Process for absorption and recycling of ethylene in olefin reaction products prepared from methanol

A reaction product and methanol recovery technology, applied in ethylene production, absorption purification/separation, organic chemistry, etc., can solve the problems of increased investment, complicated process, large consumption, etc., and achieve flexible and stable operation, short circulation route, and reduced load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

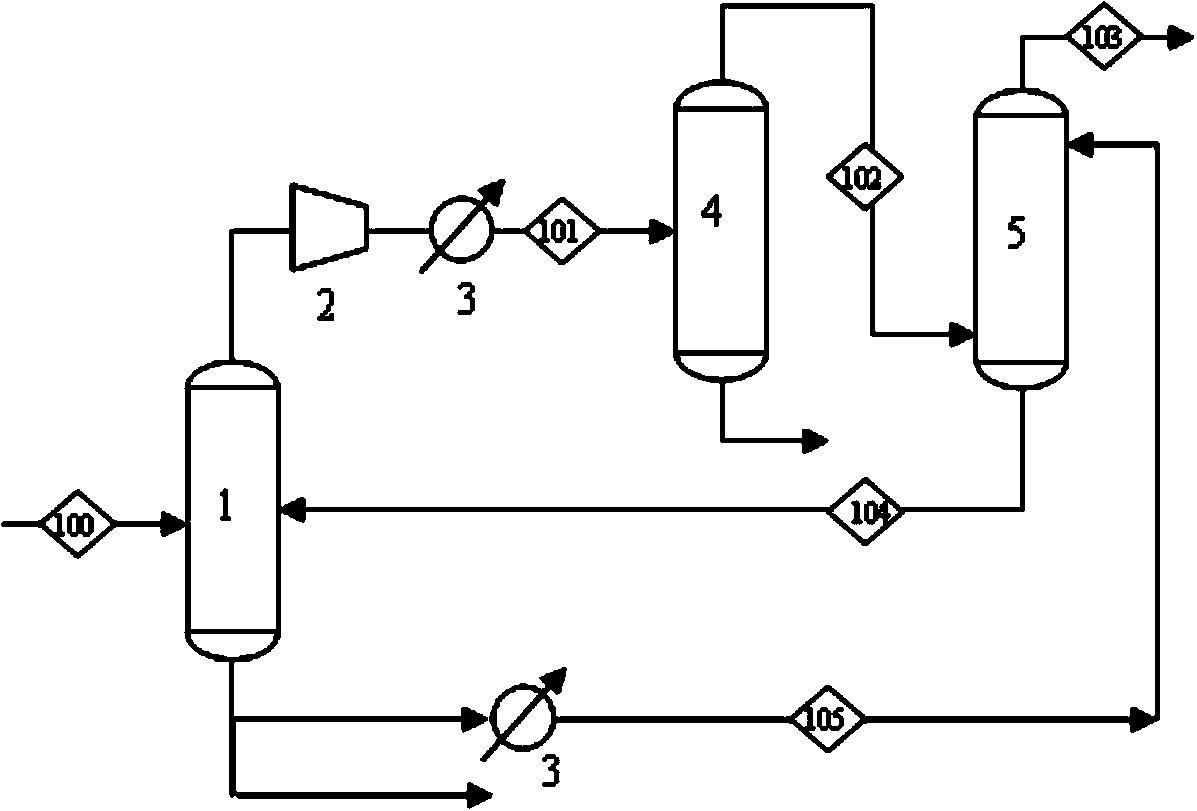

[0027] A process for absorbing and recovering ethylene in the methanol-to-olefins reaction product, such as figure 1 As shown, the outlet gas 100 of a certain reactor is compressed, washed with water, washed with alkali, deoxidized and dried, and then enters the separation system of the pre-depropanization process. Specifically, the reactor outlet gas 100 enters the depropanizer 1 to separate C3 / C4, and the products below C3 and C3 at the top of the tower are compressed by the compressor 2 and cooled to 5~-37°C by the heat exchanger 3, The obtained pretreated gas 101 enters the demethanizer 4, and the light gas 102 at the top of the demethanizer 4 enters the ethylene recovery tower 5 for absorption and separation, and the methane concentration in the bottom of the demethanizer 4 is controlled at 5-200ppm, and the ethylene The gas phase 103 at the top of the recovery tower is light component gases such as methane and hydrogen, and the product 104 in the bottom of the ethylene r...

Embodiment 2

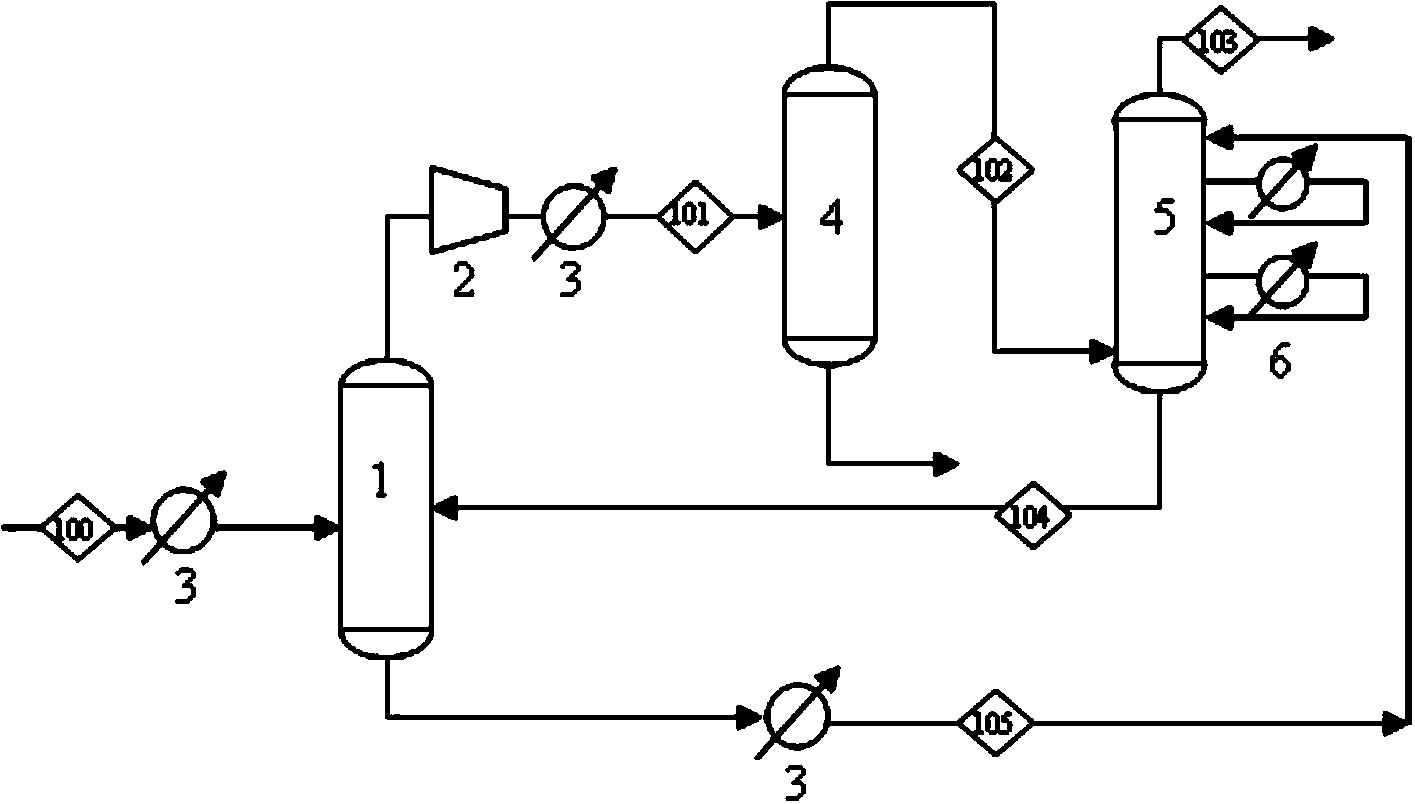

[0038] A process for absorbing and recovering ethylene in the methanol-to-olefins reaction product, such as figure 2 As shown, the process is roughly the same as that of Example 1, except that the reactor outlet gas 100 is preliminarily cooled through the heat exchanger 3 before entering the demethanizer 4 . In addition, two intercoolers 6 are provided in the ethylene recovery tower 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com