Photoinduced-deformation high polymer material based on triplet state-triplet state annihilation up-conversion luminescence

A technology of polymer materials and conversion materials, applied in the field of photoresponsive polymer materials, can solve problems such as not found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 The structural formula of the material is:

[0041]

[0042] Platinum Tetraphenylbenzoporphyrin (PtTPBP) 9-10-Diphosphorylphenylanthracene (YN2)

[0043] In this embodiment, a polymer bilayer film material is prepared by mechanical pressure-induced bonding. The up-conversion materials selected in this example are the sensitizer palladium octaethylporphyrin and the annihilate 9,10-diphenylanthracene, and the liquid crystal polymer material is a liquid crystal polymer film formed after polymerization of A9ABT and C9A.

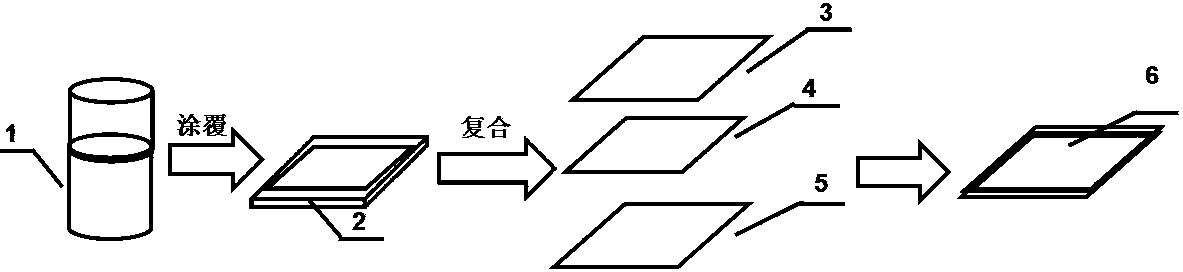

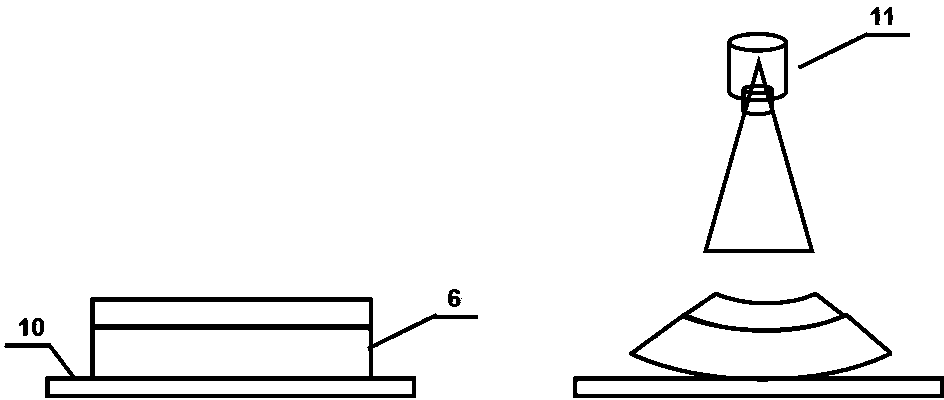

[0044] see figure 1 As shown, tetraphenylbenzoporphyrin palladium and YN2 were first dissolved in polyurethane N, N'-dimethylformamide solution, and then the mixed suspension was coated on a glass substrate and dried to form a film. Then, the surface of the prepared polyurethane film mixed with PtTPBP and YN2 is coated with polyacrylate adhesive, and bonded with the liquid crystal polymer film. Then press up and down with a flat press pl...

Embodiment 2

[0045] Embodiment 2 The structural formula of the material is:

[0046]

[0047] Palladium Octaethylporphyrin (PdOEP) 9,10-Diphenylanthracene (DPA)

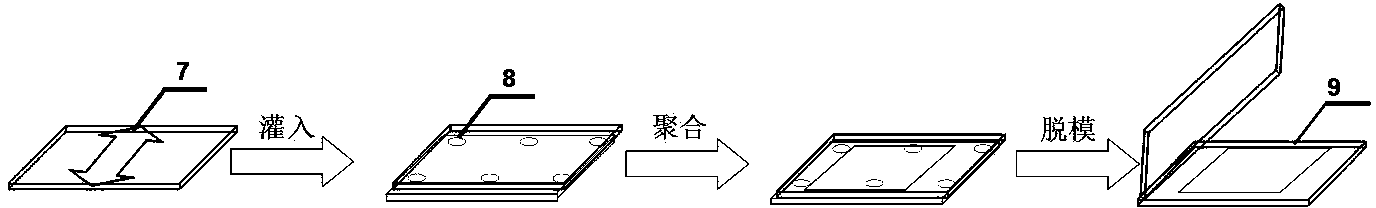

[0048] In this embodiment, a liquid crystal polymer composite film is prepared by thermal polymerization in the in-situ polymerization method. see figure 2 Shown: First mix A9ABT and C9A in a molar ratio of 4:6, then add 5% thermal initiator azobisisobutylcyanide of the sum of the molar numbers of A9ABT and C9A, and then add the sum of the mass of A9ABT and C9A 5 % octaethylporphyrin palladium and 9,10-diphenylanthracene. After mixing evenly, pour it into a liquid crystal cell made of two substrates. The substrate is coated with an orientation-treated polyimide film, and a spacer material with a certain diameter is placed between the two substrates to maintain a certain distance so as to control the thickness of the liquid crystal polymer composite film. Control the temperature at 120° C., polymerize for 24 hours, and op...

Embodiment 3

[0049] The structural formula of embodiment 3 material is:

[0050]

[0051] Octabutoxyphthalocyanine palladium rubrene

[0052] In this embodiment, the photopolymerization method in the in-situ polymerization method is used to prepare the liquid crystal polymer composite film. join figure 2 As shown, first mix A11AB6 and DA11AB in a molar ratio of 90:10, then add A11AB6 and DA11AB molar sum of 5% photoinitiator, then add A11AB6 and DA11AB mass sum of 5% octabutoxy phthalocyanine palladium and rubrene mixture. After mixing evenly, pour it into a liquid crystal cell made of two substrates. The substrate is coated with an orientation-treated polyimide film, and a spacer material with a certain diameter is placed between the two substrates to maintain a certain distance so as to control the thickness of the liquid crystal polymer composite film. Use a heating platform to control the temperature at 100°C, and when the wavelength emitted by the light source is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com