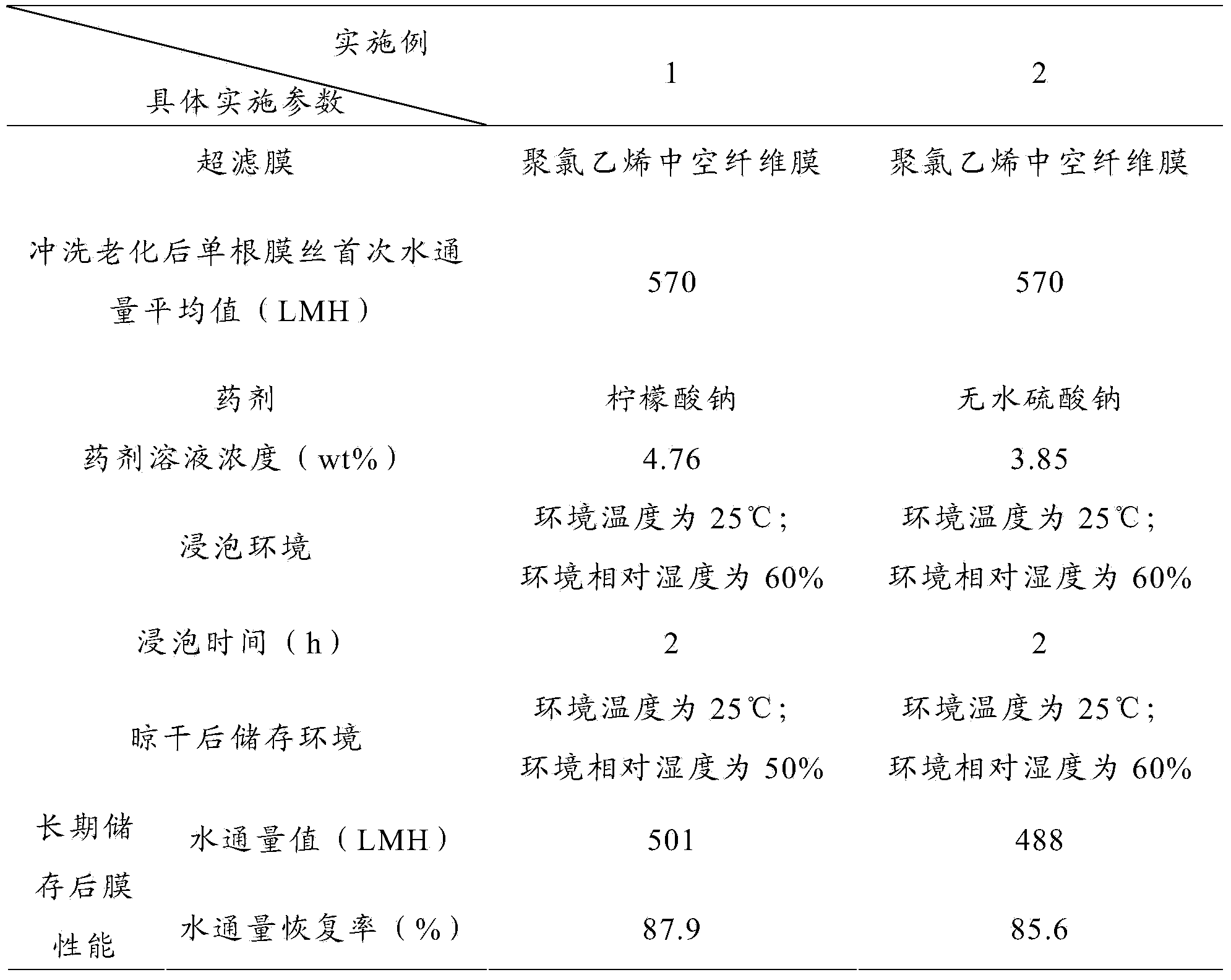

[0044] Refer to Example 1 for the actual operation, and refer to Table 1 for the detailed parameters. Table 1 is the specific implementation parameters of the ultrafiltration membrane preservation method provided by Examples 1 and 2 of the present invention. It can be seen from Table 1 that after long-term storage, the average water flux of a single membrane filament of the ultrafiltration membrane is 488LMH (liter / square meter / hour), and the water flux recovery rate is 85.6%, indicating that the ultrafiltration membrane has been effectively Keep it moisturised.

[0045] The concrete implementation parameter of the preservation method of the ultrafiltration membrane that table 1 embodiment of the present invention 1 and 2 provides

[0046]

[0047] As can be seen from the above examples, the average water flux of a single membrane filament of the ultrafiltration membrane treated by the present invention can reach 501LMH (liter / square meter / hour), and the water flux recovery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com