Copper indium gallium selenide solar cell preparation method

A technology of solar cells and sodium salts, which can be used in circuits, electrical components, and final product manufacturing, etc., and can solve problems such as cracking of Na-Mo targets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed implementation examples mentioned in the present invention all belong to the content of the invention of the present invention. However, the present invention can be implemented in many other ways that are different from the detailed implementation examples, and those skilled in the art can make similar extensions without departing from the content of the present invention. Therefore, any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention still belong to the protection scope of the technical solution of the present invention.

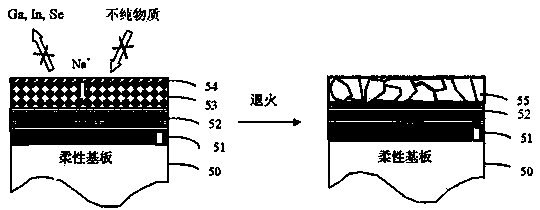

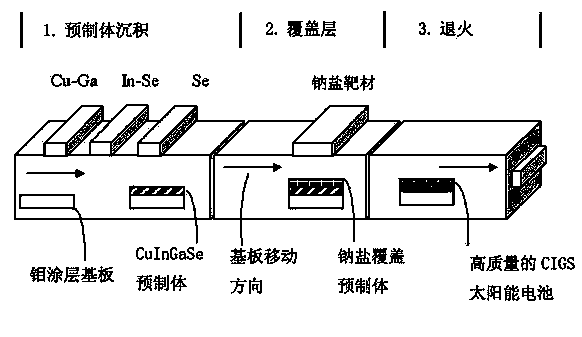

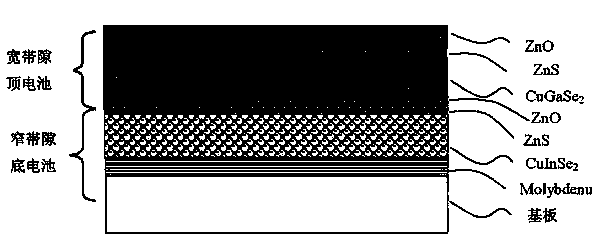

[0028] The invention provides a method for manufacturing IB-IIIA-VIA semiconductor compound, the semiconductor compound obtained by the method has good crystal grains and can be applied to the manufacture of CIGS thin film batteries. The general purpose of the present invention is to provide a kind of preparation method of copper indium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com