Hydrophilic/hydrophobic sewage dephosphorization coagulant and preparation method thereof

A coagulant, water and sewage technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of large sludge, difficult treatment, increased water treatment costs, etc., to achieve less residual pollutants, less environmental load, clear water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of hydrophilic / hydrophobic sewage phosphorus removal coagulant, it is prepared according to the following steps:

[0037] (1) Pretreatment of raw materials: use industrial waste slag as raw material and grind it into a powder of less than 100 meshes. The industrial waste slag comes from an aluminum factory in Shandong. The main components are: Al2 o 3 The content is 23.82wt%, Fe 2 o 3 The content is 23.05wt%, SiO 2 The content is 21.65wt%, Na 2 The O content is 17.36wt%, the CaO content is 1.34wt%, the loss on ignition is 12.75wt%, and the balance is a very small amount of impurities;

[0038] (2) Preparation of active solution: make concentrated sulfuric acid into dilute sulfuric acid with a volume fraction of 10%, add surfactant sodium dodecylbenzene sulfonate and mix evenly to form an active solution, and the surfactant accounts for the volume fraction of the solution 0.30%;

[0039] (3) Activation of raw materials: Mix the pretreated raw material powder ...

Embodiment 2

[0044] A kind of hydrophilic / hydrophobic sewage phosphorus removal coagulant, it is prepared according to the following steps:

[0045] (1) Pretreatment of raw materials: industrial waste slag is used as raw material, and it is ground into a powder of less than 100 mesh; the waste slag comes from a smelter in Hubei, and its main component is: Al 2 o 3 The content is 19.45wt%, Fe 2 o 3 The content is 24.03wt%, SiO 2 The content is 29.51wt%, Na 2 The O content is 1.54wt%, the CaO content is 2.31wt%, the loss on ignition is 23.14wt%, and the balance is impurities;

[0046] (2) Preparation of active solution: make concentrated sulfuric acid into dilute sulfuric acid with a volume fraction of 15%, add surfactant sodium lauryl sulfate, and the volume fraction of surfactant in the solution is 0.23%;

[0047] (3) Activation of raw materials: Mix the pretreated raw materials and the active solution at a weight ratio of 1:2, then add them to the reaction kettle, stir and react at 1...

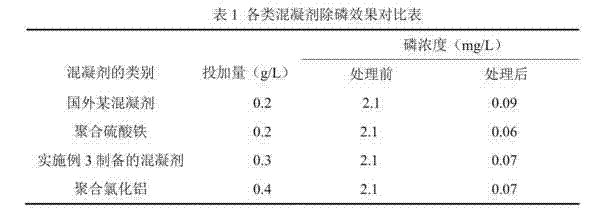

Embodiment 3

[0050] A kind of hydrophilic / hydrophobic sewage phosphorus removal coagulant, it is prepared according to the following steps:

[0051] (1) Pretreatment of raw materials: industrial waste slag is used as raw material and ground into a powder of less than 100 mesh; industrial waste slag is used as raw material and ground into a powder of less than 100 mesh; the waste slag comes from a smelter in Hubei, and its main component is: Al 2 o 3 The content is 19.45wt%, Fe 2 o 3 The content is 24.03wt%, SiO 2 The content is 29.51wt%, Na 2 The O content is 1.54wt%, the CaO content is 2.31wt%, the loss on ignition is 22.16wt%, and the balance is impurities;

[0052] (2) Preparation of active solution: make concentrated sulfuric acid into dilute sulfuric acid with a volume fraction of 15%, add surfactant sodium dodecylbenzenesulfonate, and the volume fraction of the surfactant in the solution is 0.12%;

[0053] (3) Activation of raw materials: Mix the pretreated raw materials and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com