Solvent-free solid-phase catalyzed method for synthesizing hydroxyphosphonate

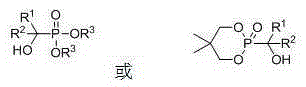

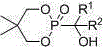

A solvent-free technique for synthesizing hydroxyphosphonate, which is applied in the field of solvent-free solid-phase catalyzed synthesis of hydroxyphosphine and hydroxyphosphonate, can solve the problems of easy deliquescence, complicated operation process, and difficult synthesis, so as to avoid the generation of waste water , Simplify the synthesis process and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a 100mL three-necked flask, add furfural (0.96g, 10mmoL), dimethyl phosphite (1.2g, 11mmoL) and potassium carbonate (1.38g, 10mmoL), stir, heat to 30°C to melt furfural, and react for about 60 Minutes, all the reactants solidified. Then 40 mL of ethyl acetate was added, stirred for 20 minutes to dissolve the product, and filtered. The filtrate was concentrated and recrystallized to obtain the product (1.94 g), with a yield of 94%. Recover solvent. Dry the filter cake for later use. 1 HNMR (CDCl 3 ,TMS,400Hz)δ3.74–3.85(m,6H,2×(O–CH 3 )),6.38(d,1H,J=13.6Hz),6.42–6.76(m,3H,C 4 h 3 O–);HRMSCalcd.forC 7 h 11 o 5 P:206.0344,found:207.1061.

Embodiment 2

[0024] In a 100mL three-necked flask, add 2-thiophenecarbaldehyde (1.12g, 10mmoL), diethyl phosphite (1.52g, 11mmoL) and potassium acetate (0.49g, 5mmoL), stir, and heat to 50°C to make 2-thiophene The formaldehyde melted and reacted for about 10 hours, and all the reactants solidified. Then 20 mL of dichloromethane was added, stirred for 20 minutes to dissolve the product, and filtered. The filtrate was concentrated and recrystallized to obtain the product (2.30 g), with a yield of 92%. Recover solvent. Dry the filter cake for later use. 1 HNMR (CDCl 3 ,TMS,400Hz)δ1.42(m,6H,2×(C–CH 3 )),3.70–3.81(m,6H,2×(O–CH 3 )),6.51(d,1H,J=13.3Hz),6.69–7.23(m,3H,C 4 h 3 S–);HRMSCalcd.forC 9 h 15 o 4 PS: 250.0429, found: 251.1161.

Embodiment 3

[0026] In a 100mL three-necked flask, add 2-acetylfuran (1.10g, 10mmoL), dibutyl phosphite (1.14g, 11mmoL) and potassium carbonate (0.69g, 5mmoL), stir, and heat to 70°C to make 2-acetylfuran The furan melted and reacted for about 24 hours, and all reactants solidified. Then 40 mL of ethyl acetate was added, stirred for 20 minutes to dissolve the product, and filtered. The filtrate was concentrated and recrystallized to obtain the product (2.86g) with a yield of 94%. Recover solvent. Dry the filter cake for later use. 1 HNMR (CDCl 3 ,TMS,400Hz)δ1.31(m,12H,4×(C–CH 3 )), 1.5(m,2H,2×(O–CH))1.67(d,3H,J=15.6Hz,CH 3 ),3.70–3.81(m,6H,2×(O–CH 3 )),6.47(d,1H,J=13.6Hz),6.62-7.27(m,3H,C 4 h 3 O–);HRMSCalcd.forC 12 h 21 o 5 P:276.1127,found:277.2081.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com