Polymeric imidazoline corrosion inhibitor and preparation method thereof

A technology of imidazoline corrosion inhibitor and polyacrylic acid, which is applied in the field of corrosion inhibitor anticorrosion, can solve the problem of no imidazoline corrosion inhibitor, etc., and achieve the effects of avoiding unevenness of pipelines, inhibiting corrosion, and reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

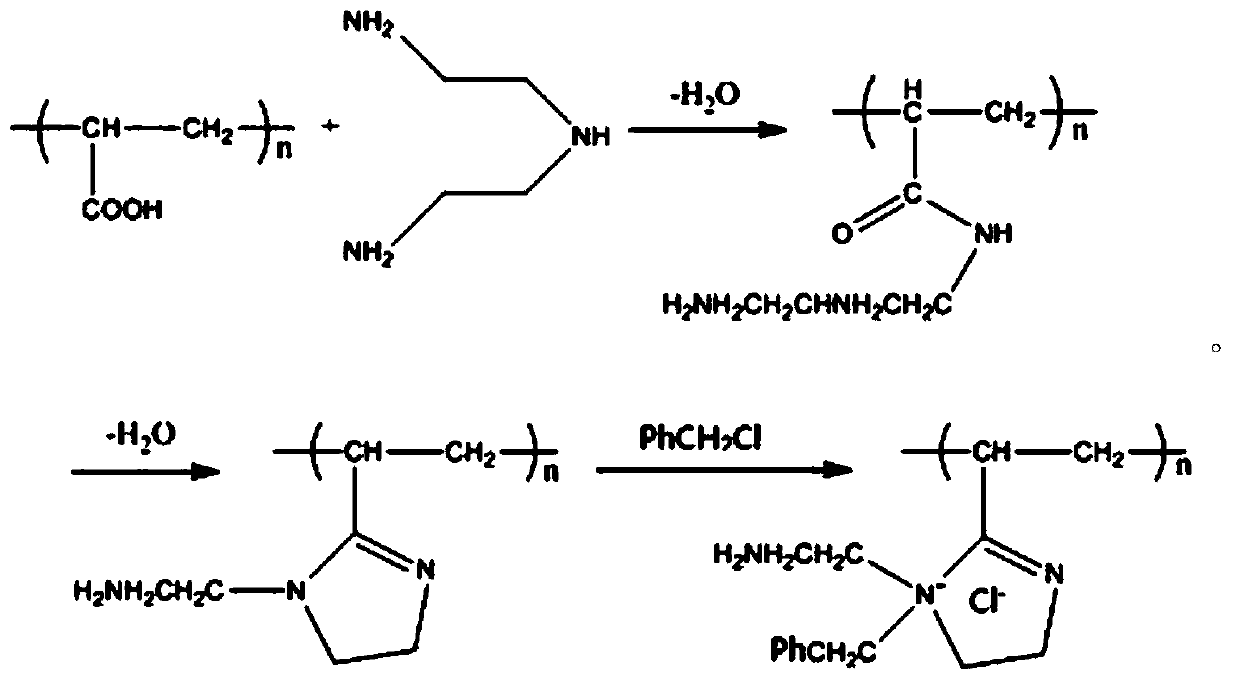

Method used

Image

Examples

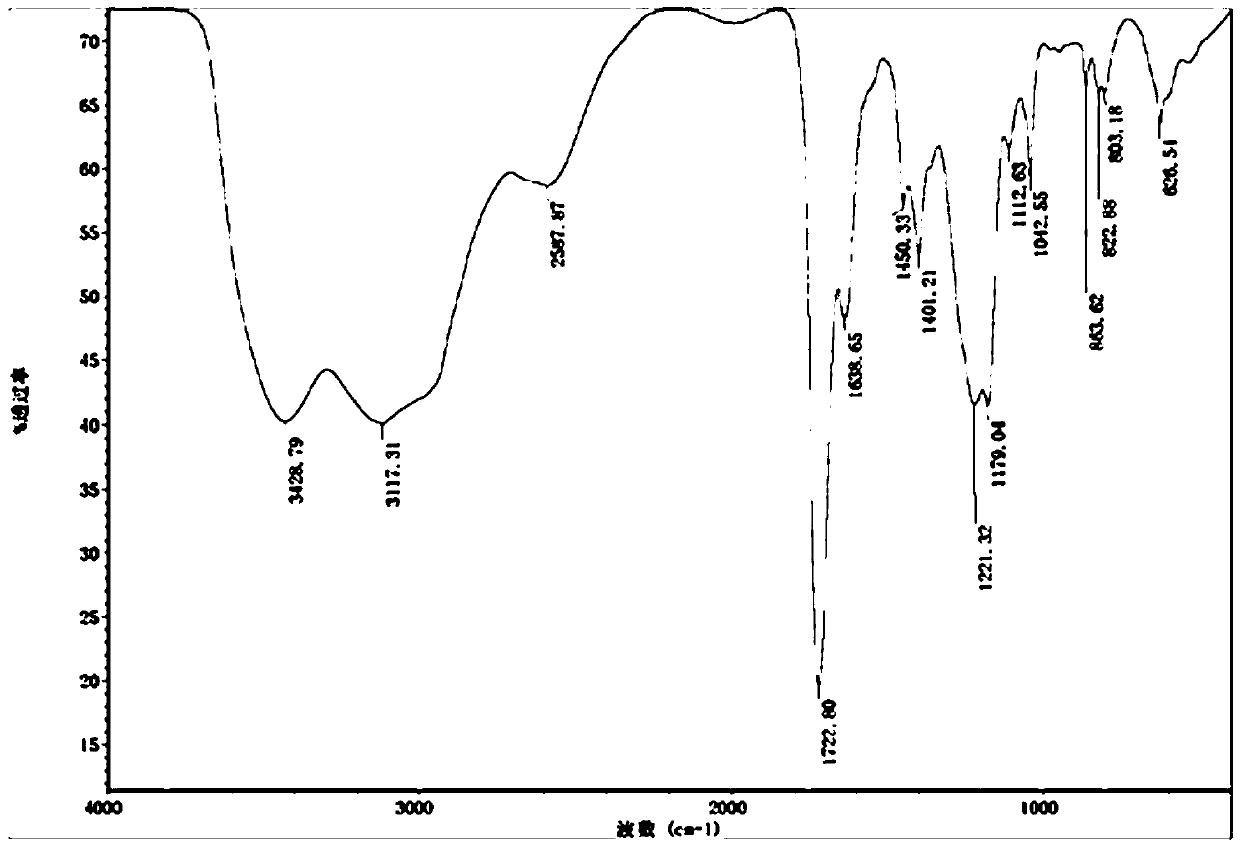

Embodiment 1

[0020] Add 120ml of polyacrylic acid solution (solid content 30%, molecular weight 2000-4000) into a 500ml three-necked flask equipped with a condenser, water separator and dropping funnel, stir mechanically, heat to 100°C, and dropwise add 68ml of diethylene Triamine and 40ml xylene solution. Water and xylene were separated from the water separator, and the reaction mixture gradually turned light yellow. The xylene in the upper layer of the water separator can be returned to the reaction system. After 5 hours of reaction, the temperature is raised to 200°C until no more water is released. At this time, the total amount of water separated should be equivalent to the amount of water generated by the stoichiometric system. Cool to 90°C, add 82ml of benzyl chloride dropwise with a dropping funnel under agitation to carry out alkylation reaction. After 3h the reaction was complete and cooled. The product was distilled off under reduced pressure to remove excess unreacted small m...

Embodiment 2

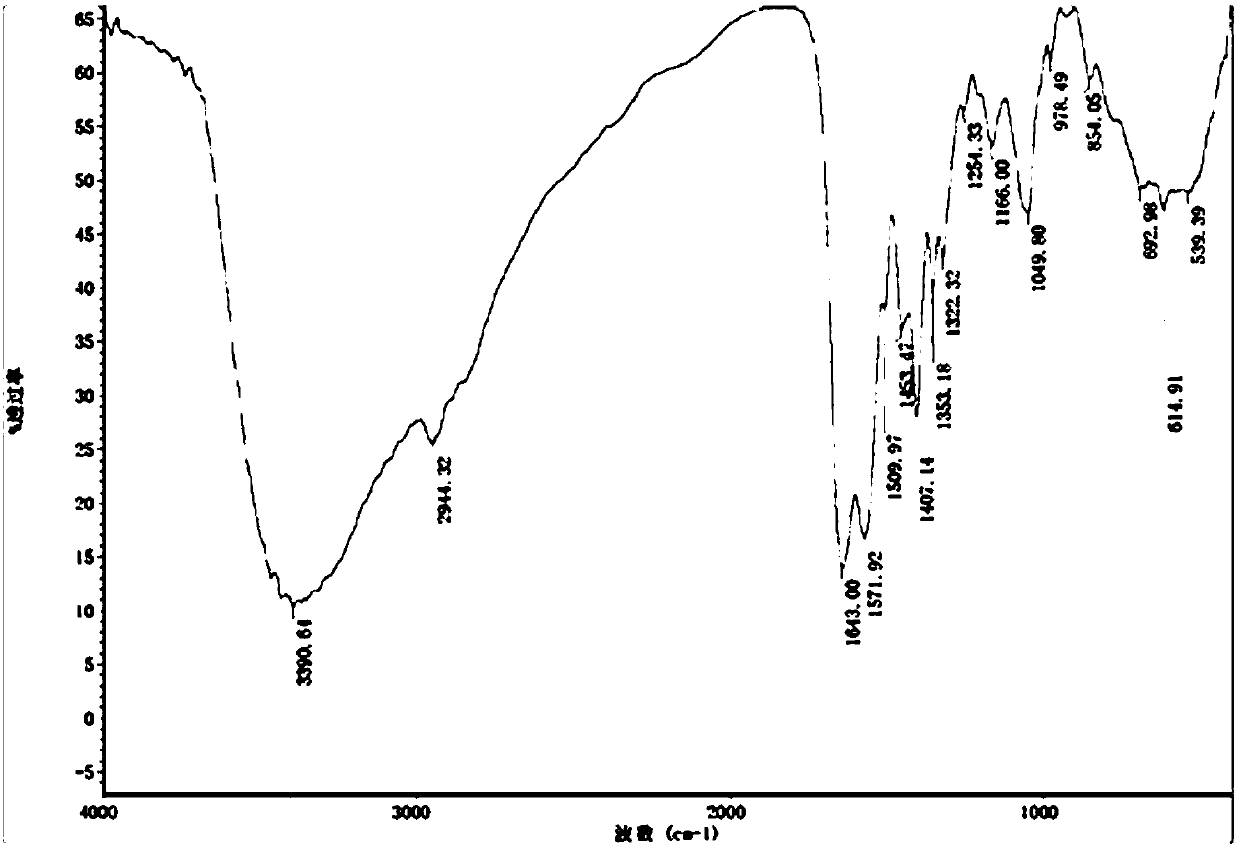

[0026] Add 72ml of polyacrylic acid solution into a 250ml four-neck flask equipped with a condenser, water separator, thermocouple and dropping funnel, stir mechanically, heat to 130°C, add dropwise 37ml of hydroxyethylethylenediamine and 40ml of di solution in toluene. The reaction mixture gradually turned yellow-brown as water and xylene were separated from the water trap. After 4 hours of reaction, the temperature was raised to 210° C., and no more water came out after 4.5 hours. Cool to 90°C, add 42ml of benzyl chloride dropwise with a dropping funnel under agitation to carry out alkylation reaction. After about 4h, the reaction was completed and cooled. The product was distilled off under reduced pressure to remove excess unreacted small molecule raw materials to obtain light brown polyimidazoline corrosion inhibitor 2.

[0027] Corrosion test:

[0028] Put the metal test piece into acetone and ethanol and ultrasonically clean it for 30 minutes to remove oil and fat, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com