A fluidized bed device for preparing aromatics from alkanes and its preparation method

A fluidized bed, aromatics technology, applied in chemical instruments and methods, chemical recovery, organic chemistry, etc., can solve the problems of difficult to improve conversion rate and aromatics yield, low process driving force, influence of heating tube strength, etc. Increase independence and operational flexibility, reduce equipment costs, and reduce the effect of heating pipe area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

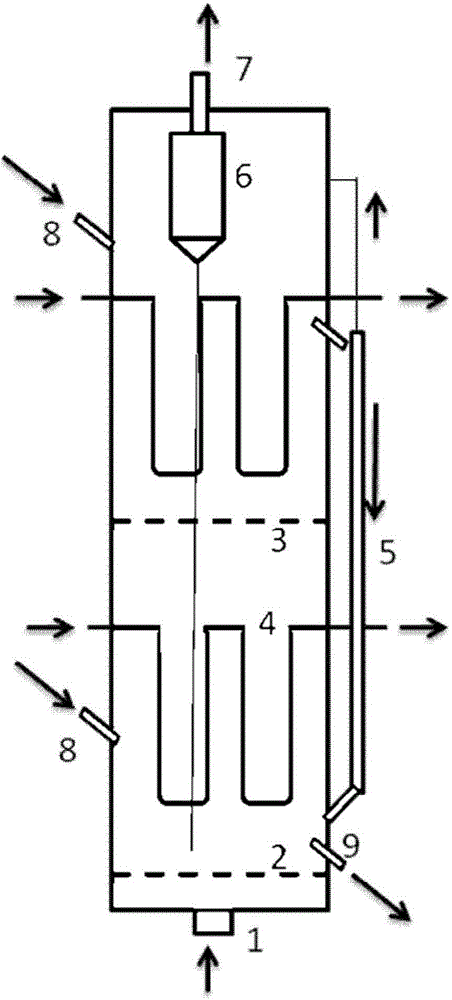

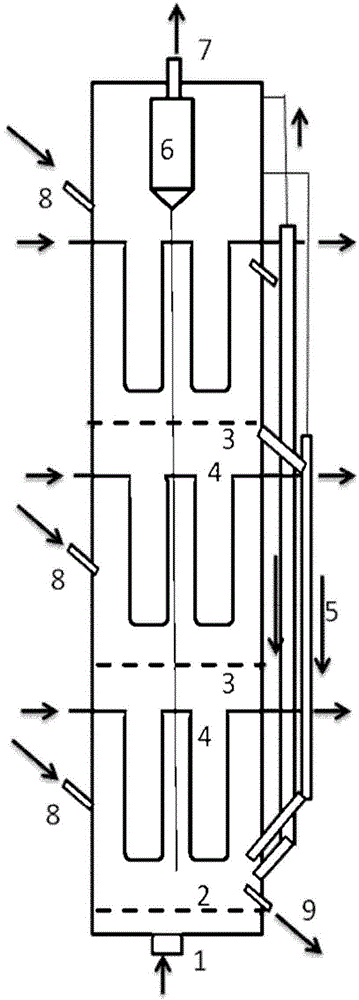

[0041] For a two-stage fluidized bed device as shown in Figure 1, the distance between the upper outlet of the outer overflow pipe and the adjacent lower distribution plate is 0.1 times the diameter of the device. The inlet of the lower part of the outer overflow pipe is located in the first layer of catalyst bed. The two catalyst inlets lead into two catalyst beds respectively, and the position of the catalyst inlet in the second catalyst bed is 0.4m higher than the upper outlet of the overflow pipe outside the device. The gas contained in the catalyst entering from the upper outlet of the outer overflow pipe is led to the vicinity of the catalyst recovery system in the device through the pipeline. The cross-sectional area of the set finned heating tube accounts for 20% of the radial cross-sectional area of the device.

[0042] While passing air at 600°C from the gas inlet 1 through the gas distributor 2, the fluidized catalyst is loaded into the device from the catalyst i...

Embodiment 2

[0046] For a two-stage fluidized bed device as shown in Figure 1, the distance between the upper outlet of the outer overflow pipe 5 and the adjacent lower distribution plate is 1 times the diameter of the device. The lower inlet of the outer overflow pipe is located in the first catalyst bed. The two catalyst inlets lead into two catalyst beds respectively, and the position of the catalyst inlet 8 in the second catalyst bed is 1.5m higher than the upper outlet of the outer overflow pipe 5 outside the device. The gas contained in the catalyst entering from the upper outlet of the outer overflow pipe is led to the vicinity of the catalyst recovery system 6 in the device through pipelines. The cross-sectional area of the set finned heating tube accounts for 35% of the radial cross-sectional area of the device.

[0047] While the air at 300°C is introduced from the gas inlet of the device through the gas distributor, the fluidized catalyst is loaded into the device from the ...

Embodiment 3

[0051] For a two-stage fluidized bed device as shown in Figure 1, the distance between the upper outlet of the outer overflow pipe and the adjacent lower distribution plate is twice the diameter of the device. The lower inlet of the outer overflow pipe is located in the first catalyst bed. The two catalyst inlets lead into two catalyst beds respectively, and the position of the catalyst inlet in the second catalyst bed is 1m higher than the upper outlet of the overflow pipe outside the device. The gas contained in the catalyst entering from the upper outlet of the outer overflow pipe is led to the vicinity of the catalyst recovery system in the device through the pipeline. The cross-sectional area of the set finned heating tube accounts for 25% of the radial cross-sectional area of the device.

[0052] While nitrogen gas at 600°C is introduced from the gas inlet through the gas distributor, the fluidized catalyst is loaded into the device from the catalyst inlet. The main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com