Thin steel plate narrow welding joint online visual inspection and control device

A visual inspection and control device technology, applied in auxiliary devices, comprehensive factory control, electrical program control, etc., can solve single problems, achieve the effects of saving human resources, speeding up welding, and facilitating centralized monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. The embodiments are carried out on the premise of the technical solution of the present invention, and detailed implementation methods and specific operation processes are given, but the protection scope of the claims of the application is not limited to the following embodiments.

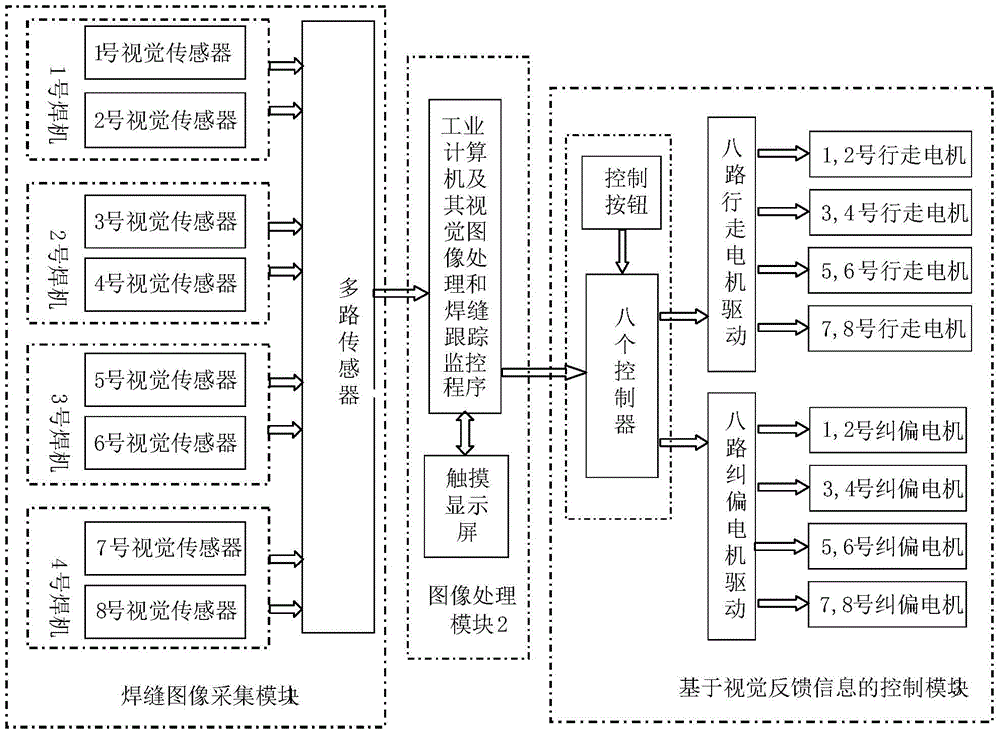

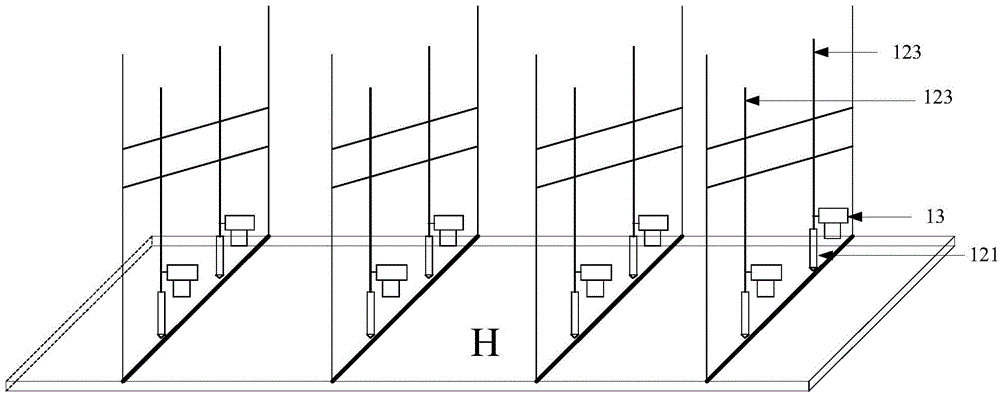

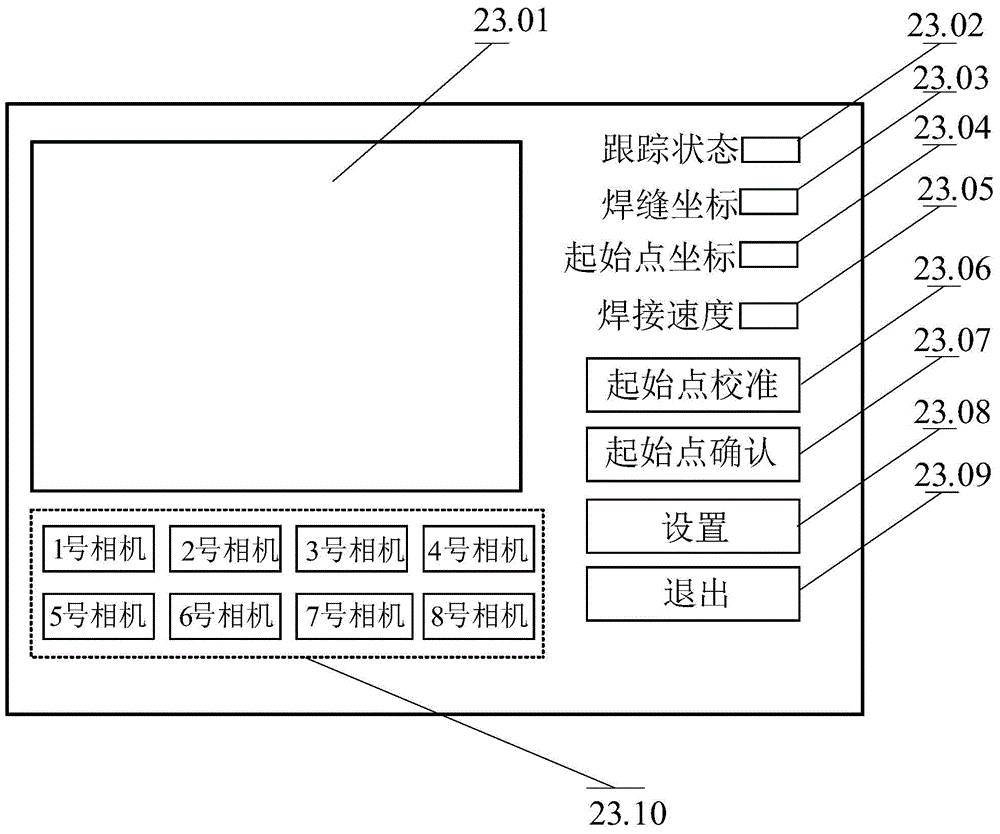

[0020] On-line visual detection and control device for thin steel plate narrow weld seam designed by the present invention (referred to as device, see Figure 1-4 ), characterized in that the device includes three major modules: a weld image acquisition module 1, an image processing module 2, and a control module 3 based on visual feedback information, wherein the weld image acquisition module 1 communicates with the image processing module 2 through a USB interface line are connected, and the image processing module 2 is connected with the control module 3 based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com