Northern greenhouse vegetable production system based on comprehensive utilization of biogas residue, biogas slurry and biogas

A production system and vegetable technology, applied in the fields of gas production bioreactors, applications, gardening methods, etc., can solve the problems of low utilization rate of "three marshes", complicated procedures, time-consuming and labor-intensive, etc. Safety factor, the effect of increasing crop yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

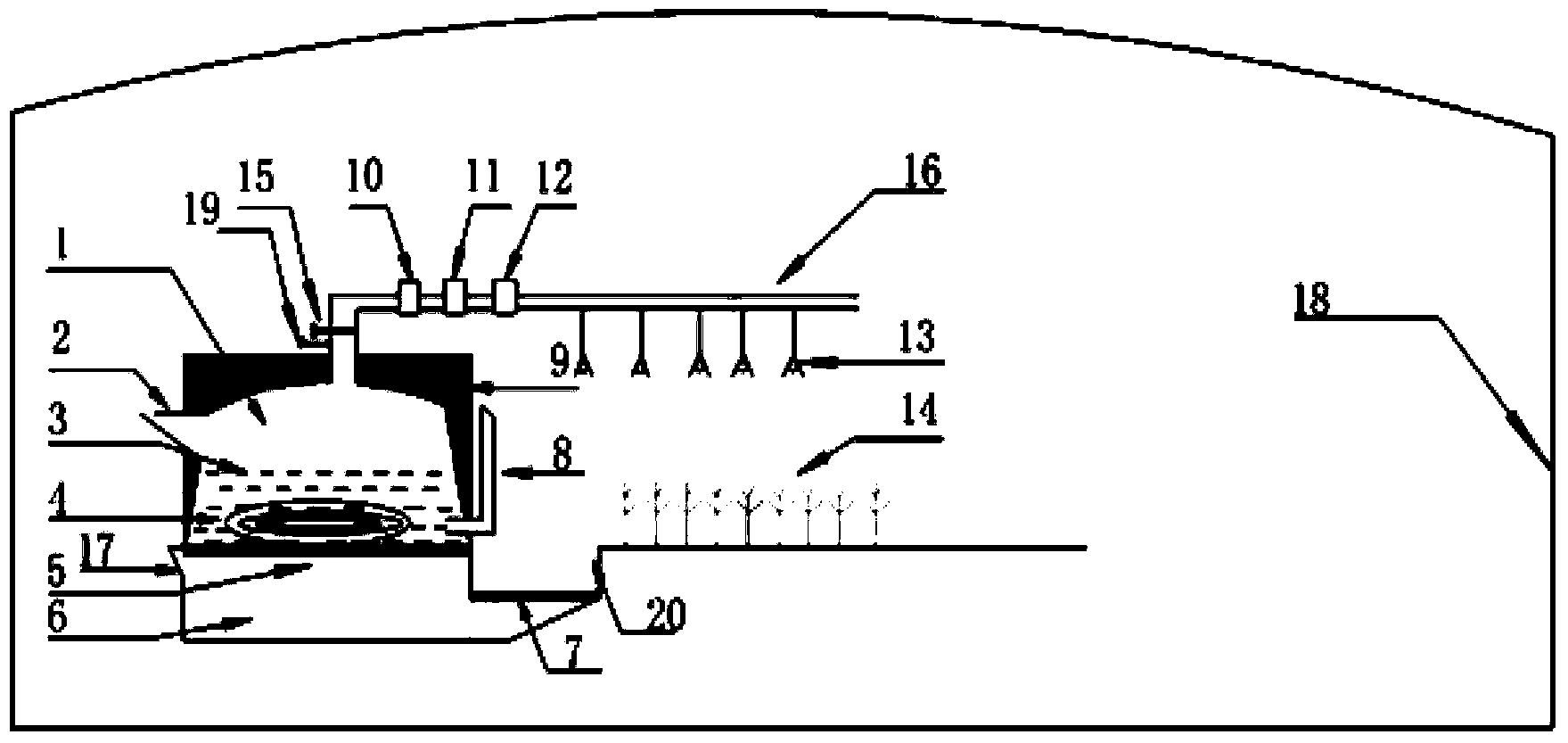

[0012] Specific Embodiment 1: The northern greenhouse vegetable production system based on the comprehensive utilization of "three biogases" in this embodiment includes a greenhouse (18), a modular biogas production system and a vegetable planting system (14), and the modular biogas The production system is arranged above the ground inside the greenhouse (18), and the vegetable planting system (14) is arranged inside the greenhouse (18).

specific Embodiment approach 2

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the modular biogas production system is composed of a gas production unit, a warming and heat preservation unit, a biogas residue and biogas liquid separation unit, and a biogas delivery unit. The unit consists of a fermentation room (3), a feed port (2), a sample outlet pipe (8), a gas storage space (1) and a gas collection port (19). The feed port (2) is set in the fermentation room (3 ), the sample outlet pipe (8) is set under the right side of the fermentation room (3), the gas collection port (19) is set above the fermentation room (3), the gas collection port (19) and the gas transmission pipeline ( 16) Connect. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the temperature-increasing and heat-retaining unit is composed of a heat-retaining room (9), a heating device (4), and a heat-insulating benzene board (5). The chamber (9) is wrapped outside the fermentation room (3), the heating device (4) is arranged at the bottom of the fermentation room (3), and the heating device (4) is located above the heat-insulating benzene plate (5). Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com