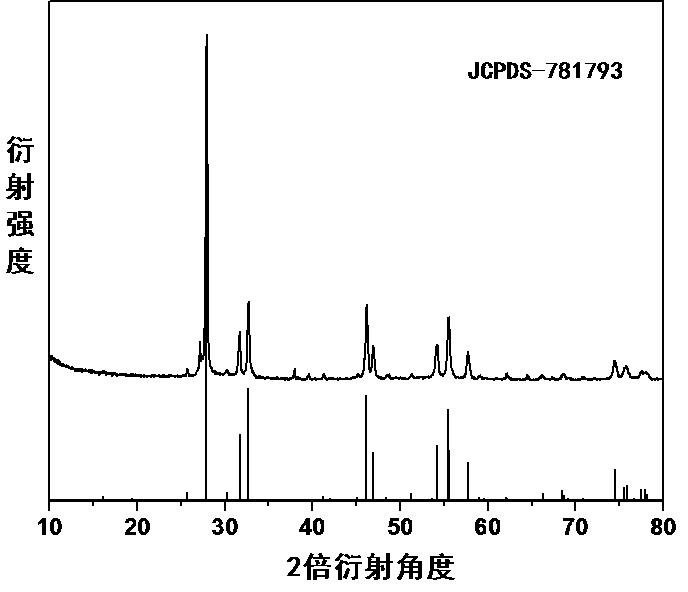

Method for preparing bismuth trioxide nanowires by using solid-phase chemical reaction

A solid-phase chemical reaction, bismuth trioxide technology, applied in chemical instruments and methods, inorganic chemistry, nanotechnology and other directions, can solve the problems of high cost, poor thermal stability of materials, complex synthesis process, etc., and achieve high product yield. , the preparation method is simple, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Accurately weigh 0.01 mol of bismuth nitrate and 0.02 mol of oxalic acid in different mortars, grind them separately and mix them evenly. After mixing, grind them quickly. As the grinding progresses, the mixture turns into a white paste. Continue grinding for 30 minutes to ensure sufficient reaction conduct. The precursor was placed in a muffle furnace, raised to 300°C at a rate of 10°C / min, and calcined at this temperature for 30 minutes. The obtained sample was washed with deionized water and dried at room temperature to obtain bismuth trioxide nanowires.

Embodiment 2

[0015] Accurately weigh 0.01 mol of bismuth nitrate and 0.03 mol of sodium oxalate in different mortars, grind them separately and mix them evenly. After mixing, grind quickly. As the grinding progresses, the mixture turns into a white paste. Continue grinding for 30 min to ensure the reaction is complete. fully carried out. The precursor was placed in a muffle furnace, raised to 300°C at a rate of 8°C / min, and calcined at this temperature for 30 minutes. The obtained sample was washed with deionized water and dried at room temperature to obtain bismuth trioxide nanowires.

Embodiment 3

[0017] Accurately weigh 0.01 mol of bismuth nitrate and 0.02 mol of ammonium oxalate in different mortars, grind them separately and mix them evenly. After mixing, grind them quickly. As the grinding progresses, the mixture turns into a white paste. Continue grinding for 30 minutes to ensure the smoothness of the reaction. fully carried out. The precursor was placed in a muffle furnace, raised to 300°C at a rate of 10°C / min, and calcined at this temperature for 30 minutes. The obtained sample was washed with deionized water and dried at room temperature to obtain bismuth trioxide nanowires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com