Hydraulic speed retarding device adopting engine oil as medium

An engine oil and hydraulic retarding technology, which is applied in the direction of engine components, engine lubrication, machine/engine, etc., can solve the problems of increasing the volume, quality, cost and assembly difficulty of hydraulic retarding devices, and achieve compact structure, Simplified structure and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

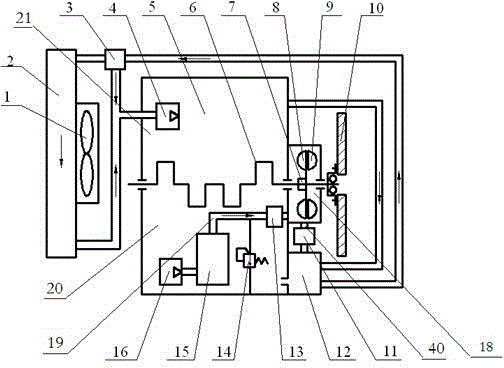

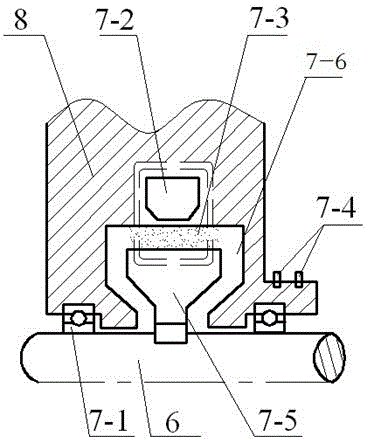

[0026] Such as figure 1 , 3 , shown in 4, an engine oil medium type hydraulic retarder, including a hydraulic retarder and a control unit that can control the work of the hydraulic retarder, the hydraulic retarder is installed on the vehicle engine crankshaft 6 and flywheel 10 between, and the hydraulic retarder has a retarder working chamber 18, which also includes an inlet pipe 19, an outlet pipe 40, an engine oil pump 16, and an inlet throttle valve 13 for controlling the oil flow in the inlet pipe 19 and controlling the outlet pipe Outlet throttle valve 11 for engine oil circulation in 40, engine oil pump 16 is arranged in engine oil chamber 20, engine oil pump 16, inlet pipe 19, slow speed working chamber 18, outlet pipe 40 and engine oil chamber 20 are connected in sequence A circulation pipeline is formed, the inlet throttle valve 13 is connected to the inlet pipeline 19, the outlet throttle valve 11 is connected to the outlet pipeline 40, and the inlet throttle valve ...

Embodiment 2

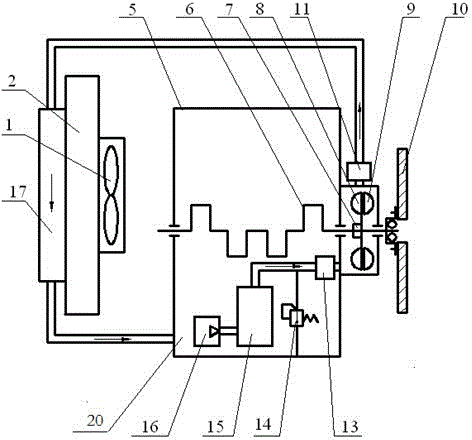

[0040] Such as figure 2 As shown, the present embodiment is similar to Embodiment 1, and the difference is that the oil cooler includes an oil radiator 17 and an engine radiator 2, the oil radiator 17 is installed on the engine radiator 2, and the oil inlet end of the oil radiator 17 It communicates with the outlet throttle valve 11 , and the oil outlet of the oil radiator 17 communicates with the engine oil chamber 20 . This embodiment cancels the oil-water heat exchanger 12 in the first embodiment, but is provided with a special oil radiator 17, which is installed in front of the engine radiator 2. When the hydraulic retarder is working, after energy absorption and heating The engine oil enters the engine oil radiator 17 from the top through the outlet throttle valve 11, and the engine oil after being cooled by the natural wind of the vehicle and the cooling fan 1 directly returns to the engine oil chamber 20, so that the continuous circulation will make the hydraulic retar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com