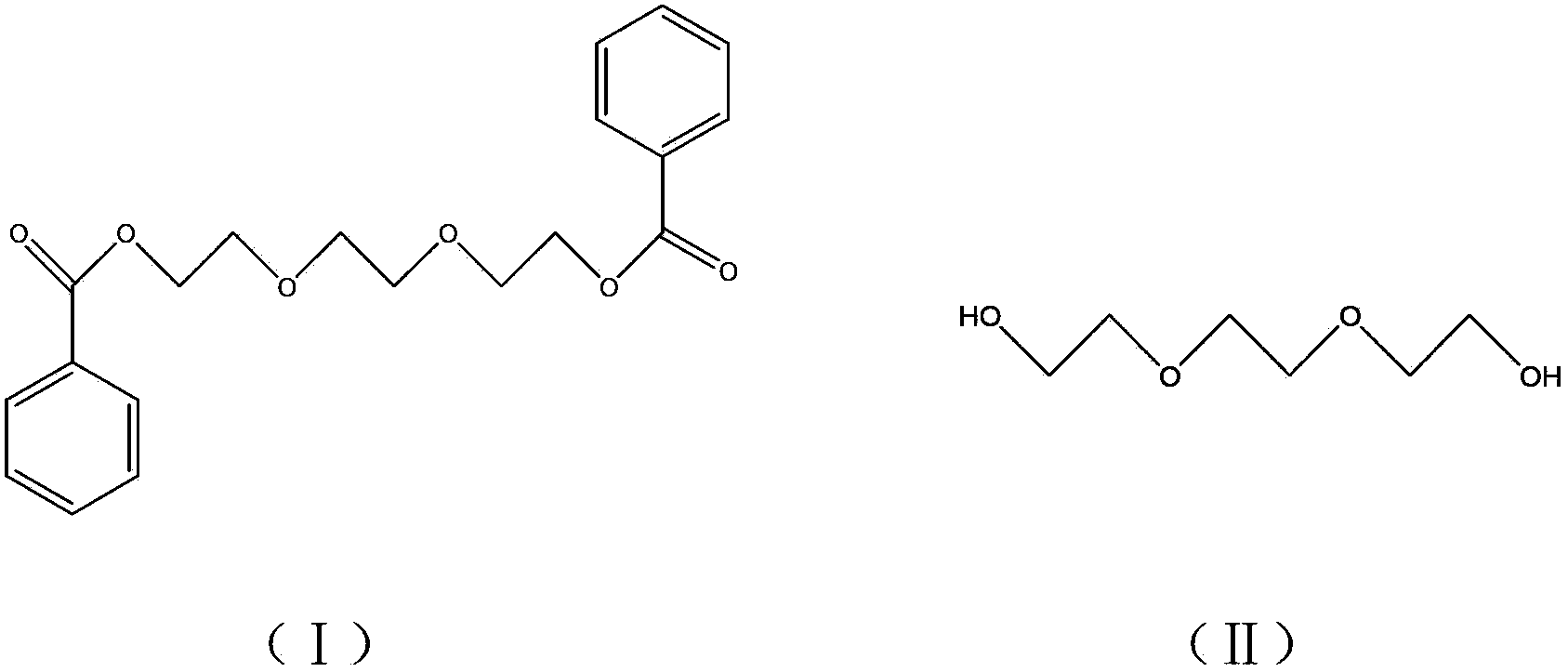

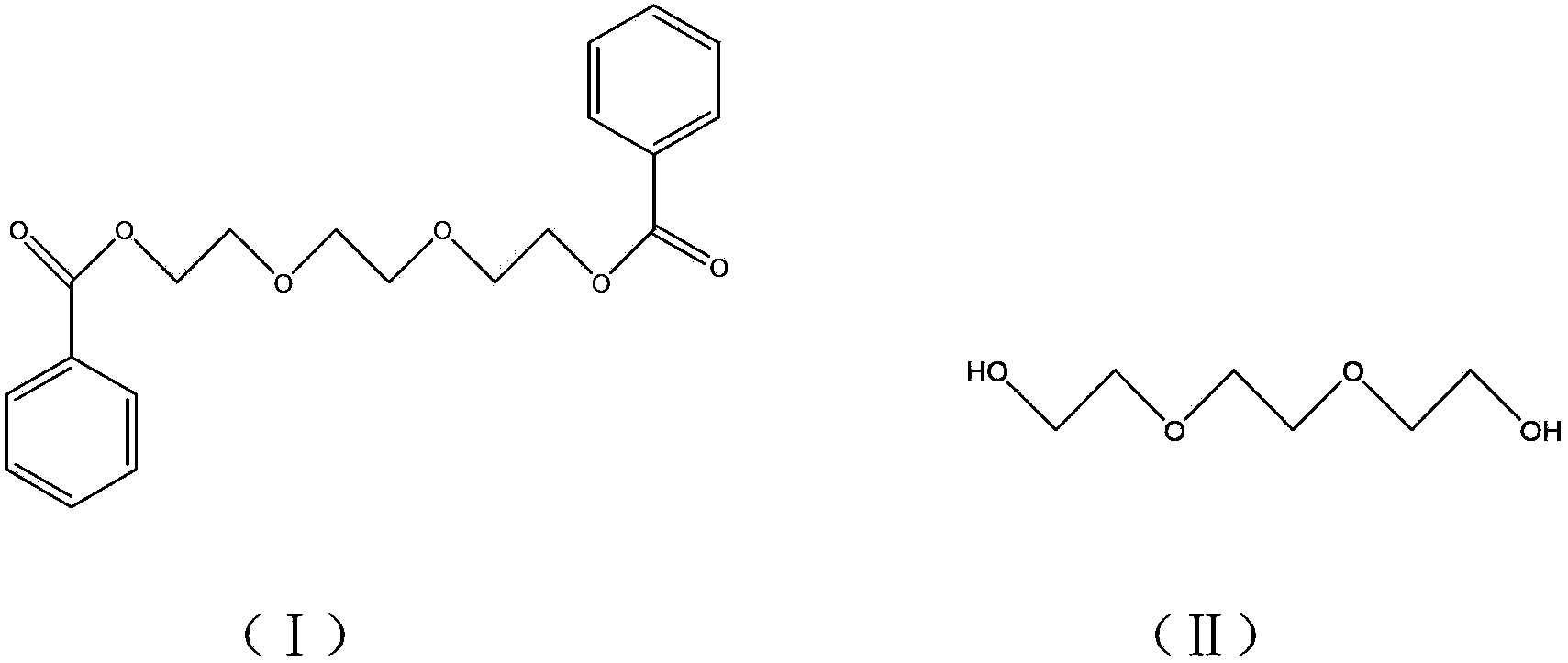

Preparation method of triethylene glycol dibenzoate

A technology of triethylene glycol dibenzoate and benzoate, applied in the field of preparation of triethylene glycol dibenzoate, can solve problems such as unfavorable large-scale production, sewage treatment and the like, and is suitable for large-scale industrial The effect of production, easy separation, environmental protection or safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

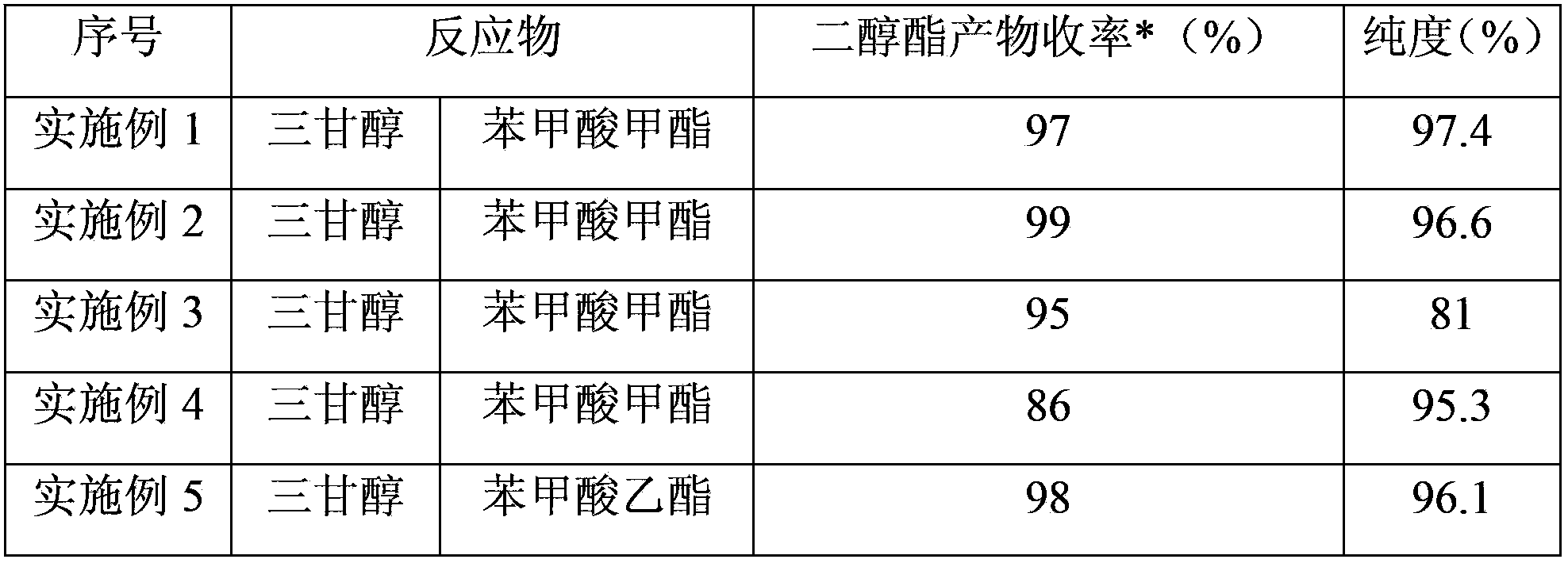

Examples

Embodiment 1

[0029] This embodiment is used to illustrate the preparation method of triethylene glycol dibenzoate provided by the invention.

[0030]Add 30g (0.2mol) triethylene glycol (gas chromatography content 99.2%; containing 0.8% diethylene glycol) and 108.9g (0.8mol) benzoic acid into a 250mL round bottom flask with condenser, liquid separator and stirrer Methyl ester, 5.5g (0.04mol) anhydrous potassium carbonate, heat the oil bath in contact with the round bottom flask to 155°C, react at 0.1MPa, and distill the generated alcohol to the separator and remove it by distillation during the reaction , after reacting for 6 hours, add toluene in the round bottom flask, add 6 times in total, the time interval between two adjacent additions is 2.1 hours, add 12mL each time, react for 2 hours after each addition of toluene and simultaneously add toluene and The azeotrope was distilled out of the round bottom flask, and the next toluene was added after the reaction liquid was cooled for about...

Embodiment 2

[0035] This embodiment is used to illustrate the preparation method of triethylene glycol dibenzoate provided by the invention.

[0036] Add 22.53g (0.15mol) triethylene glycol (gas chromatography content 99.2%; containing 0.8% diethylene glycol) and 81.69g (0.6mol) benzoic acid into a 150mL single-necked flask with a condenser, separator, and stirrer Methyl ester, 2.07g (0.015mol) anhydrous potassium carbonate, heat the oil bath in contact with the single-necked flask to 155°C, react at 0.1MPa, and distill the generated alcohol to the liquid separator by distillation during the reaction and remove it, After reacting for 6 hours, add xylene to the single-necked flask, add 6 times in total, the time interval between two adjacent additions is 2.1 hours, add 12mL each time, heat the oil bath that contacts the single-necked flask after adding xylene each time To 170°C, react for 2 hours and distill xylene and azeotrope out of the single-necked flask at the same time, wait for the ...

Embodiment 3

[0038] This example is used to illustrate the preparation of triethylene glycol dibenzoate by using anhydrous potassium carbonate supported on a carrier alumina as a catalyst provided by the present invention.

[0039] (1) Preparation of catalyst loaded with anhydrous potassium carbonate onto alumina

[0040] The neutral alumina was calcined at 550°C for 4 hours before use. Dry anhydrous potassium carbonate in a blast drying oven at 105°C for 3 hours, take 6g of dried anhydrous potassium carbonate and dissolve it in 40mL of deionized water, add 24g of neutral alumina after fully dissolved, and let it stand for 24 hours after fully stirring. The mixture was put into an evaporating dish to evaporate the water to dryness, and then put into a blast drying oven to dry at 105° C. for 24 hours. The obtained solid was calcined in a muffle furnace at 600° C. for 5 hours to obtain 28.89 g of a catalyst powder in which anhydrous potassium carbonate was supported on alumina.

[0041] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com