Method for enhancing sintering of high-proportion limonite by utilization of waste heat of exhaust gas

A limonite, high-proportion technology, applied in the field of limonite sintering, can solve the problems of insignificant reduction of water evaporation and heat absorption, increase of sintering processing cost, and increase of high-temperature process, so as to improve quality indicators and reduce sintering energy consumption , The effect of reducing heat expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

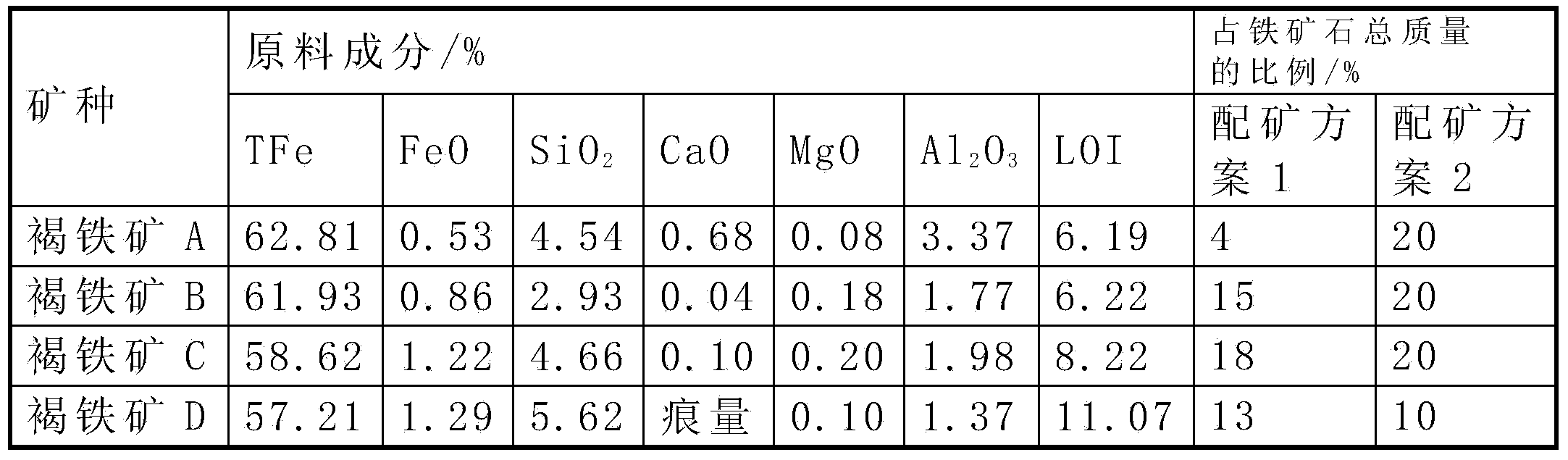

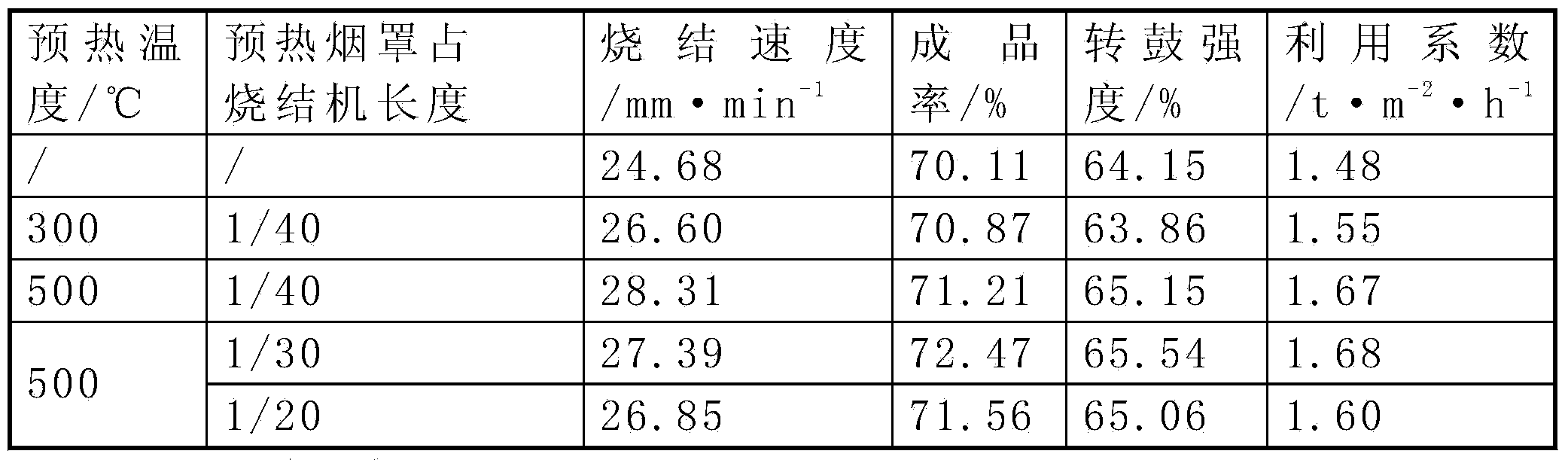

[0023] Four kinds of limonites are added into the sintered material, and the chemical compositions of various limonites are shown in Table 1. When the total amount of limonite accounts for 50% of the total amount of iron ore, the proportions of various limonites are shown in Table 2, ore blending scheme 1, and the chemical composition of the produced sinter is TFe58.5%, R1.7, SiO 2 4.9%, MgO1.5%. After the mixture is distributed and sintered and ignited, a sealed fume hood is added, and high-temperature exhaust gas is introduced to heat the mixture to remove the crystal water and free water in the mixture on the surface of the material layer. The high-temperature exhaust gas comes from the ring cooler I For the cooling exhaust gas of Section or Section II, the position of the fume hood is located at the head of the sintering machine, between the distribution device and the ignition fume hood. It can be seen from Table 2 that in the range where the hot air temperature is 300-...

Embodiment 2

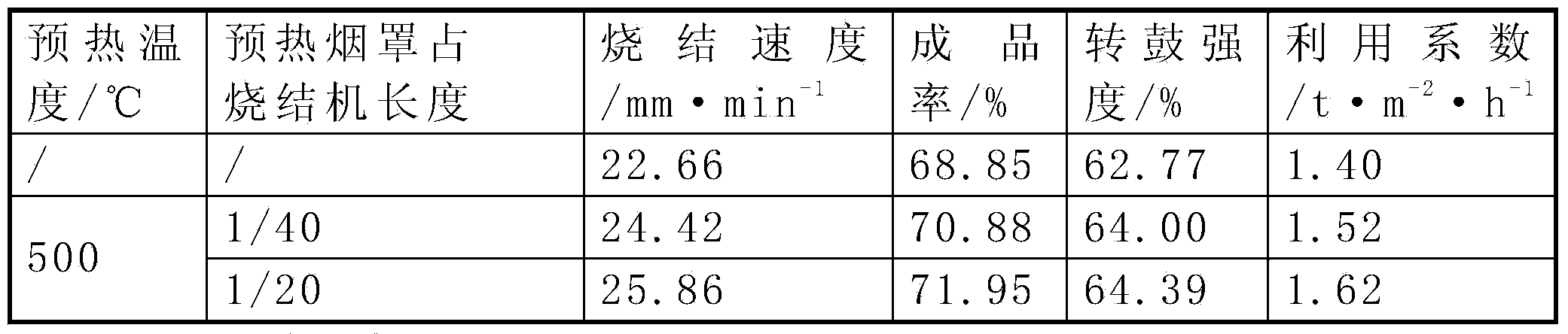

[0025] Four kinds of limonites are added into the sintered material, and the chemical compositions of various limonites are shown in Table 1. When the total amount of limonite accounts for 70% of the total amount of iron ore, the proportions of various limonites are shown in Table 3, ore blending scheme 2, and the chemical composition of the produced sinter is TFe57.3%, R1.9, SiO 2 5.0%, MgO2.0%. After the mixture is distributed and sintered and ignited, a sealed fume hood is added, and high-temperature exhaust gas is introduced to heat the mixture, remove the crystal water and free water in the mixture on the surface of the material layer, and the high-temperature exhaust gas is extracted from the tail of the sintering machine for the last 1- High temperature flue gas from 2 bellows, the position of the hood is located at the head of the sintering machine, between the distribution device and the ignition hood. It can be seen from Table 3 that the use of waste gas waste heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com