Method for reducing melting point of inorganic nano phase change energy storage material

A phase change energy storage material and inorganic nanotechnology, applied in the field of low-carbon energy saving in buildings, can solve the problems of supercooling and phase separation of phase change energy storage materials, and achieve the effects of low cost, simple process, stable quality and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

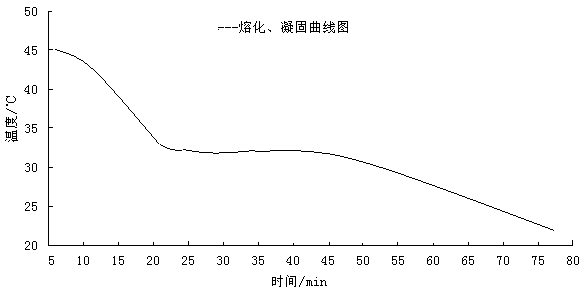

Embodiment 1

[0016] (1) Weigh 1.4g of sodium chloride NaCl, sodium sulfate NaCl 10 2 SO 4 10H 2 O 398.6g, a total of 400g, add 1000ml of water, just completely dissolve the sodium chloride and sodium sulfate 10H2O, if there is any insoluble matter, heat slightly, but not more than 30°C, to dissolve completely, add twice the volume of Absolute ethanol, stirring while adding, produces nano-sized NaCl and Na 2 SO 4 10H 2 O core material;

[0017] (2) Weigh 322g of tetraethyl orthosilicate, 278g of manganese nitrate, a total of 600g as the wall material source, the weight ratio of wall material to core material is 6:4, and the ratio of ethyl orthosilicate to manganese nitrate is 1:1;

[0018] (3) Add ethyl orthosilicate and manganese nitrate in step (2) to step (1), and stir while adding, so that ethyl orthosilicate and manganese nitrate are hydrolyzed;

[0019] (4) Stir the mixture in step (3) at a speed of 600-1000r / min for 2 hours, so that the hydrolyzed nano-wall material silica gel ...

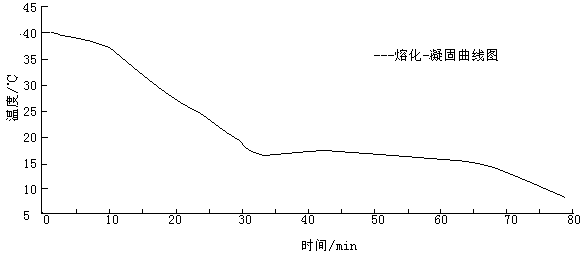

Embodiment 2

[0022] (1) Weigh 14g of sodium chloride NaCl, 10 water of sodium sulfate Na 2 SO 4 10H 2 O 386g, 400g in total, add water 1000ml, make sodium chloride and sodium sulfate decahydrate just completely dissolve, if there are insoluble matter, supplement water appropriately, make dissolving completely, add the dehydrated alcohol of double volume under constant stirring, add while adding While stirring, nano-scale NaCl and Na 2 SO 4 10H 2 O core material;

[0023] (2) Weigh 322g of tetraethyl orthosilicate, 278g of manganese nitrate, a total of 600g as the wall material source, the weight ratio of wall material to core material is 6:4, and the ratio of ethyl orthosilicate to manganese nitrate is 1:1;

[0024] (3) Add ethyl orthosilicate and manganese nitrate in step (2) to step (1), and stir while adding, so that ethyl orthosilicate and manganese nitrate are hydrolyzed;

[0025] (4) Stir the mixture in step (3) at a speed of 600-1000r / min for 2 hours, so that the hydrolyzed na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com