Preparation method of thermo-magnetic dual responsive mesoporous silicon microspheres

A dual-response, mesoporous silicon technology, applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of non-targeting and lower bioavailability of drugs, and achieve good biocompatibility properties, good application prospects, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

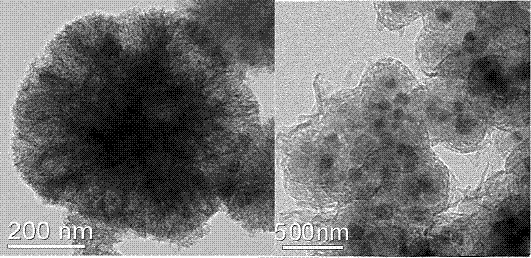

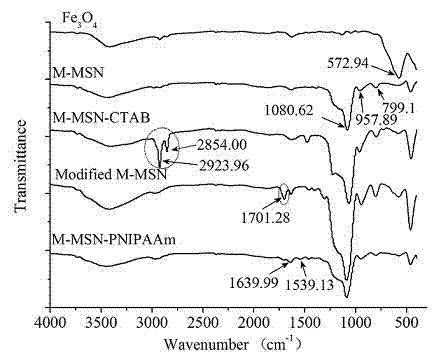

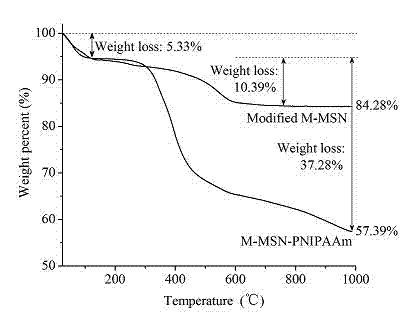

[0024] (1) Synthesis of magnetic nanoparticles. Superparamagnetic nanoparticles were synthesized by co-precipitation method, the specific process is as follows: Weigh 1.45 g FeSO 4 ·7H 2 O and 1.62 g FeCl 3 Dissolve in 100 mL of deionized water, fill with N 2 Divide O 2 After 20 min, when the water temperature was heated to 60°C under stirring, 5 mL of ammonia water was quickly added, and the mixed solution immediately turned black. After the mixed solution was reacted for 60 min, the black product was separated with a permanent magnet, washed with deionized water 4 times to remove residual ammonia, and finally placed in a 40° C. vacuum oven for drying for subsequent use. (2) Fe 3 o 4 SiO 2 Preparation of nanoparticles. Weigh 0.12 g of the superparamagnetic Fe prepared above 3 o 4 Nanoparticles were ultrasonically dispersed into 80 mL of absolute ethanol, then 5 mL of ammonia water was added, and 1 mL of TEOS was added drop by drop under stirring conditions, and reac...

Embodiment 2

[0026] (1) Synthesis of magnetic nanoparticles. Superparamagnetic nanoparticles were synthesized by co-precipitation method, the specific process is as follows: Weigh 2.24g FeSO 4 ·7H 2 O and 2.46 g FeCl 3 Dissolve in 100mL deionized water, fill with N 2 Divide O 2 After 30 min, when the water temperature was heated to 60°C with stirring, 10 mL of ammonia water was added quickly, and the mixed solution immediately turned black. After the mixed solution was reacted for 60 min, the black product was separated with a permanent magnet, washed with deionized water four times to remove residual ammonia, and finally dried in a vacuum oven at 50 °C for future use. (2) Fe 3 o 4 SiO 2 Preparation of nanoparticles. Weigh 0.25g of the superparamagnetic Fe prepared above 3 o 4 Nanoparticles were ultrasonically dispersed into 90 mL of absolute ethanol, then 5 mL of ammonia water was added, and 1 mL of TEOS was added drop by drop under stirring conditions, and reacted at room tempe...

Embodiment 3

[0028] (1) Synthesis of magnetic nanoparticles. Superparamagnetic nanoparticles were synthesized by co-precipitation method, the specific process is as follows: Weigh 3.25g FeSO 4 ·7H 2 O and 3.45 g FeCl 3 Dissolve in 100 mL of deionized water, fill with N 2 Divide O 2 60min, when the water temperature was heated to 60 °C under the condition of stirring, 5mL ammonia water was added rapidly, and the mixed solution turned black immediately. After the mixed solution was reacted for 60 min, the black product was separated with a permanent magnet, washed with deionized water 4 times to remove residual ammonia, and finally dried in a vacuum oven at 60°C for future use. (2) Fe 3 o 4 SiO 2 Preparation of nanoparticles. Weigh 0.5 g of the above-prepared superparamagnetic Fe 3 o 4 Nanoparticles were ultrasonically dispersed into 100 mL of absolute ethanol, then 5 mL of ammonia water was added, and 1 mL of TEOS was added drop by drop under stirring conditions, and reacted at ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com