Flame-retardant PET (polyethylene glycol terephthalate) heat shrink film and preparation method thereof

A heat-shrinkable film and flame retardant technology, applied in the field of flame-retardant PET heat-shrinkable film and its preparation, can solve the problem of no research and report on PET heat-shrinkable film, and achieve the effects of preventing spontaneous combustion, preventing fire, and having strong shrinkage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

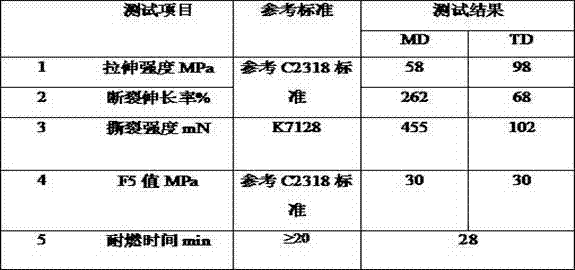

Embodiment 1

[0022] A flame-retardant PET heat-shrinkable film, mainly made of the following raw materials in parts by weight: 80 parts of PET resin, 5 parts of decabromodiphenylethane, 1 part of HANKINS NCP-2, 2 parts of zinc stearate, phthalate 1 part of dibutyl diformate.

[0023] A method for preparing a flame-retardant PET heat-shrinkable film, comprising the following steps: weighing the raw materials in the above parts by weight;

[0024] Add PET resin, decabromodiphenylethane, HANKINS NCP-2, zinc stearate, and dibutyl phthalate into the reactor at 75°C, and stir at 150 rpm for 10 minutes; raise the temperature in the reactor To 290°C, the pressure drops below 90pa, and react under this condition for 2~3h to obtain a polymer melt, then extrude the prepared polymer melt, cut into pellets, and dry to obtain PET polyester chips; the above PET polyester chips Melt extrusion, die casting, casting sheet winding, biaxial stretching, cooling and setting, thickness measurement, winding, sli...

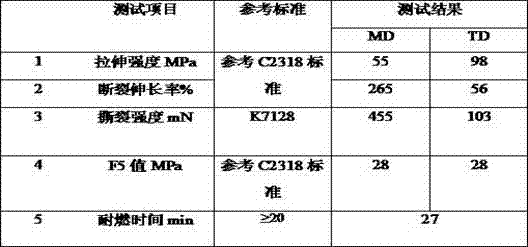

Embodiment 2

[0027] A flame-retardant PET heat-shrinkable film, which is mainly made of the following raw materials in parts by weight: 90 parts of PET resin, 10 parts of brominated epoxy resin, 5 parts of HANKINS NCP-2, 5 parts of ethylene bisstearamide, 3 parts of dibutyl phthalate.

[0028] The preparation method of the flame-retardant PET heat-shrinkable film comprises the following steps: weighing the raw materials in the above-mentioned parts by weight; adding PET resin, brominated epoxy resin, HANKINS NCP-2, and ethylene bis-stearin Amide, dibutyl phthalate, and stirred at 200rpm for 20min; the temperature in the reactor was raised to 300°C, and the pressure was lowered to below 90pa. Under these conditions, the polymer melt was obtained by reacting for 3h, and then the prepared polymer Melt extrusion, pelletizing, and drying to obtain PET polyester chips; melt extrusion of the above PET polyester chips, die casting, casting sheet winding, biaxial stretching, cooling and setting, th...

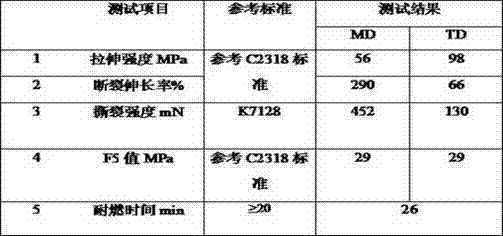

Embodiment 3

[0031] A flame-retardant PET heat-shrinkable film, mainly made of the following raw materials in parts by weight: 85 parts of PET resin, 7 parts of brominated polystyrene, 3 parts of HANKINS NCP-2, 3 parts of high melting point paraffin, phthalic acid 2 parts of dibutyl ester.

[0032] The preparation method of flame-retardant PET heat-shrinkable film comprises the following steps: weighing the raw materials of the above-mentioned parts by weight; adding PET resin, brominated polystyrene, HANKINS NCP-2, high melting point paraffin, ortho Dibutyl phthalate, and stirred at 180rpm for 15min; the temperature in the reactor was raised to 295°C, and the pressure was lowered to below 90pa. Under these conditions, the reaction was carried out for 2.5h to obtain a polymer melt, and then the prepared polymer melt Extrude, pelletize, and dry to obtain PET polyester chips; melt and extrude the above PET polyester chips, die casting, winding, biaxial stretching, cooling and setting, thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com