Novel modified Raney nickel catalyst, its preparation method and application

A technology of Raney nickel and catalyst, applied in the reaction of glucose hydrogenation to prepare sorbitol, the field of preparation of new modified Raney nickel catalyst material, can solve the problems of low catalytic efficiency, environmental pollution, etc., and achieve high activity, The effect of low cost and large active specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

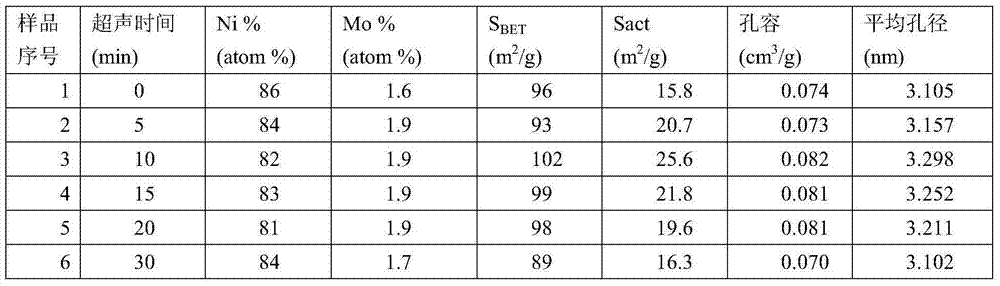

Embodiment 1

[0019] Weigh a certain amount of Ni-Al alloy with a particle size of 80-100 mesh and a Ni content of about 40-50wt% at room temperature, and slowly add it to 6mol / L NaOH solution in an ice-water bath. The ratio of the number of milliliters is 1:10, and the temperature is stirred at 343K for 4 hours. The whole process is carried out under the protection of nitrogen to prevent oxidation of the sample, and a reflux device is used to prevent changes in the concentration of the NaOH solution. After the reaction, the supernatant was removed, and the black particles were repeatedly washed with deionized water to neutrality, and then washed with absolute ethanol to remove water, and stored in absolute ethanol; take 0.5g of Raney nickel particles at room temperature at 293 Place it in 10mL of deionized water at -298K, the ratio of the weight of Raney nickel in grams to the volume of water in milliliters is 1:20, slowly add 2mL of 0.1mol / L Na 2 MoO 4 Solution (containing Mo0.0192 gram)...

Embodiment 2

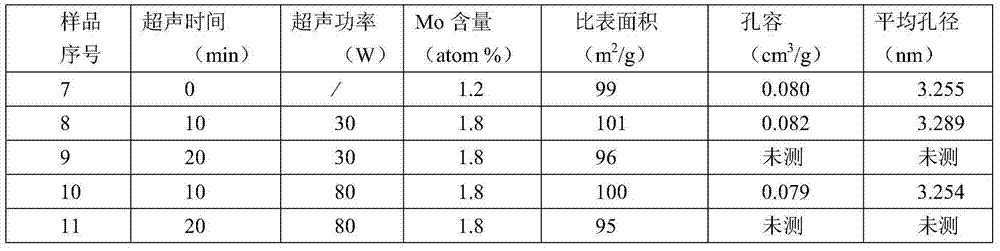

[0028] Adopt the same method as embodiment 1 to prepare novel Raney nickel catalyst, difference is, molybdate contains molybdenum gram number and ratio of Raney nickel weight gram number is 0.03, dropwise finishes and continues to stir 10min, ultrasonic probe power is 30W or 80W. Some structural parameters of the catalysts prepared under these conditions are listed in Table 3.

[0029] Table 3 Structural parameters of the new modified Raney nickel obtained under different ultrasonic treatment times

[0030]

[0031] The above catalyst is used to hydrogenate sorbitol from glucose, and the initial pressure of the hydrogenation reaction is P H2 =1.2MPa, the reaction temperature was controlled at 383K, and the reaction was carried out in a 200mL stainless steel autoclave. Initially, 0.5g of the new Raney nickel catalyst and 40mL of glucose solution (40%wt%) were added, and the reaction time was 2h. The results are shown in Table 4.

[0032] The glucose hydrogenation activity ...

Embodiment 3

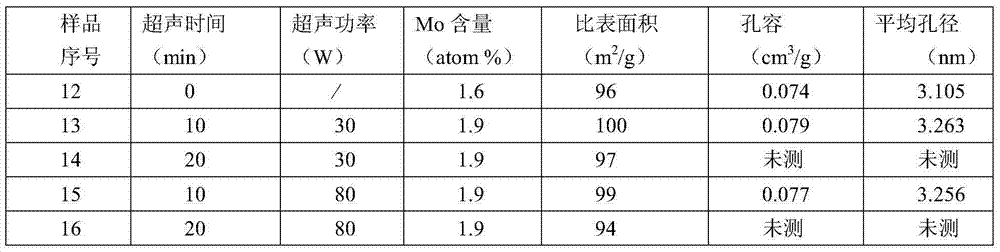

[0036] Adopt the method identical with embodiment 1 to prepare framework nickel-phosphorus catalyst, difference is, molybdate contains molybdenum gram number and Raney nickel weight gram number ratio is 0.10, dropwise finishes and continues to stir 30min, and ultrasonic probe power is 30W or 80W. Some structural parameters of the catalysts prepared under these conditions are listed in Table 5.

[0037] Table 5 Structural parameters of the new modified Raney nickel obtained under different ultrasonic treatment times

[0038]

[0039] The above catalyst is used to hydrogenate sorbitol from glucose, and the initial pressure of the hydrogenation reaction is P H2 =1.2MPa, the reaction temperature was controlled at 383K, and the reaction was carried out in a 200mL stainless steel autoclave. Initially, 0.5g of the new Raney nickel catalyst and 40mL of glucose solution (40%wt%) were added, and the reaction time was 2h. The results are shown in Table 6.

[0040] The glucose hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com