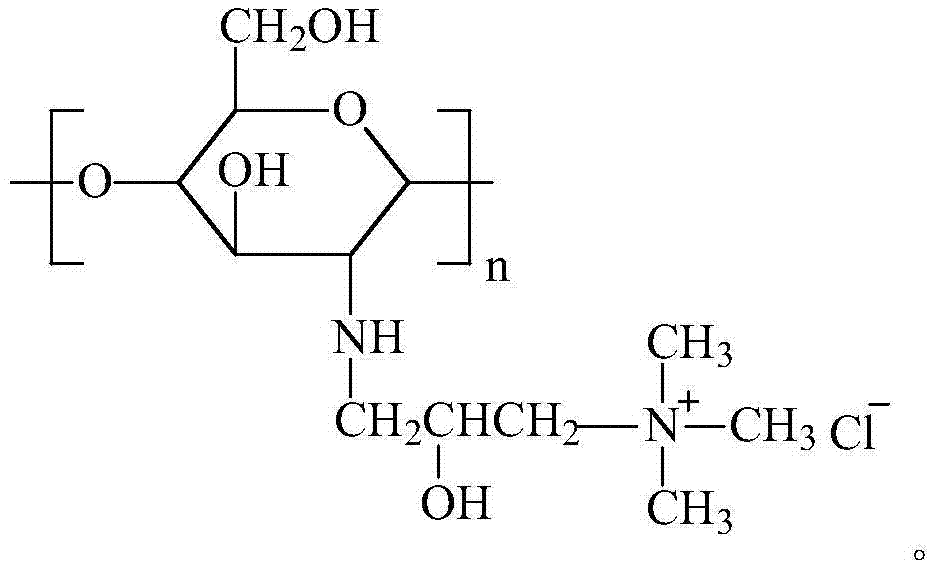

Method for preparing quaternized chitosan modified polysulfone ultrafiltration membrane

A technology of quaternized chitosan and polysulfone ultrafiltration membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Simple preparation method and improved hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Put 19g of polysulfone and 1g of anhydrous zinc chloride into 70g of N-methylpyrrolidone, heat and stir to dissolve into a casting solution, vacuum defoam the solution for 2 hours, let it stand for 2 hours, and spread the solution evenly Cover the polyester non-woven fabric, scrape the liquid film into a uniform thickness with a scraper, and immerse it in pure water to undergo a phase inversion reaction to form a film.

[0018] The removal rate of the membrane for bovine serum albumin is 97.5%, and the pure water flux is 45L / m 2 .h.

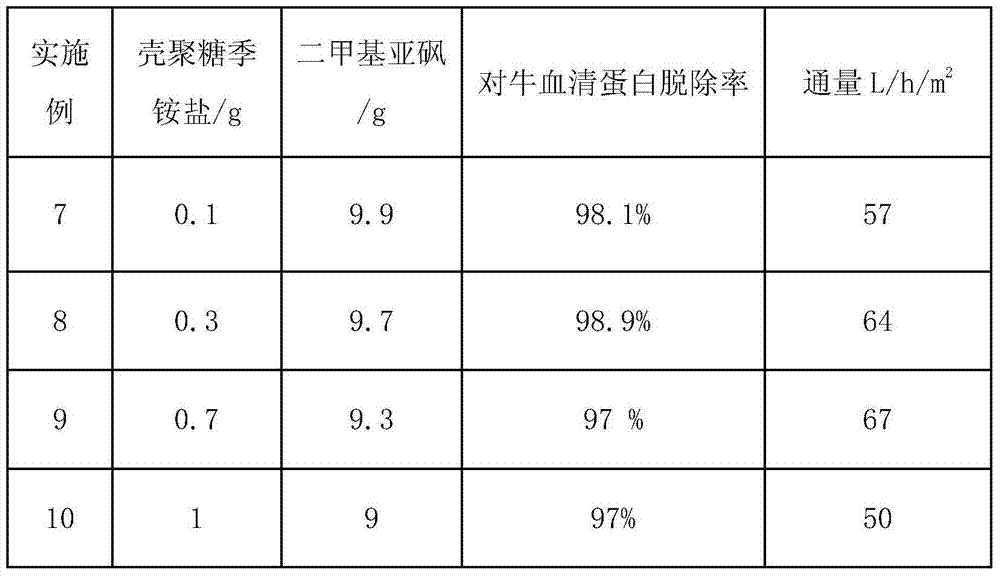

Embodiment 2

[0020] Put 19g of polysulfone and 1g of anhydrous zinc chloride into 70g of N-methylpyrrolidone, heat at 60°C and stir to dissolve into a homogeneous solution A. The dissolution process after heating is easier and more convenient, and the uniformity of dissolution is better; Put 0.5g of quaternized chitosan into 9.5g of dimethyl sulfoxide and stir to dissolve into a homogeneous solution B, and use the solution blending method to mix the two solutions of A and B into a homogeneous solution, which is the required casting solution , after vacuum degassing the mixed solution for 2 hours, let it stand for another 2 hours to ensure that the air bubbles in the mixed solution are removed, apply the solution evenly on the polyester non-woven fabric, and scrape the liquid film into a uniform thickness with a scraper Finally, immerse into pure water to form a phase inversion reaction to form a film. The above-mentioned film scraping process is a conventional method in the industry, and th...

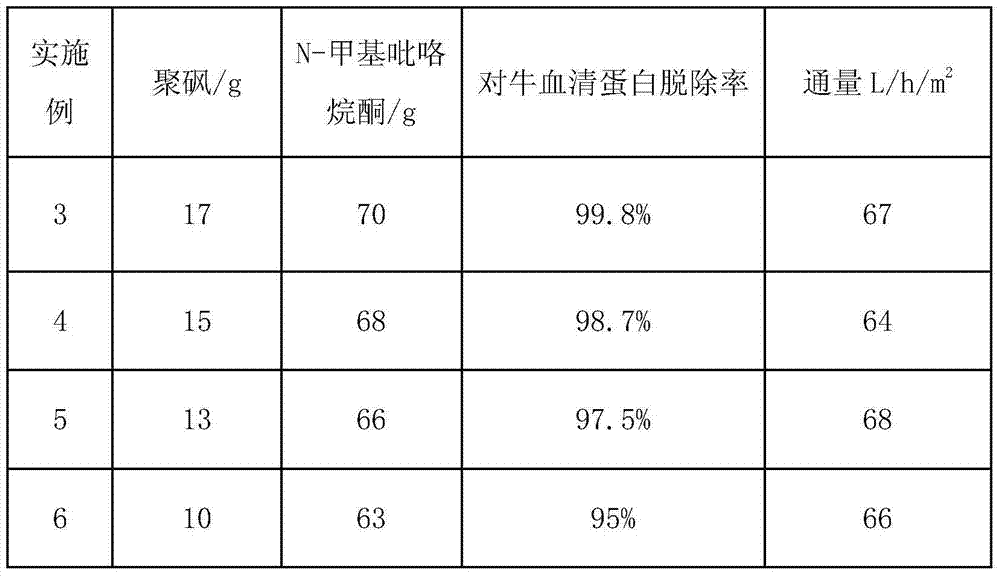

Embodiment 3-6

[0023] According to the same steps of Example 2, change the feeding amount of polysulfone and N-methylpyrrolidone in the A solution, other steps are the same as in Example 2, prepare a composite membrane and test, the results are as follows:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com