Method for designing magnetism-keeping parallel stepping swinging stretchy joint

A design method and magnetic retention technology, applied in the direction of electromagnet, motor generator control, electromagnet with armature, etc., can solve the problem of only turning, unable to meet the requirements of high-end technology, single robot joint and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

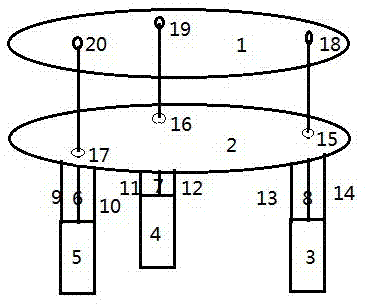

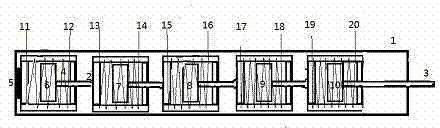

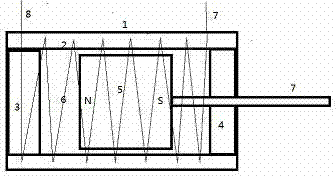

[0006] The magnetically held parallel step swing telescopic joint works under the action of the processor and the encoder. When the processor gives a positive pulse voltage to a certain unit in the magnetically held parallel step driver, the magnetically held drive passes through the peripheral circuit. , a positive pulse current will be given to the magnetic holding driver of this unit, and the magnetic holding driver of this unit will move forward, and the encoder will record the state of the magnetic holding driver of this unit. A reverse voltage of a magnetic holding driver of a certain unit, through the peripheral circuit, will give a reverse pulse current to the magnetic holding driver of this unit, the magnetic holding driver of this unit will retract backward, and the encoder will record this unit The state of the magnetic holding drive, and a sensor is installed at the front or rear end of each unit magnetic holding drive. The state of each unit magnetic holding drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com