Multi-layer composite cathode of metal-air battery

A metal-air battery and multi-layer composite technology, which is applied to battery electrodes, electrode carriers/current collectors, circuits, etc., can solve problems such as sweating, current collector corrosion, and affecting battery life, so as to reduce corrosion, improve performance, and prolong battery life. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

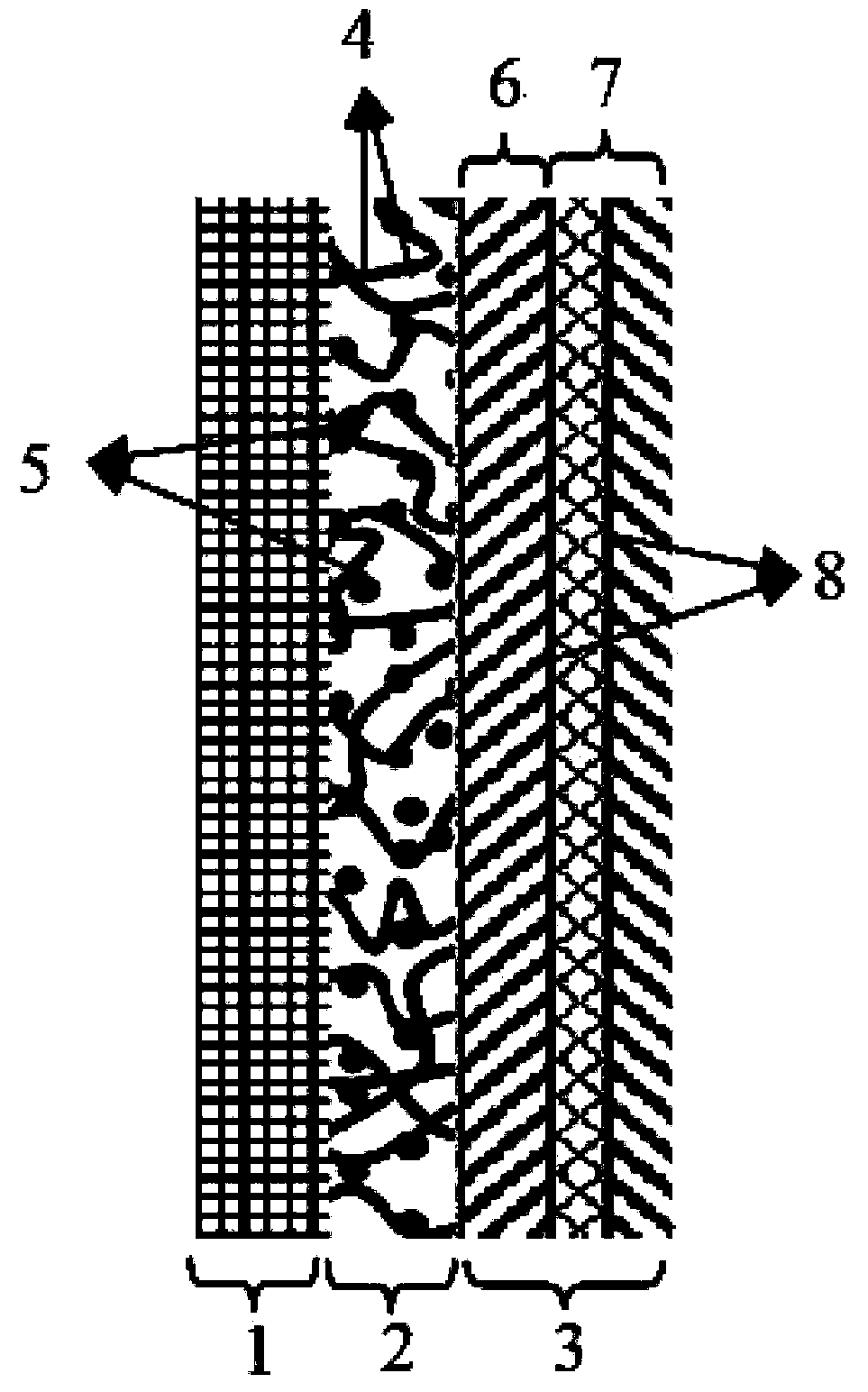

[0021] The multi-layer composite cathode for a metal-air battery in the invention includes a catalytic layer, a hydrophobic diffusion layer and a current-collecting layer.

[0022] The current collector layer is made of nickel foam current collector with a thickness of 3mm and an anti-corrosion layer coated on one side of the surface. The anti-corrosion layer is made of hydrophobic material PTFE and carbon material XC-72 with a mass ratio of 3:7 to 50 times XC- 72 mass of ethanol solvent, mixed evenly, and then coated on the surface of the current collector on one side of the foamed nickel to prepare an anti-corrosion layer with a thickness of 1 mm.

[0023] The hydrophobic diffusion layer is a carbon fiber felt after the hydrophobic treatment of the PTFE emulsion; the original thickness of the carbon fiber felt is 3.5mm; PTFE accounts for 60% of the total mass of the hydrophobic diffusion layer.

[0024] The catalytic layer is made of 60%MnO 2 / C is a catalyst, PTFE is a hyd...

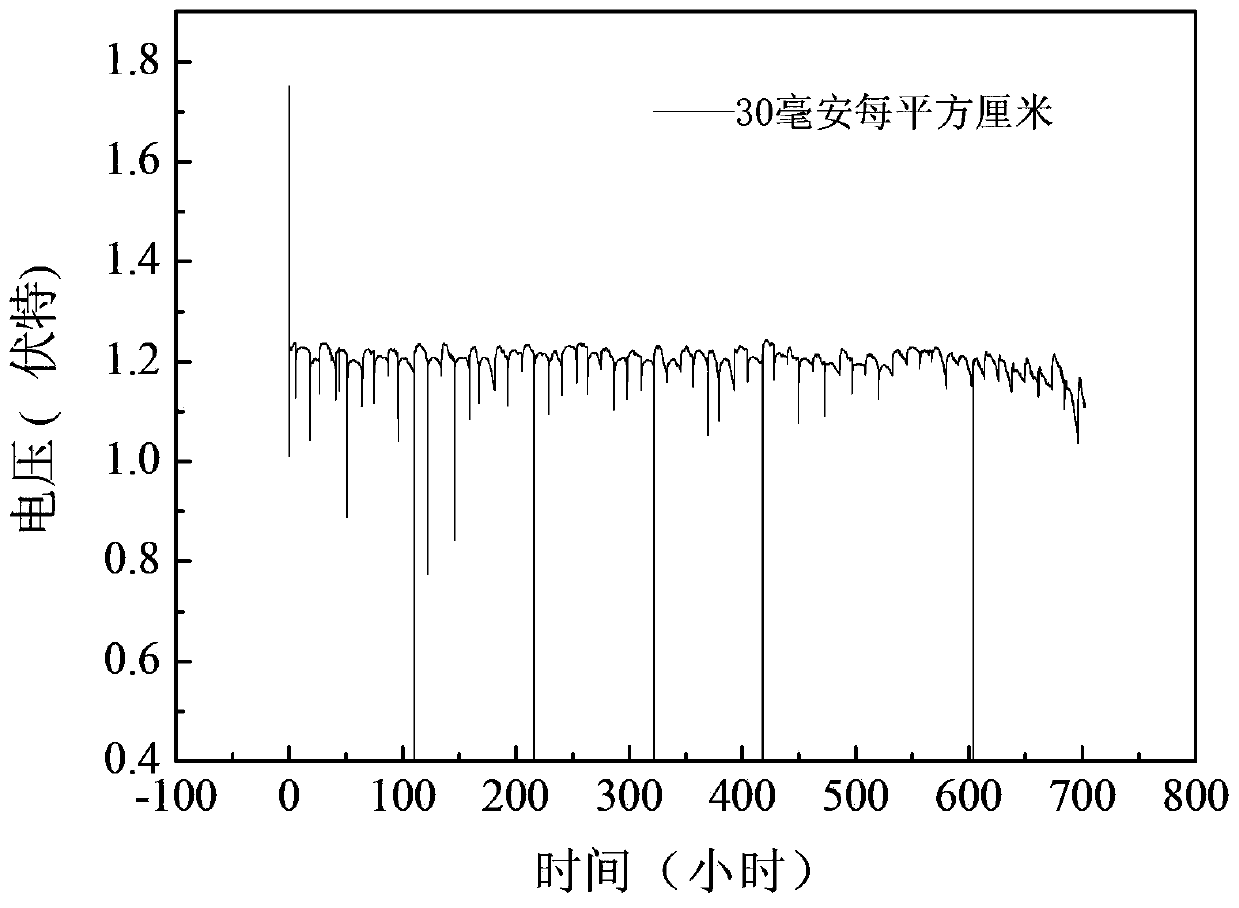

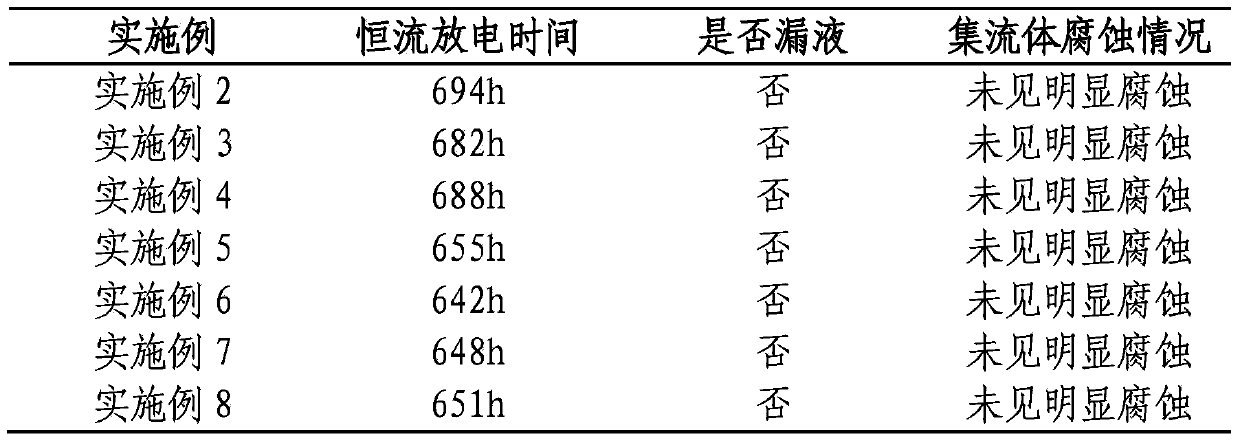

Embodiment 2

[0027] The multi-layer composite cathode for a metal-air battery in the invention includes a catalytic layer, a hydrophobic diffusion layer and a current-collecting layer.

[0028] The current collector layer is composed of foamed copper current collector with a thickness of 3mm and an anti-corrosion layer coated on one side of the surface. The thickness of the anti-corrosion layer is 1mm; It is prepared by mixing evenly in an ethanol solvent with the mass of carbon nanofibers and then coating on the surface of the current collector on both sides of the nickel foam.

[0029] The hydrophobic diffusion layer is a carbon fiber felt after the hydrophobic treatment of the PTFE emulsion; the original thickness of the carbon fiber felt is 10mm; PTFE accounts for 60% of the total mass of the hydrophobic diffusion layer.

[0030] The catalytic layer is made of 40%Mn 3 o 4 / C is a catalyst, PTFE is a hydrophobic agent; 40%Mn in the catalytic layer 3 o 4 The loading capacity of / C is...

Embodiment 3

[0033] The multi-layer composite cathode for a metal-air battery in the invention includes a catalytic layer, a hydrophobic diffusion layer and a current-collecting layer.

[0034] The current collecting layer is composed of a nickel mesh current collector with a thickness of 0.5mm and an anti-corrosion layer coated on the surface of both sides, and the thickness of the anti-corrosion layer on each side surface is 1mm; the anti-corrosion layer is composed of a hydrophobic material with a mass ratio of 9:1 PTFE and carbon nanotubes are mixed uniformly in an ethanol solvent with 50 times the mass of carbon nanotubes, and then coated on both sides of the nickel mesh.

[0035] The hydrophobic diffusion layer is a carbon fiber felt after the hydrophobic treatment of the PTFE emulsion; the original thickness of the carbon fiber felt is 3.5 mm; PTFE accounts for 60% of the total mass of the hydrophobic diffusion layer.

[0036] The catalytic layer is 40%Mn with a mass ratio of 1:1 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com