Method for preparing blast furnace ironmaking burden from full-vanadium titanium magnetite concentrate

A technology of vanadium-titanium magnetite concentrate and vanadium-titanium magnetite, which is applied in the field of preparing high-quality blast furnace ironmaking charge, can solve the problems of high alkalinity sintering technology limitation, reduce the grade of total iron in sintered ore, etc., and achieve the promotion of oxidation and heat release , to avoid a large number of production, good development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

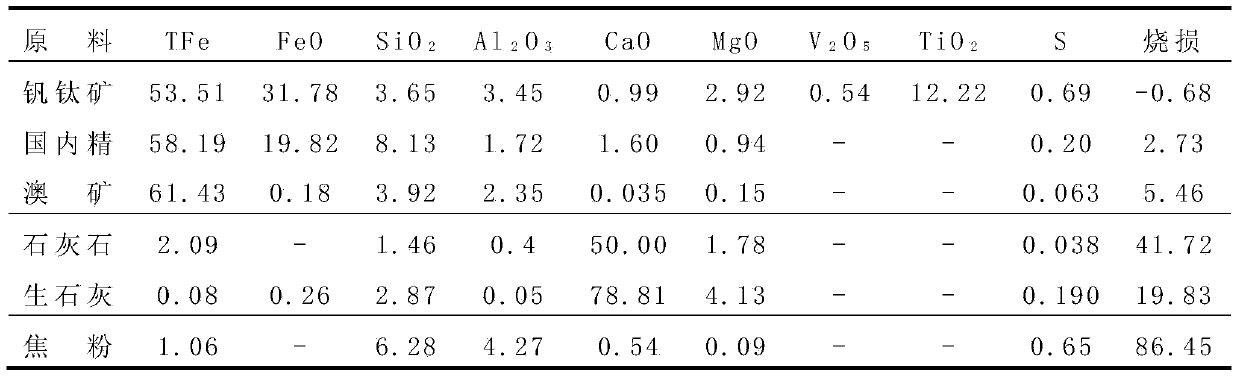

Image

Examples

Embodiment 1

[0028]A single vanadium-titanium magnetite concentrate is used as the iron-containing raw material, the amount of coke powder is 3.9%, the basicity of the comprehensive material is 2.0, and 30% is returned to the ore. The whole vanadium-titanium magnetite concentrate is divided into two parts according to the mass percentage of 60%:40%, and 60% of the vanadium-titanium magnetite concentrate is agglomerated separately, and after being prepared into a spherical material with a particle size of 3mm to 7.5mm, it is rolled outside The mass percentage of the spherical material is 0.1% slaked lime to obtain a low-alkalinity spherical material with an alkalinity of 0.29 and a particle size of less than 8mm; the remaining 40% of the vanadium-titanium magnetite concentrate is mixed with all coke powder, flux and returned ore, and granulated. Prepare a high alkalinity mixture with an alkalinity of 3.9; then mix all the low alkalinity spherical materials and the ultrahigh alkalinity mixtur...

Embodiment 2

[0030] A single vanadium-titanium magnetite concentrate is used as the iron-containing raw material, the amount of coke powder is 3.9%, the basicity of the comprehensive material is 2.2, and the externally mixed ore is 30%. The whole vanadium-titanium magnetite concentrate is divided into two parts according to the mass percentage of 65%: 35%, and 65% of the vanadium-titanium magnetite concentrate is agglomerated separately, and after being prepared into a spherical material with a particle size of 4mm to 6.5mm, it is rolled outside The mass percentage of the spherical material is 0.18% slaked lime to obtain a low-alkalinity spherical material with an alkalinity of 0.3 and a particle size of less than 8mm; the remaining 35% vanadium-titanium magnetite concentrate is mixed with all coke powder, flux and returned ore, and granulated. Prepare a high alkalinity mixture with an alkalinity of 4.0; then mix all the low alkalinity spherical materials and the ultrahigh alkalinity mixtur...

Embodiment 3

[0032] A single vanadium-titanium magnetite concentrate is used as the iron-containing raw material, the amount of coke powder is 3.9%, the basicity of the comprehensive material is 1.8, and the externally mixed ore is 30%. The whole vanadium-titanium magnetite concentrate is divided into two parts according to the mass percentage of 60%:40%, and 60% of the vanadium-titanium magnetite concentrate is separately granulated into a spherical material with a particle size of 3mm to 5mm, and the spherical material is rolled outside The mass percentage is 0.5% slaked lime, obtains the low alkalinity mixed material that alkalinity is 0.38, particle size is less than 8mm; Mix remaining 40% vanadium-titanium magnetite concentrate with all coke powder, flux and returned ore, granulate, and prepare into The high alkalinity mixture with an alkalinity of 3.6; after mixing all the low alkalinity spherical materials and the ultrahigh alkalinity mixture evenly, the cloth is placed on a belt sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com