Method for extracting olive polyphenol from olive processing waste liquor

A technology for olive polyphenols and processing waste liquid, which can be applied in pharmaceutical formulations, non-central analgesics, medical preparations containing active ingredients, etc., can solve problems such as environmental pollution and resource waste, and achieve high purity and extraction and separation efficiency. The effect of high and good potential for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

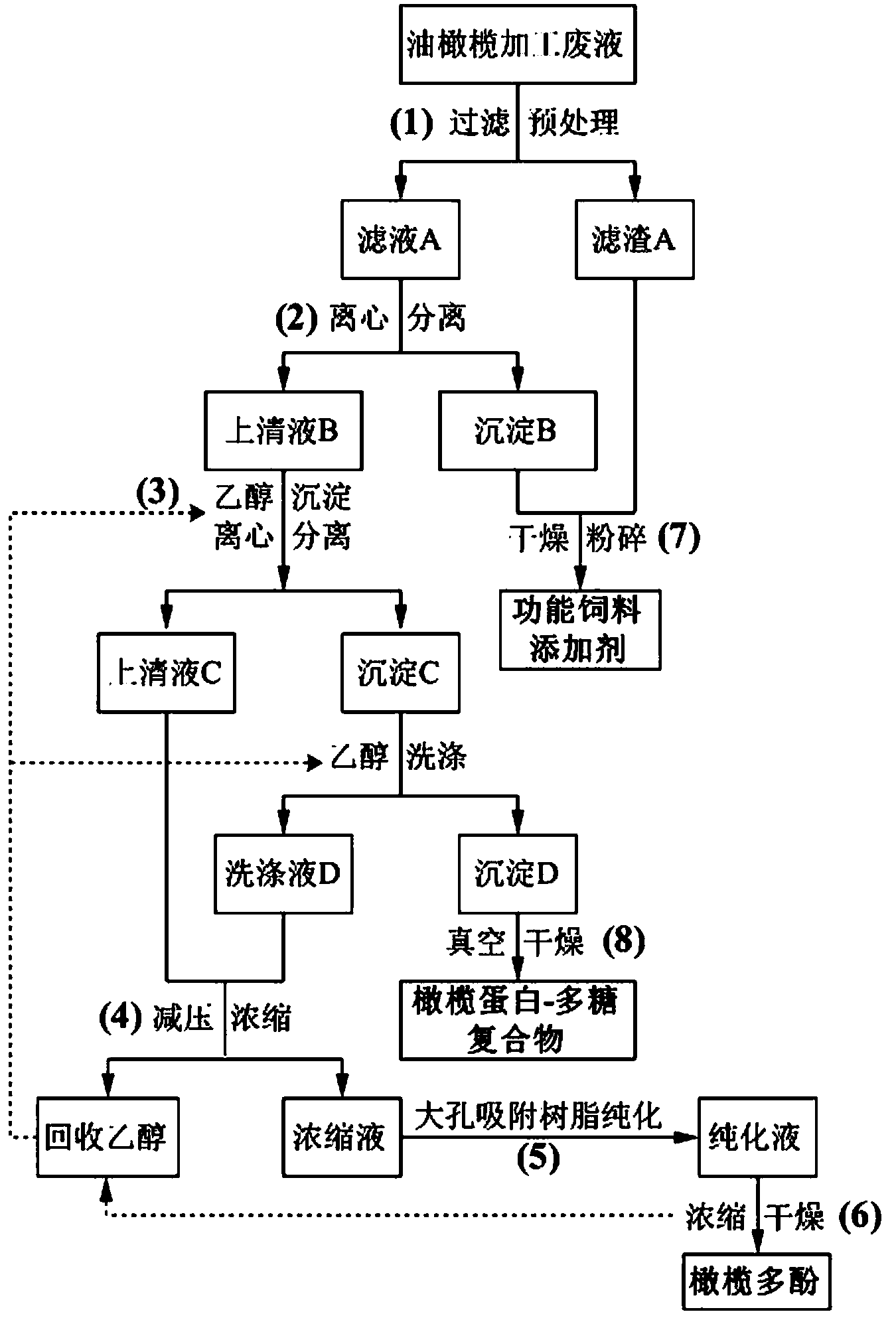

[0020] Take 1000 mL of fresh olive processing waste liquid (polyphenol content is 4.6 g / L), and filter it with 80 mesh filter cloth to obtain filter residue A and filtrate A. Filtrate A is centrifuged at 2000 rpm for 30 min to obtain supernatant B and precipitate B , mix filter residue A and precipitate B, dry and pulverize with hot air to obtain a functional feed additive.

[0021] Add absolute ethanol to the supernatant B so that the volume percentage of ethanol in the mixture is 20%, stir well and precipitate at 0°C for 2 h, and centrifuge the mixture at 2000 rpm for 30 min to obtain supernatant C and precipitate C; Precipitate C was washed with 50% ethanol solution until the washing liquid was colorless, washing liquid D and precipitate D were collected, and precipitate D was vacuum-dried or freeze-dried to obtain the olive polysaccharide-protein complex.

[0022] Combine supernatant C and washing solution D, recover ethanol after concentrating under vacuum and decompressi...

Embodiment 2

[0024] Take 800 mL of fresh olive processing waste liquid (polyphenol content is 4.2 g / L), and filter it with a 100-mesh filter cloth to obtain filter residue A and filtrate A. Filtrate A is centrifuged at 3000 rpm for 20 min to obtain supernatant B and precipitate B , mix filter residue A and precipitate B, dry and pulverize with hot air to obtain a functional feed additive.

[0025] Add absolute ethanol to the supernatant B to make the volume fraction of ethanol in the mixture 30%, stir well and precipitate at 5 °C for 4 h, and centrifuge the mixture at 3000 rpm for 20 min to obtain supernatant C and precipitate C, Precipitate C was washed with 60% ethanol aqueous solution until the washing liquid was colorless, washing liquid D and precipitate D were collected, and precipitate D was vacuum-dried or freeze-dried to obtain the olive polysaccharide-protein complex.

[0026] Combine the supernatant C and the washing solution D, concentrate and recover ethanol under vacuum to ob...

Embodiment 3

[0028] Take 600 mL of waste liquid from fresh olive processing (polyphenol content is 2.9 g / L), and filter it with a 150-mesh filter cloth to obtain filter residue A and filtrate A. Filtrate A is centrifuged at 4000 rpm for 15 min to obtain supernatant B and precipitate B , mix filter residue A and precipitate B, dry and pulverize with hot air to obtain a functional feed additive.

[0029] Add absolute ethanol to the supernatant B so that the volume fraction of ethanol in the mixture is 40%. After fully stirring, precipitate at 10 °C for 6 h. The mixture is centrifuged at 4000 rpm for 15 min to obtain supernatant C and precipitate C. Precipitate C was washed with 70% ethanol aqueous solution until the washing liquid was colorless, washing liquid D and precipitate D were collected, and precipitate D was vacuum-dried or freeze-dried to obtain the olive polysaccharide-protein complex.

[0030] Combine the supernatant C and the washing solution D, concentrate and recover ethanol u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com