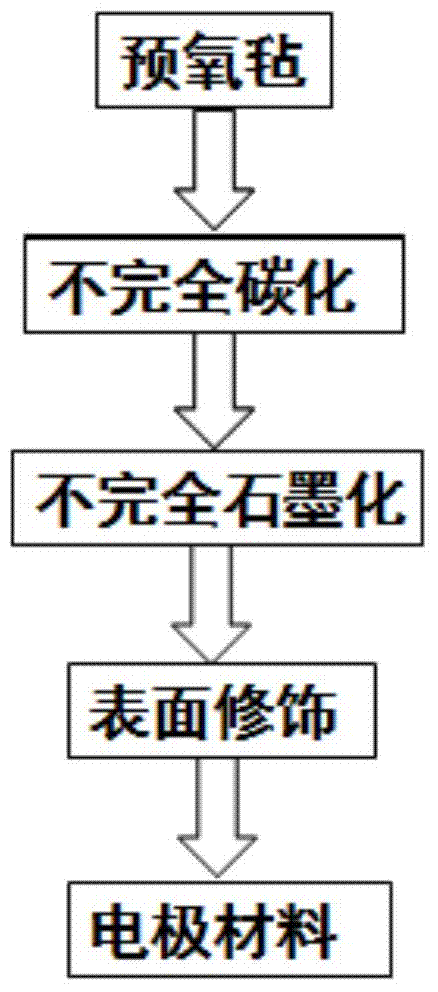

Preparation method of skin-core structure graphite felt electrode material

A skin-core structure and electrode material technology, which is applied to battery electrodes, structural parts, circuits, etc., can solve the problems of unsatisfactory flow battery electrode materials, reduced active group content, and reduced strength, so as to improve energy utilization. Improvement of activity and wettability, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The 3mm thick pre-oxygen felt was carbonized in vacuum at 800°C for 200h to incompletely carbonize the fibers. After that, graphitization is carried out. This process is carried out at 1800°C in vacuum, and the graphitization time is kept at 240h to achieve incomplete graphitization, so that the fiber has a skin-core structure. The obtained incompletely graphitized graphite felt was placed in an air atmosphere and oxidized at 400°C for 8 hours to obtain the required graphite felt electrode material.

Embodiment 2

[0024] Put the 6mm thick pre-oxygen felt in N 2 Carbonize at 1000°C for 100h to incompletely carbonize the fibers. followed by graphitization, a process in which the N 2 It is carried out at 2000°C, and the graphitization time is kept at 120h to achieve incomplete graphitization, so that the fiber has a skin-core structure. Soak the above-mentioned graphite felt in the isopropanol solution with a concentration of 2mol / L, and then perform plasma treatment on it, graft the hydroxyl groups in the isopropanol to the fiber surface of the graphite felt, and finally obtain the required graphite felt electrode material .

Embodiment 3

[0026] The 10mm thick pre-oxygen felt was carbonized in Ar at 1300°C for 30h to incompletely carbonize the fibers. After that, graphitization is carried out. This process is carried out at 2300 ° C in Ar, and the graphitization time is kept at 60 hours to achieve incomplete graphitization, so that the fiber has a skin-core structure. Put the above-mentioned graphite felt in the air atmosphere, oxidize it at 600°C for 5h, after it cools down, soak it in the mixed solution of 2mol / L isopropanol and 1mol / L acetic acid, and then carry out the above-mentioned infiltrated graphite felt By plasma treatment, the hydroxyl group in isopropanol and the carboxyl group in acetic acid are grafted onto the fiber surface of graphite felt, and finally the required graphite felt electrode material is obtained.

[0027] It is found through testing that the slag dropping phenomenon of the prepared graphite felt is significantly improved, and the content of oxygen-containing active groups on the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com