An optical fiber output photoelectric encoder

A photoelectric encoder and encoder technology, applied in the field of photoelectric encoders, can solve the problems of electrical working parts affected by the environment, use restrictions, and high waterproof requirements, and achieve high bandwidth, enhanced insulation performance, and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

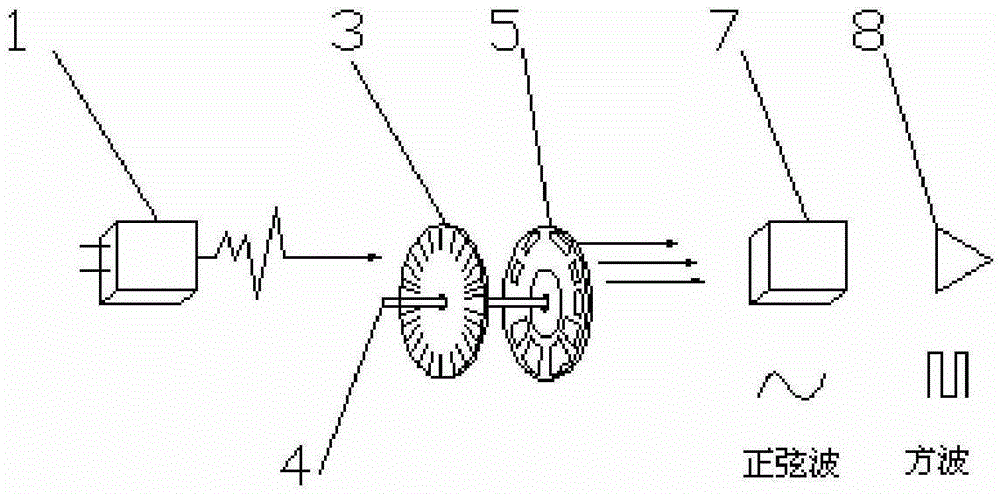

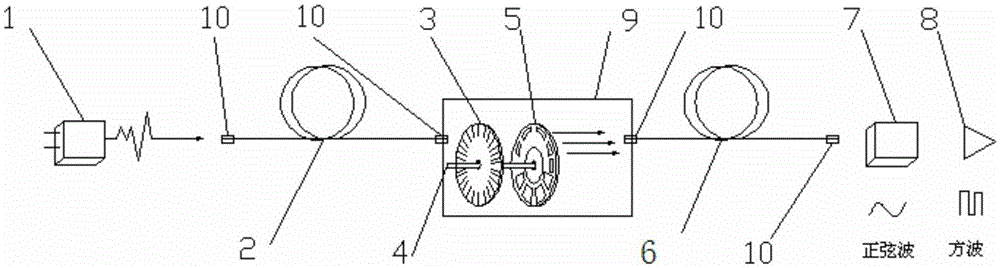

[0030] Embodiment 1: Optical encoder for optical fiber output of rotational parameters in oil gas or corrosive environment.

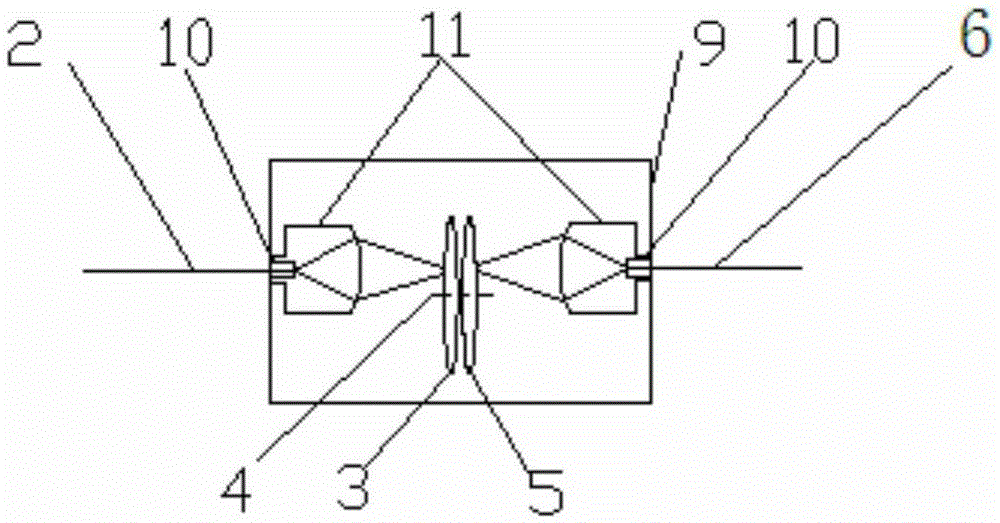

[0031] refer to image 3 , Example 1 with figure 2 The difference in structure is that two collimators 11 are added, which are respectively located between the input optical fiber 2 and the code disc 3 , and between the slit disc 5 and the output optical fiber 6 .

[0032] The light source 1 is an infrared light-emitting diode, the receiver 7 is a silicon phototransistor, the input optical fiber 2 and the output optical fiber 6 are plastic optical fibers, and the length of the transmission part of the input optical fiber 2 and output optical fiber 6 is 30m. The code disc 3 is a rotary type, and is placed in the encoder housing 9 together with the slit disc 5 and the support shaft 4. The code disc 3 adopts a matrix pattern, and the base material of the code disc 3 is K9 optical glass. The diameter of the code disc depends on the 3 digits, the diameter...

Embodiment 2

[0033] Embodiment 2: A photoelectric encoder for measuring rotation and angle parameters in a high-voltage environment with optical fiber output.

[0034] refer to Figure 4 , Example 2 with figure 2 The difference in structure is that a focusing lens 13 or a focusing lens group is added, which is located between the input optical fiber 2 and the code wheel 3 .

[0035]The light source 1 is an infrared light-emitting diode, the receiver 7 is a silicon phototransistor, the input optical fiber 2 and the output optical fiber 6 are multi-component glass optical fibers, and the length of the transmission part of the input optical fiber 2 and output optical fiber 6 is 1000m. The code disc 3 is a translational type. It is placed in the encoder housing 9 together with the slit disc 5 and the support shaft 4. The code disc 3 is engraved with radial light-transmitting slits with equal pitches. Between two adjacent light-transmitting slits The interval represents an incremental period...

Embodiment 3

[0036] Embodiment 3: A photoelectric encoder with optical fiber output for measuring rotation and angle parameters in a deep-sea environment.

[0037] refer to Figure 5 , Example 3 with figure 2 The structural difference is that a collimating device 14 is provided between the input optical fiber 2 and the code disk 3 , and a focusing device 15 is provided between the slit disk 5 and the output optical fiber 6 .

[0038] The light source 1 is a near-infrared laser, the receiver 7 is a silicon phototransistor, the input fiber 2 and the output fiber 6 are pure silicon core bending-resistant quartz fibers, and the length of the transmission part of the input fiber 2 and output fiber 6 is 8000m. The code disc 3 is a rotary type, and is placed in the encoder housing 9 together with the slit disc 5 and the support shaft 4. The slit disc 5 is engraved with a single slit (light-transmitting slit) corresponding to the 9-bit code disc 3 .

[0039] The input optical fiber 2 and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com